At its core, vacuum carburizing ensures stable quality by replacing the unpredictable variables of atmospheric heat treatment with precise, digitally managed parameters in an oxygen-free environment. This method gives engineers unparalleled control over the entire process, from heating to quenching, resulting in a highly repeatable and superior metallurgical outcome.

The fundamental reason for the stability of vacuum carburizing is its ability to eliminate environmental variables. By removing oxygen and precisely controlling the introduction of carbon, the process becomes a predictable, repeatable series of digital inputs rather than a delicate chemical balancing act.

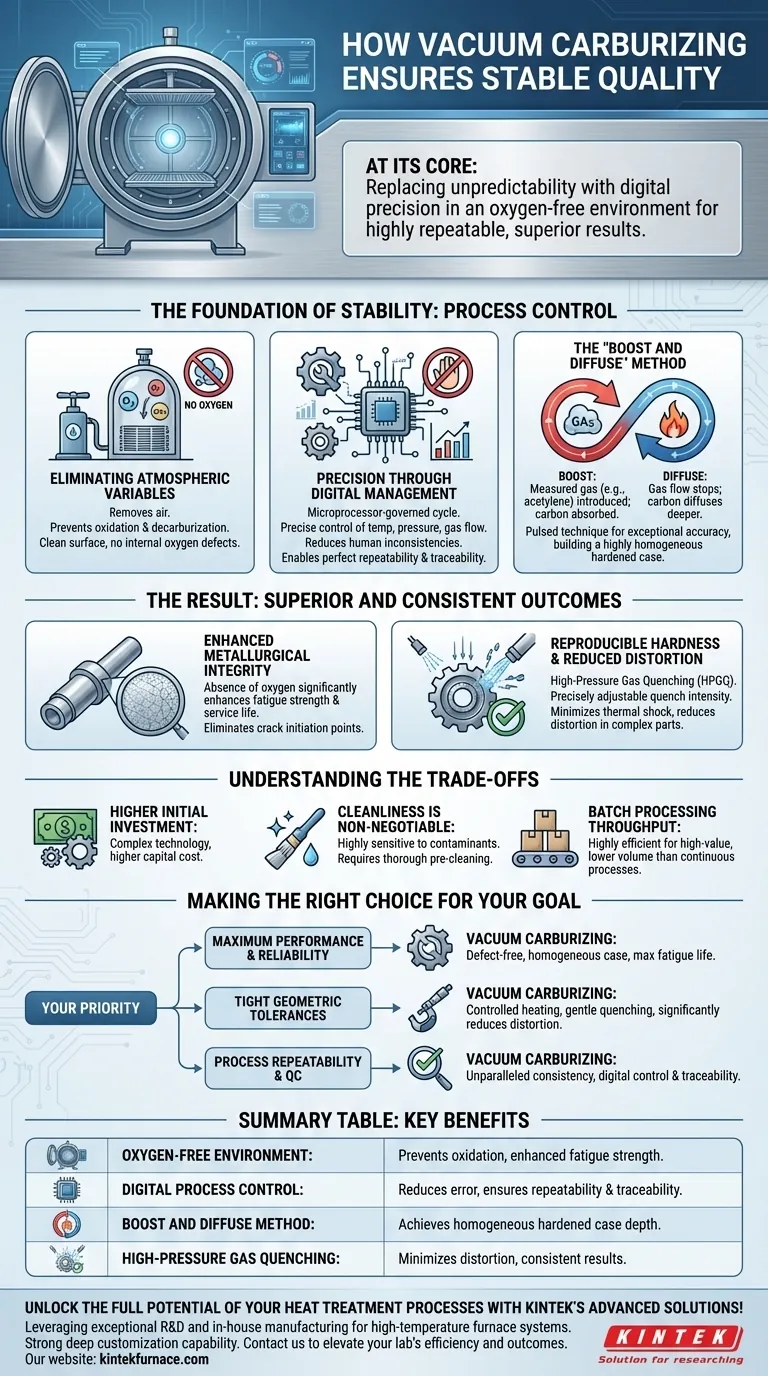

The Foundation of Stability: Process Control

The consistency of vacuum carburizing, also known as Low Pressure Carburizing (LPC), is not accidental. It is the direct result of a fundamentally different approach to the heat treatment process.

Eliminating Atmospheric Variables

In traditional methods, the furnace atmosphere is a complex mixture that includes oxygen, which can cause unwanted reactions. Vacuum carburizing begins by removing the air from the chamber.

This vacuum environment completely prevents oxidation and decarburization on the part's surface. This means the final product maintains its original metal color and is free from the internal oxygen defects (often called "black structure") that can compromise part integrity.

Precision Through Digital Management

The entire cycle is governed by a microprocessor. Critical parameters like temperature, pressure, and gas flow timings are not just monitored but actively controlled with digital precision.

This reduces human-factor inconsistencies and ensures that every batch is processed under the exact same conditions. The detailed data logging allows for perfect repeatability and traceability, which is crucial for quality assurance standards like CQI-9.

The "Boost and Diffuse" Method

Instead of maintaining a constant carbon-rich atmosphere, vacuum carburizing uses a pulsed technique. The process alternates between two stages:

- Boost: A small, measured amount of carburizing gas (typically acetylene) is introduced into the hot chamber. The gas breaks down, and its carbon atoms are absorbed by the steel's surface.

- Diffuse: The gas flow is stopped, and the absorbed carbon is allowed to diffuse deeper into the part's surface, driven by heat and time.

This cycle is repeated multiple times. By precisely controlling the duration of each boost and diffuse step, engineers can build a case depth profile with exceptional accuracy and create a highly homogeneous hardened case.

The Result: Superior and Consistent Outcomes

This level of control directly translates to measurable improvements in the final workpiece, creating a new standard for quality and reliability.

Enhanced Metallurgical Integrity

The absence of oxygen not only keeps the parts clean but also significantly enhances the fatigue strength and service life of the component. Eliminating surface and sub-surface oxidation removes potential initiation points for cracks under cyclic loading.

Reproducible Hardness and Reduced Distortion

After carburizing, parts are quenched. Many vacuum furnaces use high-pressure gas quenching (HPGQ) with nitrogen or helium.

The intensity of this quench can be precisely adjusted by controlling the gas pressure and velocity. This provides consistent and reproducible quenching results and, critically, minimizes the thermal shock that causes distortion in complex or thin-walled parts.

Understanding the Trade-offs

While offering superior quality, vacuum carburizing is not a universal solution. Understanding its context is key to making an informed decision.

Higher Initial Investment

Vacuum furnace technology is more complex and has a higher capital cost than traditional atmospheric furnace equipment. The precision and control come at a price.

Cleanliness is Non-Negotiable

The process is highly sensitive to contaminants. Parts must be thoroughly cleaned before entering the furnace, as any residual oils or fluids can vaporize and interfere with the vacuum and carburizing process.

Batch Processing Throughput

Vacuum carburizing is inherently a batch process. While highly efficient for high-value components, it may not match the throughput of some large, continuous atmospheric furnaces used for mass-producing lower-spec parts.

Making the Right Choice for Your Goal

The decision to use vacuum carburizing should be driven by the specific requirements of your component and production goals.

- If your primary focus is maximum performance and reliability: Vacuum carburizing is the ideal choice for its ability to create a defect-free surface and a homogeneous case, maximizing fatigue life.

- If your primary focus is maintaining tight geometric tolerances: The controlled, uniform heating and gentle gas quenching process significantly reduces distortion compared to traditional methods.

- If your primary focus is process repeatability and quality control: The digital control and data logging inherent to the process provide unparalleled consistency and traceability for critical applications.

By removing ambiguity and environmental interference, vacuum carburizing transforms heat treatment from a craft into a precise, data-driven science.

Summary Table:

| Key Aspect | Benefit |

|---|---|

| Oxygen-Free Environment | Prevents oxidation and decarburization, ensuring clean surfaces and enhanced fatigue strength |

| Digital Process Control | Reduces human error, enables precise parameter management, and ensures repeatability and traceability |

| Boost and Diffuse Method | Achieves homogeneous hardened case depth with accurate carbon absorption and diffusion |

| High-Pressure Gas Quenching | Minimizes distortion and provides consistent, reproducible quenching results |

Unlock the full potential of your heat treatment processes with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise alignment with your unique experimental needs, delivering enhanced metallurgical integrity and process stability. Ready to elevate your lab's efficiency and outcomes? Contact us today to discuss how we can support your goals!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today