When process control and metallurgical precision are paramount, a drop-bottom quench furnace offers unparalleled benefits. Its core advantages are extremely rapid and uniform quenching, precise temperature control, and the ability to consistently produce parts with superior mechanical properties, which is why it is essential in demanding industries like aerospace and automotive.

The central challenge in many heat treatments is not just heating the part, but cooling it with extreme speed and uniformity. A drop-bottom furnace is engineered to solve this specific problem by minimizing the transfer time between the heating chamber and the quench tank, thereby maximizing material strength and minimizing distortion.

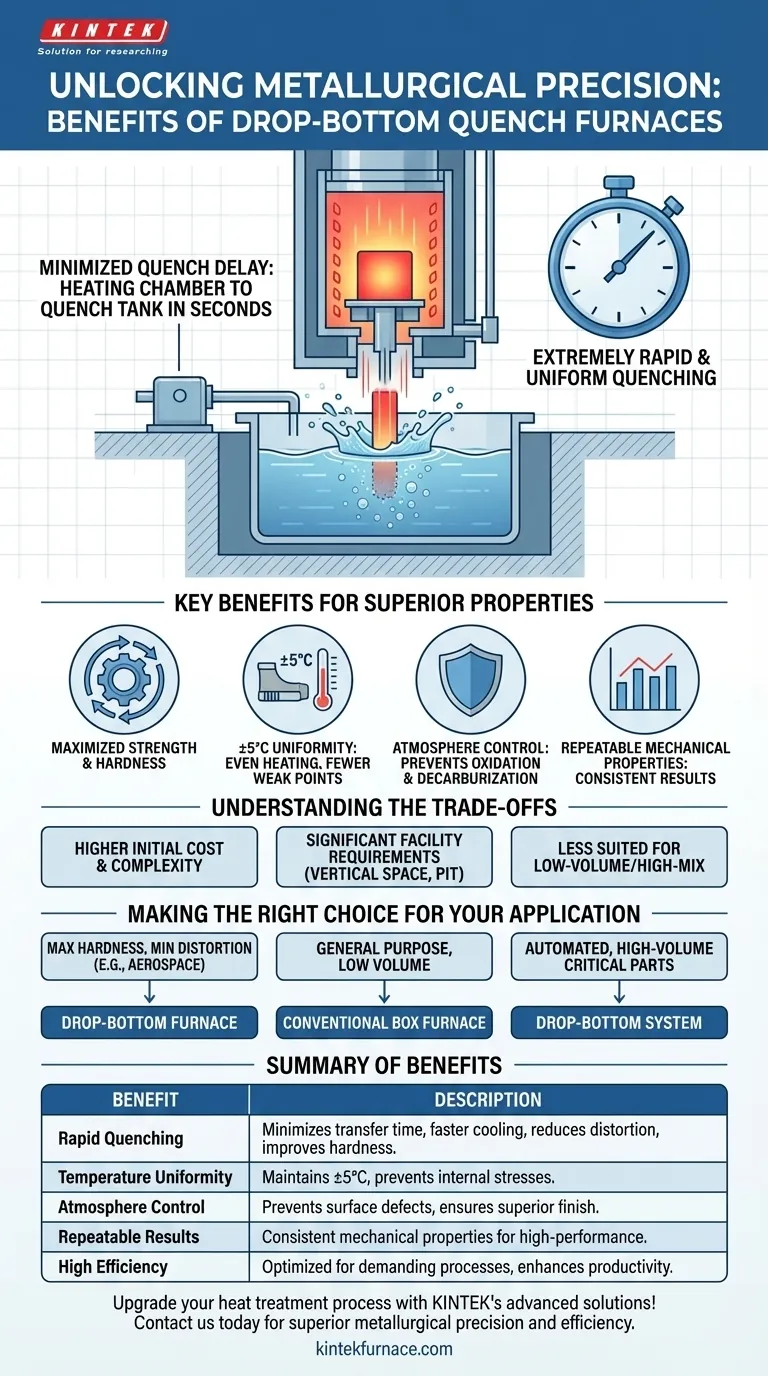

The Core Advantage: Minimizing Quench Delay

The primary benefit of a drop-bottom furnace stems from its unique physical design, which is engineered to eliminate the single biggest variable in quenching: time.

How a Drop-Bottom Furnace Works

A drop-bottom furnace consists of a vertical heating chamber situated directly above a quench tank. The workload is heated to the precise temperature, and once the soaking phase is complete, the entire floor of the furnace opens, dropping the load directly into the liquid quenchant (oil, water, or polymer) below.

This entire transfer process can take as little as a few seconds.

The Impact of Rapid Transfer

This minimal delay between heating and quenching is critical for metallurgical quality. It prevents the premature cooling of the component in open air, which can cause undesirable phase transformations, lead to soft spots, and reduce the final hardness of the material.

By ensuring the part enters the quench medium at its optimal temperature, the furnace guarantees the fastest possible cooling rate, locking in the desired material structure.

Key Benefits for Material Properties

The design of a drop-bottom furnace directly contributes to achieving superior and highly repeatable results, which is why they are specified for critical components.

Unmatched Temperature Uniformity

These furnaces are designed for high thermal efficiency and exceptional temperature uniformity, often within ±5°C. This precision ensures that the entire part, regardless of its geometry, reaches the same temperature, preventing internal stresses and weak points that can arise from uneven heating.

Precision Atmosphere Control

Many drop-bottom furnaces provide tight control over the internal atmosphere. This is crucial for preventing surface defects like oxidation (scaling) and decarburization on steel components, ensuring the final part meets strict surface finish and fatigue life requirements.

Enhanced and Repeatable Mechanical Properties

The combination of uniform heating and ultra-fast quenching delivers exceptional material properties. This process is essential for solution heat treating aluminum alloys to achieve maximum strength or for hardening steel parts to achieve consistent, through-section hardness with minimal distortion.

Understanding the Trade-offs

While powerful, drop-bottom furnaces are specialized equipment. Their advantages come with specific considerations that make them unsuitable for every application.

Higher Initial Cost and Complexity

A drop-bottom furnace is a more complex system than a standard box furnace. The mechanism for the drop-bottom door, the elevator system for the quench tank, and the integrated controls result in a higher capital investment and more sophisticated maintenance needs.

Significant Facility Requirements

Their vertical design requires significant overhead clearance. Furthermore, the quench tank is often situated in a pit below floor level, demanding specific and permanent facility modifications that are more extensive than those for a simple front-loading furnace.

Less Suited for Low-Volume, High-Mix Work

While versatile in the parts they can handle, the setup and operation are geared toward repeatable, high-performance processes. For a job shop that handles a wide variety of small, one-off jobs, a more flexible and less costly batch or box furnace may be a more practical choice.

Making the Right Choice for Your Application

Selecting the right furnace depends entirely on the metallurgical requirements of your components and your production environment.

- If your primary focus is maximum hardness and minimal distortion in sensitive alloys (e.g., aerospace aluminum): A drop-bottom furnace is the superior choice due to its rapid, repeatable, and uniform quench.

- If your primary focus is general-purpose heat treatment for non-critical, low-volume parts: A conventional box furnace offers better cost-effectiveness and greater operational simplicity.

- If your primary focus is automated, high-volume production of strength-critical parts: The integrated design and process control of a drop-bottom system will deliver unmatched consistency and long-term value.

Ultimately, choosing a drop-bottom furnace is a decision to prioritize metallurgical excellence and process repeatability above all else.

Summary Table:

| Benefit | Description |

|---|---|

| Rapid Quenching | Minimizes transfer time to quench tank for faster cooling, reducing distortion and improving hardness. |

| Temperature Uniformity | Maintains ±5°C uniformity for even heating, preventing internal stresses and weak points. |

| Atmosphere Control | Prevents oxidation and decarburization, ensuring superior surface finish and fatigue life. |

| Repeatable Results | Ensures consistent mechanical properties, ideal for high-performance applications. |

| High Efficiency | Optimized for demanding processes, enhancing productivity in critical industries. |

Upgrade your heat treatment process with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-performance drop-bottom quench furnaces tailored for aerospace, automotive, and other demanding industries. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to achieve superior metallurgical precision and efficiency in your operations!

Visual Guide

Related Products

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- How do vacuum furnaces contribute to long-term cost savings? Reduce Costs with Efficiency and Quality

- Why might a vacuum furnace maintain vacuum during cooling? Protect Workpieces from Oxidation and Control Metallurgy

- What role does a vacuum sintering furnace play in the formation of the 'core-rim' structure in Ti(C,N)-FeCr cermets?

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures