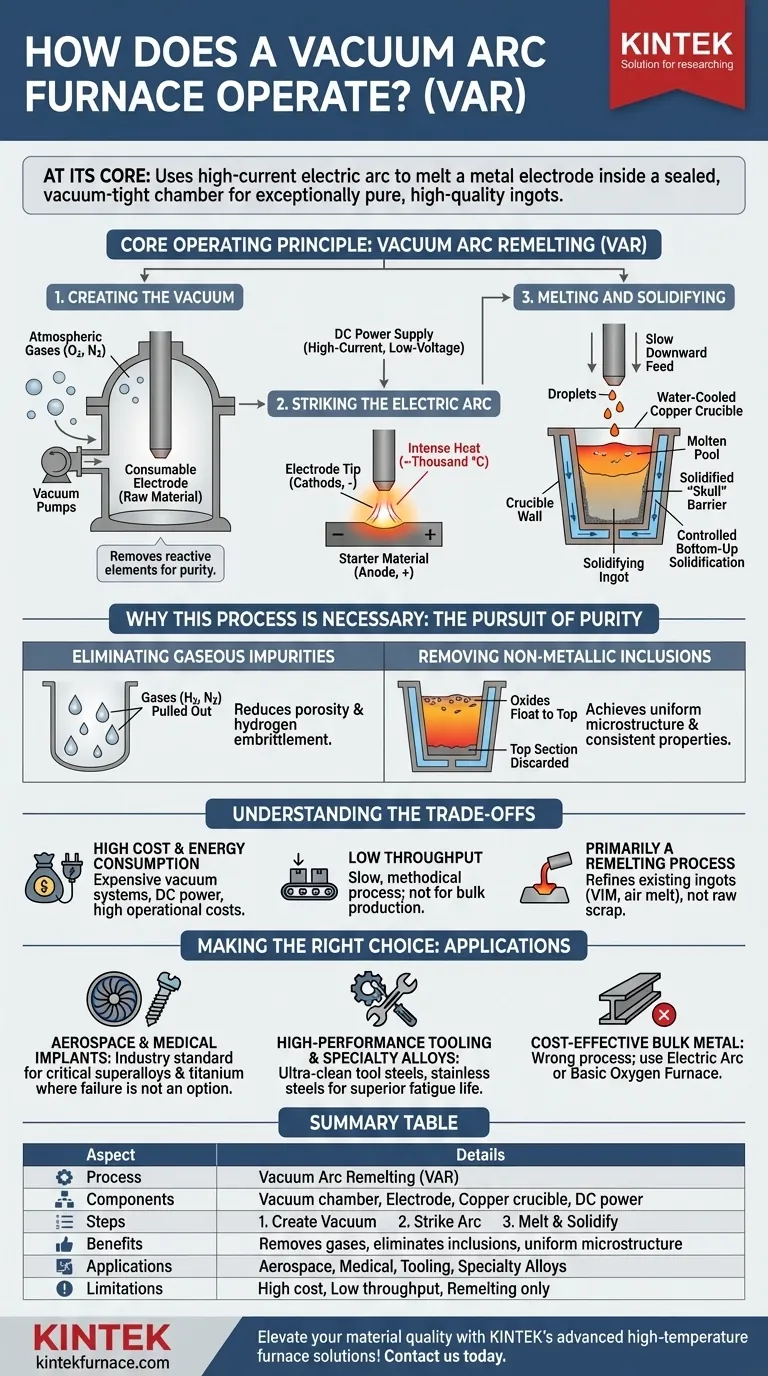

At its core, a vacuum arc furnace uses a high-current electric arc to melt a metal electrode inside a sealed, vacuum-tight chamber. The intense heat from the arc melts the material, while the vacuum prevents it from reacting with atmospheric gases like oxygen and nitrogen, resulting in an exceptionally pure, high-quality final ingot.

The fundamental problem a vacuum arc furnace solves is material contamination. By combining the intense, localized energy of an electric arc with the purity of a vacuum, it refines metals to a level of cleanliness and structural integrity that is impossible to achieve in a standard air-based furnace.

The Core Operating Principle: Arc and Vacuum

The operation is a highly controlled, multi-stage process designed for ultimate refinement. It is most commonly referred to as Vacuum Arc Remelting (VAR), which highlights its role as a secondary melting process for purification.

Step 1: Creating the Vacuum

The process begins by placing the raw material, shaped into a large cylinder called a consumable electrode, inside a water-cooled copper crucible. The furnace is sealed, and a system of powerful pumps removes the air and other gases.

Creating this vacuum is the most critical step for ensuring purity. It removes the reactive elements that would otherwise form impurities, like oxides and nitrides, in the final product.

Step 2: Striking the Electric Arc

A high-current, low-voltage DC power supply is connected to the furnace. The consumable electrode acts as the negative terminal (cathode), and a small amount of starter material at the bottom of the crucible acts as the positive terminal (anode).

When power is applied, an electric arc is struck between the electrode tip and the base. This arc generates immense, focused heat, often reaching temperatures of several thousand degrees Celsius.

Step 3: Melting and Solidifying

The intense heat from the arc melts the tip of the consumable electrode. Molten metal droplets fall from the electrode into the water-cooled copper crucible below.

As the electrode is consumed, it is slowly fed downward to maintain a consistent distance, or arc gap. Simultaneously, the molten metal in the crucible cools and solidifies from the bottom up in a highly controlled manner, building the new, purified ingot layer by layer.

The Role of the Water-Cooled Crucible

The crucible is made of copper due to its extremely high thermal conductivity. It is aggressively water-cooled, which causes a thin layer of the molten metal to instantly solidify upon contact with the crucible wall.

This "skull" of solidified metal acts as an insulating barrier, preventing the molten pool from ever touching the copper crucible directly. This brilliantly engineered solution ensures the final ingot is not contaminated by the crucible material itself.

Why This Process Is Necessary: The Pursuit of Purity

The VAR process is not simply for melting metal; it is an active refining process that fundamentally improves the material's quality.

Eliminating Gaseous Impurities

As molten droplets fall through the vacuum, dissolved gases like hydrogen and nitrogen are literally pulled out of the metal. This significantly reduces the risk of porosity and hydrogen embrittlement in the final product.

Removing Non-Metallic Inclusions

The process creates a shallow pool of molten metal on top of the solidifying ingot. Less dense impurities, such as oxides, float to the top of this molten pool. As the ingot solidifies, these impurities are pushed upwards and concentrated at the very top, which is later cut off and discarded.

Achieving a Uniform Microstructure

The slow, directional solidification from the bottom up produces an ingot with a very uniform and predictable grain structure. This homogeneity is essential for achieving consistent mechanical properties, such as high fatigue strength and fracture toughness.

Understanding the Trade-offs

While the benefits are significant, the VAR process is not a universal solution. It comes with specific challenges and limitations.

High Cost and Energy Consumption

Vacuum arc furnaces are expensive to build, operate, and maintain. The required vacuum systems, high-current DC power supplies, and sophisticated control systems contribute to high capital and operational costs.

Low Throughput

Compared to primary melting techniques, VAR is a slow, methodical process. It is designed for quality, not quantity, making it unsuitable for the bulk production of commodity metals.

Primarily a Remelting Process

As the name "Vacuum Arc Remelting" implies, this is almost always a secondary step. You don't feed raw scrap into a VAR furnace. Instead, you use it to refine an ingot that was already created using another method, such as a vacuum induction melt (VIM) or even a standard air melt.

Making the Right Choice for Your Goal

The decision to use a vacuum arc furnace is driven entirely by the performance requirements of the final component.

- If your primary focus is aerospace components or medical implants: VAR is the industry standard. It is essential for producing the nickel-based superalloys and titanium alloys used in jet engine turbine disks, airframes, and biocompatible implants where material failure is not an option.

- If your primary focus is high-performance tooling or specialty alloys: VAR is used to create ultra-clean tool steels, stainless steels, and other alloys that demand superior fatigue life and exceptional cleanliness.

- If your primary focus is cost-effective bulk metal production: This is the wrong process. Standard methods like an Electric Arc Furnace (in air) or a Basic Oxygen Furnace are far more economical for structural steel and other general-purpose metals.

Ultimately, a vacuum arc furnace is a precision refining tool used to elevate good metals into exceptional materials for the world's most demanding applications.

Summary Table:

| Aspect | Details |

|---|---|

| Process Name | Vacuum Arc Remelting (VAR) |

| Key Components | Vacuum chamber, consumable electrode, water-cooled copper crucible, DC power supply |

| Operating Steps | 1. Create vacuum 2. Strike electric arc 3. Melt and solidify metal |

| Primary Benefits | Removes gaseous impurities, eliminates non-metallic inclusions, achieves uniform microstructure |

| Ideal Applications | Aerospace components, medical implants, high-performance tooling, specialty alloys |

| Limitations | High cost, low throughput, primarily a remelting process |

Elevate your material quality with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with precision equipment like Vacuum & Atmosphere Furnaces, CVD/PECVD Systems, and more. Our strong deep customization capability ensures we can precisely meet your unique experimental requirements for ultra-pure metals in aerospace, medical, and specialty alloy applications. Contact us today to discuss how our solutions can enhance your research and production outcomes!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What are the core functions of the High Vacuum Induction Melting (VIM) furnace? Optimize DD5 Superalloy Purification

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys