In magnesium vacuum distillation, introducing argon gas during the cooling stage serves a critical dual purpose. It dramatically accelerates the cooling of the furnace through convection while simultaneously creating a protective, inert atmosphere that prevents the hot, high-purity magnesium from re-oxidizing and becoming contaminated.

The core challenge after refining magnesium is protecting the final product while it is still hot and highly reactive. Argon gas acts as both a physical cooling medium to improve efficiency and a chemical shield to guarantee the purity achieved during distillation is not lost.

The Dual Role of Argon in the Cooling Phase

After the high-temperature distillation process is complete, the condensed, pure magnesium must be cooled back to room temperature. Introducing argon at this stage solves two distinct problems simultaneously.

Accelerating Cooling via Convection

A vacuum is an excellent insulator, which means heat can only escape the system slowly through radiation. This creates a bottleneck, extending the overall process time significantly.

By backfilling the furnace with argon, you introduce a medium for convective heat transfer. The argon gas circulates within the chamber, carrying heat away from the hot magnesium and furnace walls much more efficiently than radiation alone, thereby shortening the cooling cycle.

Preventing Re-oxidation

Magnesium is a highly reactive metal, especially at the elevated temperatures present immediately after distillation. The final product is exceptionally pure and therefore extremely susceptible to contamination.

As a noble gas, argon is chemically inert; it will not react with the hot magnesium. It displaces any residual reactive gases like oxygen that may remain in the furnace or enter through microscopic leaks, forming a protective blanket over the magnesium and preserving its chemical integrity.

Why a Simple Vacuum Isn't Enough

While the process occurs in a vacuum furnace, relying solely on the vacuum during cooling presents significant risks to both efficiency and product quality.

The Limits of a Perfect Vacuum

Achieving and maintaining a perfect vacuum is practically impossible. There will always be a small quantity of residual gas molecules within the furnace chamber.

The Threat of Outgassing

Internal furnace components, like the crucible and insulation, can adsorb moisture and other gases. A "baking-out" pretreatment is often used to drive these off, but some outgassing can still occur as temperatures change. These released impurities can easily contaminate the magnesium.

The Chemical Nature of Magnesium

The fundamental issue is magnesium's high affinity for oxygen. Without the protective barrier of an inert gas like argon, any stray oxygen molecule that comes into contact with the hot magnesium surface will readily form magnesium oxide, compromising the purity of the final product.

Understanding the Key Considerations

Using argon effectively requires understanding a few critical operational factors. This isn't just about dumping gas into a chamber; it's a controlled part of a high-precision process.

Gas Purity is Crucial

The argon used for backfilling must itself be of high purity. Introducing low-grade argon would be counterproductive, as it would bring contaminants like oxygen and moisture back into the clean environment, defeating the primary purpose of protecting the magnesium.

Controlled Pressure

The amount of argon introduced must be carefully controlled. While a higher pressure can increase the rate of convective cooling, the goal is to create a stable, protective, low-pressure atmosphere. This ensures repeatable conditions for every cycle and prevents uncontrolled interactions.

The Importance of Timing

Argon is introduced after the vacuum distillation phase is complete. Introducing it too early could interfere with the evaporation and transport of magnesium vapor, which relies on a high-vacuum environment to proceed efficiently.

Making the Right Choice for Your Goal

The use of argon is a strategic decision that directly impacts the outcome of the refining process. By understanding its functions, you can optimize for your specific priorities.

- If your primary focus is throughput and efficiency: Argon backfilling is essential for shortening cycle times by enabling rapid, convective cooling.

- If your primary focus is maximum product purity: Using high-purity argon is non-negotiable to create an inert shield that prevents re-oxidation of the highly reactive, hot magnesium.

- If your primary focus is process reliability: A controlled argon atmosphere isolates the final product from minor vacuum fluctuations or leaks, ensuring consistent, high-quality results.

Ultimately, argon is a critical tool that transforms the cooling phase from a passive, slow, and risky waiting period into an active, efficient, and protective final step in producing high-purity magnesium.

Summary Table:

| Purpose | Key Benefit | Why It Matters |

|---|---|---|

| Accelerate Cooling | Enables convective heat transfer | Reduces cycle time and increases throughput |

| Prevent Re-oxidation | Creates an inert, protective atmosphere | Preserves the high purity of the final magnesium product |

| Enhance Process Reliability | Shields against minor leaks and outgassing | Ensures consistent, high-quality results batch after batch |

Achieve Superior Magnesium Refining with KINTEK's Advanced Vacuum Furnaces

Producing high-purity magnesium requires precise control over every stage of the vacuum distillation process. At KINTEK, we engineer our Muffle, Tube, Rotary, and Vacuum furnaces with the expertise to handle reactive metals like magnesium. Our systems are designed to integrate critical steps like controlled argon backfilling, ensuring your final product meets the highest standards of purity and your operation achieves maximum efficiency.

Backed by expert R&D and manufacturing, KINTEK offers fully customizable lab high-temperature furnace solutions, including CVD systems, to meet your unique production needs.

Ready to optimize your magnesium distillation process? Contact our experts today to discuss how our reliable and efficient furnace technology can benefit your lab or production facility.

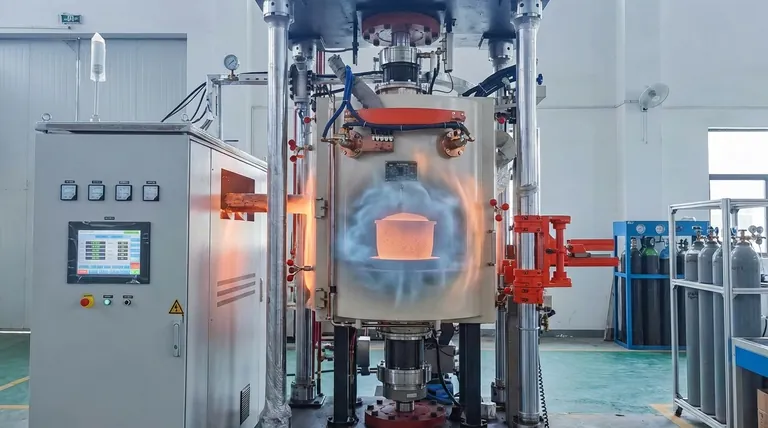

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control