Operating a vacuum furnace requires a controlled environment that is free from hazardous substances and physical disturbances to ensure safety and optimal performance. Specifically, the operating area must be devoid of flammable and corrosive gases, and the equipment should be sited away from flammable materials, explosives, and water. Avoiding significant resonance during handling and operation is also critical for the furnace's integrity.

Core Takeaway

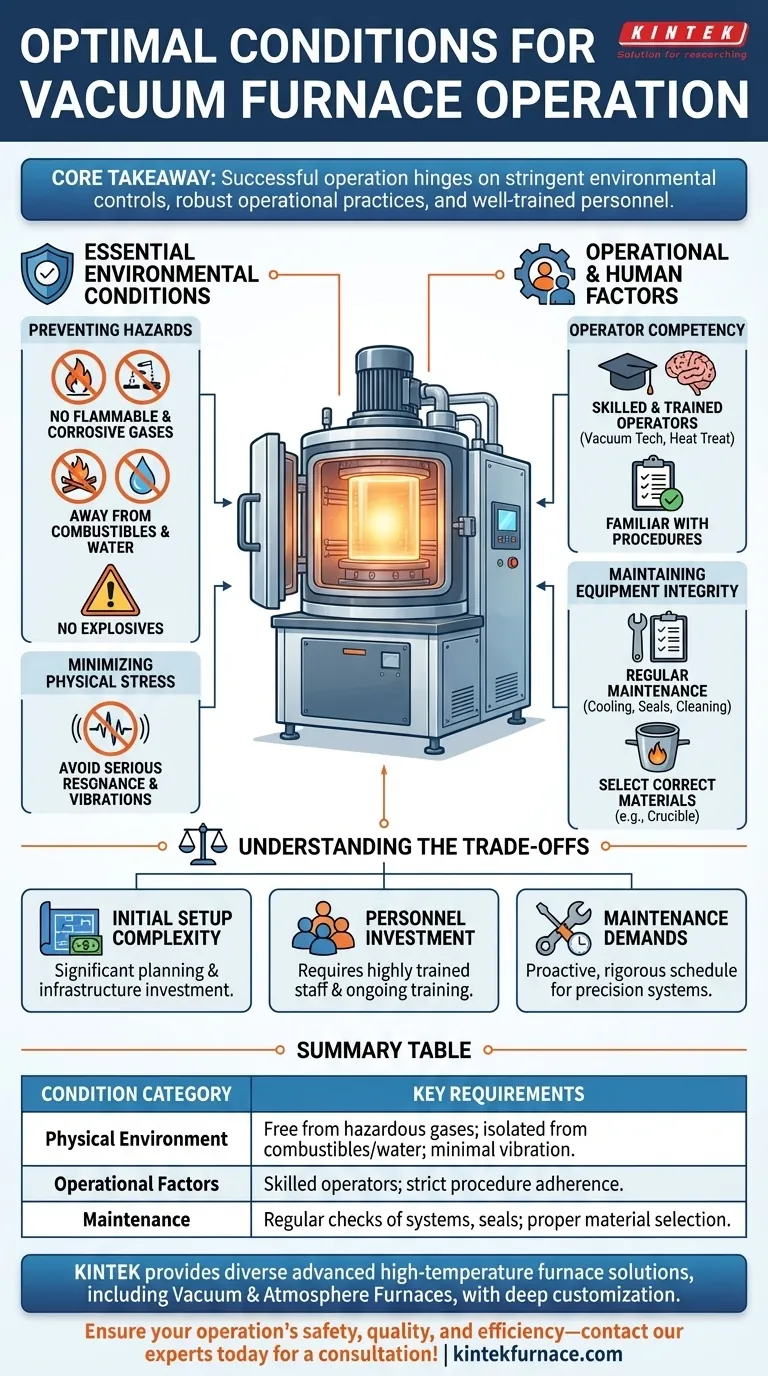

Successful vacuum furnace operation hinges on a combination of stringent environmental controls, robust operational practices, and well-trained personnel. Beyond physical placement, it demands careful attention to safety, regular maintenance, and skilled operators to prevent hazards, ensure process accuracy, and prolong equipment lifespan.

Essential Environmental Conditions

Preventing Hazards

To ensure safe operation, the physical environment surrounding a vacuum furnace must be carefully managed. This protects both the equipment and personnel.

Exclusion of Hazardous Substances

The working environment must be free from flammable and corrosive gases. These substances pose significant risks, including explosions, fires, and material degradation.

Isolation from Combustibles and Water

The furnace must be placed away from flammable materials, explosives, and water. Water can cause electrical shorts or other hazards, especially with high-temperature equipment.

Minimizing Physical Stress

Avoiding Resonance

During operation and handling, it is crucial to avoid serious resonance. Vibrations or mechanical shocks can compromise the furnace's delicate components and vacuum seals.

Operational and Human Factors

Beyond the immediate surroundings, the operational "environment" significantly impacts a vacuum furnace's performance and safety.

Operator Competency

Operating a vacuum furnace demands a high level of expertise.

Required Skills and Training

Operators must possess professional skills and knowledge in vacuum technology, heat treatment processes, and electrical control. Professional training is indispensable.

Familiarity with Procedures

Operators need to be thoroughly familiar with the equipment's operation methods and process requirements. This prevents errors that could affect both the equipment and product quality.

Maintaining Equipment Integrity

Regular Maintenance

Effective operation requires consistent maintenance. Key tasks include checking water cooling systems, inspecting the chamber and seals for vacuum leaks, and regular chamber cleaning.

Selecting Correct Materials

For induction-heated furnaces, selecting the correct crucible material for the specific application is vital for process success and equipment longevity.

Understanding the Trade-offs

While vacuum furnaces offer significant advantages, their stringent environmental and operational requirements represent inherent trade-offs compared to simpler heating methods.

Initial Setup Complexity

Establishing the required clean and isolated environment can involve significant planning and infrastructure investment, impacting initial project timelines and costs.

Personnel Investment

The necessity for highly trained and skilled operators means a greater investment in human resources, including ongoing training and certification.

Maintenance Demands

The precision nature of vacuum systems, especially seals and pumps, necessitates a proactive and rigorous maintenance schedule, which can be more involved than for atmospheric furnaces.

Making the Right Choice for Your Goal

Achieving successful and safe vacuum furnace operation requires aligning environmental controls, operational practices, and personnel expertise with your specific objectives.

- If your primary focus is safety and regulatory compliance: Prioritize a rigorously controlled environment, free from all specified hazardous substances and physical stressors, and invest heavily in operator training.

- If your primary focus is process reliability and product quality: Ensure operators are highly skilled and that a robust, scheduled maintenance program is in place, including regular checks of vacuum integrity and cooling systems.

- If your primary focus is equipment longevity and cost efficiency: Adhere strictly to proper operating procedures, perform all recommended maintenance, and address any signs of resonance or environmental contamination promptly.

By systematically addressing these environmental and operational factors, you can unlock the full potential of your vacuum furnace for precise and reliable material processing.

Summary Table:

| Condition Category | Key Requirements |

|---|---|

| Physical Environment | Free from flammable/corrosive gases; isolated from combustibles, explosives, and water; minimal vibration/resonance. |

| Operational Factors | Highly skilled operators trained in vacuum technology and heat treatment; strict adherence to procedures. |

| Maintenance | Regular checks of water cooling systems, vacuum seals, and chamber integrity; proper crucible material selection. |

Achieve precise and reliable material processing with a vacuum furnace tailored to your lab's unique needs.

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet your specific experimental requirements and environmental conditions.

Ensure your operation's safety, quality, and efficiency—contact our experts today for a consultation!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics