The vacuum environment acts as a critical process enabler that allows stainless steel powders to be sintered without chemical degradation.

In a vacuum hot press furnace, this environment serves two primary functions: it eliminates oxygen to prevent the material from rusting or oxidizing at high temperatures, and it physically removes trapped gases from between powder particles. This dual action is essential for creating stainless steel parts that are chemically pure and structurally dense.

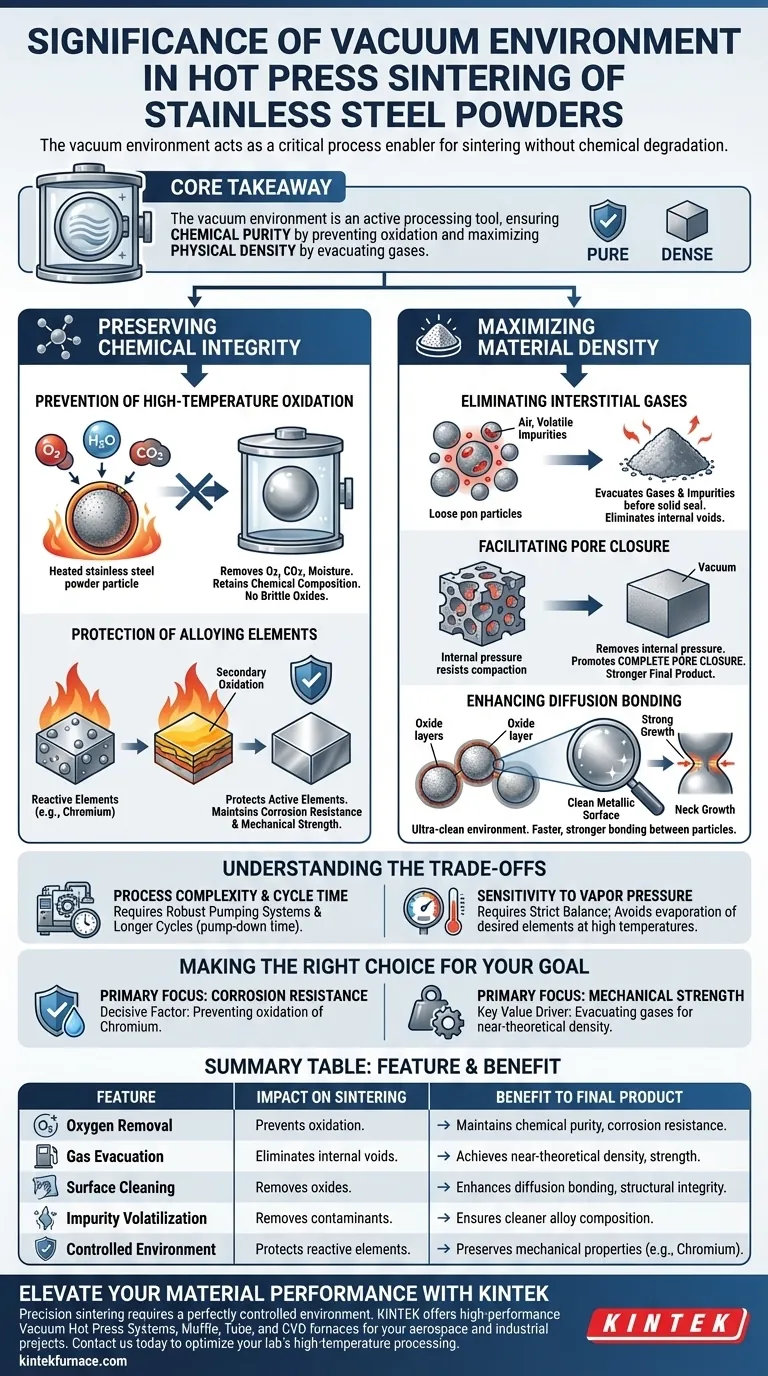

Core Takeaway The vacuum environment is not merely an absence of air; it is an active processing tool that ensures chemical purity by preventing oxidation and maximizes physical density by evacuating gases that would otherwise inhibit pore closure.

Preserving Chemical Integrity

Prevention of High-Temperature Oxidation

High temperatures accelerate chemical reactions between metals and atmospheric gases. Without a vacuum, the heat required for sintering would cause immediate oxidation of the stainless steel powder.

By removing air, the vacuum eliminates oxygen, carbon dioxide, and moisture from the processing chamber. This ensures the material retains its intended chemical composition without forming brittle oxide layers.

Protection of Alloying Elements

Stainless steel relies on specific alloying elements, such as Chromium, to provide corrosion resistance. These elements are often highly reactive (active) and prone to "secondary oxidation" when exposed to heat.

The vacuum environment specifically protects these active elements from reacting with environmental impurities. This preservation is vital for maintaining the alloy's performance characteristics, such as rust resistance and mechanical strength.

Maximizing Material Density

Eliminating Interstitial Gases

Metal powders contain microscopic gaps (interstices) filled with air and volatile impurities. If these gases remain trapped during the pressing and heating process, they create internal voids.

The vacuum state evacuates these gases and volatile impurities before the material creates a solid seal. This allows the powder particles to make physical contact without gas pockets acting as a barrier.

Facilitating Pore Closure

Achieving "near-theoretical density" (a solid block with zero porosity) requires that all internal pores be closed.

By removing the gas from inside the pores, the vacuum removes the internal pressure that would otherwise resist the sintering force. This promotes complete pore closure, leading to a much stronger and denser final product.

Enhancing Diffusion Bonding

Sintering relies on atoms moving across particle boundaries to fuse them together, known as diffusion bonding or "neck growth."

Oxides and impurities on the surface of powder particles act as barriers to this diffusion. Because the vacuum creates an ultra-clean environment, particle surfaces remain metallic and reactive, allowing for faster and stronger bonding between particles.

Understanding the Trade-offs

Process Complexity and Cycle Time

While vacuum sintering yields superior results, it introduces significant complexity compared to atmospheric furnaces.

The equipment requires robust pumping systems to reach high-vacuum levels (e.g., 10^-3 Pa). Furthermore, the processing cycle is often longer because time must be allocated to pump the chamber down to the required vacuum level before heating can begin.

Sensitivity to Vapor Pressure

Operating in a high vacuum at high temperatures can theoretically lead to the vaporization of certain volatile elements within an alloy.

While this is managed through precise temperature control, it requires a strict balance. The operator must ensure the vacuum is strong enough to remove impurities but not so aggressive that it alters the alloy's composition by evaporating desired elements.

Making the Right Choice for Your Goal

While the vacuum hot press offers comprehensive benefits, your specific project goals dictate which aspect of the vacuum is most critical.

- If your primary focus is Corrosion Resistance: The vacuum's ability to prevent the oxidation of Chromium and other active elements is the decisive factor.

- If your primary focus is Mechanical Strength: The vacuum's role in evacuating gases to allow for near-theoretical density and complete pore closure is the key value driver.

The vacuum environment transforms the hot press from a simple heating tool into a precision instrument capable of producing aerospace-grade stainless steel components.

Summary Table:

| Feature | Impact on Sintering | Benefit to Final Product |

|---|---|---|

| Oxygen Removal | Prevents high-temperature oxidation | Maintains chemical purity and corrosion resistance |

| Gas Evacuation | Eliminates internal voids and air pockets | Achieves near-theoretical density and strength |

| Surface Cleaning | Removes oxides from particle surfaces | Enhances diffusion bonding and structural integrity |

| Impurity Volatilization | Removes volatile contaminants | Ensures cleaner alloy composition |

| Controlled Environment | Protects reactive alloying elements | Preserves mechanical properties (e.g., Chromium) |

Elevate Your Material Performance with KINTEK

Precision sintering requires more than just heat—it requires a perfectly controlled environment. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum Hot Press Systems, Muffle, Tube, and CVD furnaces designed to deliver the chemical purity and structural density your aerospace or industrial projects demand.

Whether you need a standard solution or a customizable system tailored to your unique sintering parameters, our team is ready to help you achieve near-theoretical density and superior corrosion resistance.

Ready to optimize your lab's high-temperature processing? Contact us today to discuss your specific needs!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What high-temperature applications do vacuum furnaces serve? Unlock Purity and Precision in Advanced Manufacturing

- What types of metallurgical processes can vacuum furnaces perform? Achieve Purity and Precision in Metal Treatment

- How does argon help control aluminum volatilization in vacuum furnaces? Master Your Smelting Yields

- How are vacuum furnaces used in the preparation of special alloys? Unlock Purity and Performance

- What is the purpose of introducing argon gas into a vacuum furnace during the cooling stage of magnesium vacuum distillation? Ensure Purity and Efficiency

- What are the advantages of using a vacuum heat treatment furnace? Optimize Fe-Mn-Si Alloy Solution Treatment

- What are the benefits of using drop-bottom quench furnaces? Achieve Superior Metallurgical Precision and Rapid Quenching

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control