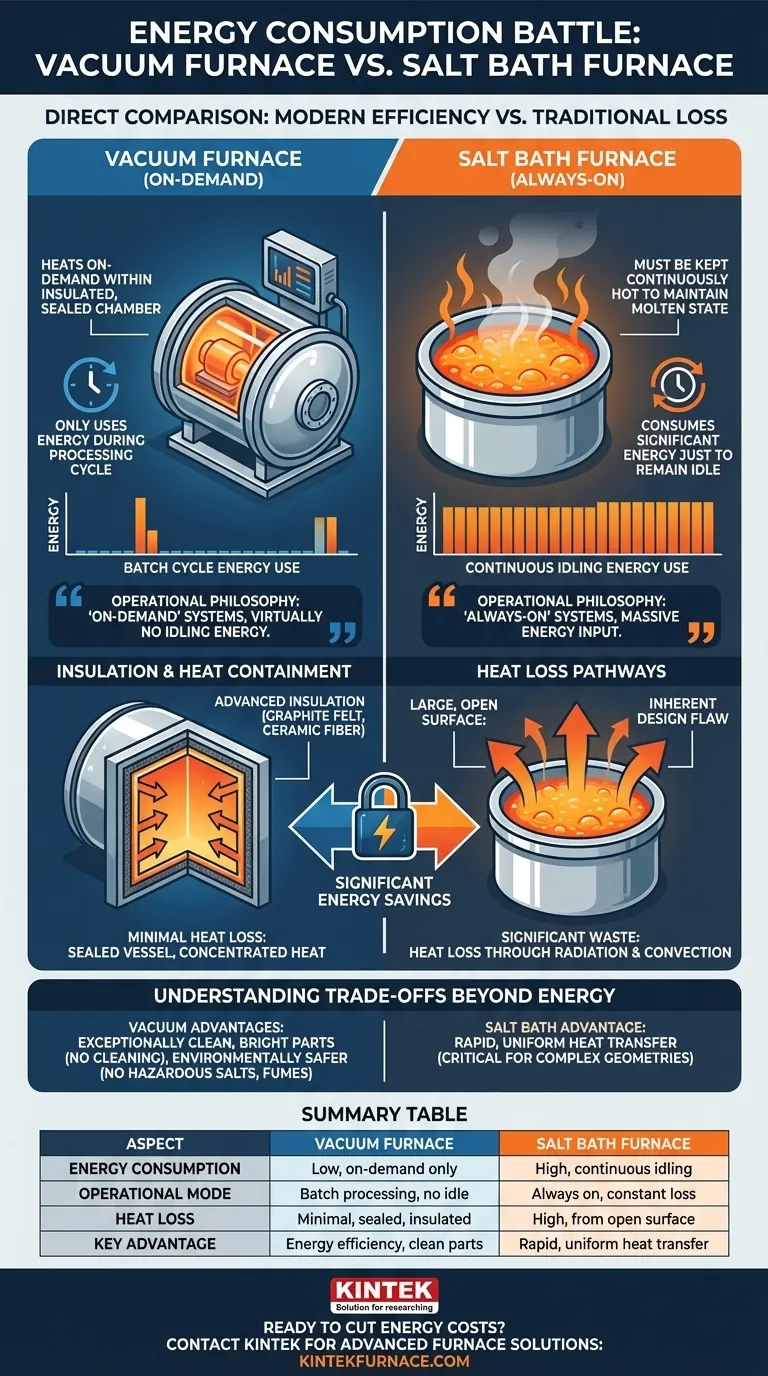

In a direct comparison, a modern vacuum furnace is significantly more energy-efficient than a traditional salt bath furnace. The core reason lies in its design and operational principle: a vacuum furnace heats on-demand within a highly insulated, sealed chamber, whereas a salt bath must be kept continuously hot to maintain the molten state of the salt, leading to constant energy loss.

The fundamental difference in energy consumption comes down to operational philosophy. Vacuum furnaces are "on-demand" systems that use energy only during a processing cycle, while salt baths are "always-on" systems that consume significant energy just to remain idle.

Understanding the Core Difference in Operation

To grasp the energy disparity, you must look beyond the furnaces themselves and focus on how they are used day-to-day. The operational mode is the single biggest factor driving the difference in energy bills.

The "Always On" Nature of Salt Bath Furnaces

A salt bath furnace works by immersing parts in a pot of molten salt heated to a specific temperature. To be ready for production, this large volume of salt must be kept in a liquid state.

This requires a massive and continuous energy input, known as idling energy, even when no parts are being processed. The large, open surface of the molten salt constantly loses heat to the surrounding environment through radiation and convection, representing a significant and unavoidable energy waste.

The "On-Demand" Principle of Vacuum Furnaces

A vacuum furnace operates in discrete batches. The chamber is loaded with parts at room temperature, sealed, and then a vacuum is created. Only then does the heating cycle begin.

Because the furnace only consumes significant power during an active cycle, there is virtually no idling energy consumption. When the furnace is not running a cycle, its energy use is negligible.

A Deeper Look at Efficiency Factors

While the operational mode is primary, the physical design of each furnace type further widens the efficiency gap.

Insulation and Heat Containment

Modern vacuum furnaces are engineered for maximum thermal efficiency. They use multi-layered insulation packages, often combining graphite felt, ceramic fiber, and reflective metallic heat shields.

This advanced insulation ensures that the heat generated is concentrated directly on the workload and is not lost to the furnace structure or the ambient air.

Heat Loss Pathways

The primary heat loss pathway in a salt bath is the large, open surface of the salt pot. This is an inherent and unavoidable design flaw from an energy perspective.

Conversely, a vacuum furnace is a tightly sealed vessel. Once the door is closed, the only significant heat loss is through the insulated walls, which is minimal by design. The vacuum itself also eliminates heat loss through convection, further improving efficiency.

Understanding the Trade-offs Beyond Energy

Choosing a furnace is not solely about energy consumption. You must weigh the efficiency gains against other critical process factors.

Heat Transfer Rate

A key advantage of a salt bath is its extremely rapid and uniform heat transfer. The direct contact between the liquid salt and the part's surface heats it quickly and evenly. This can be critical for complex geometries or to minimize distortion.

Vacuum furnace heating is primarily driven by radiation, which is generally slower. While modern high-pressure gas quenching can achieve rapid cooling, the heating portion of the cycle is typically longer than in a salt bath.

Process Quality and Part Cleanliness

Vacuum furnaces produce exceptionally clean, bright parts that require no post-process cleaning. Since the process occurs in a controlled atmosphere free of oxygen, there is no oxidation or surface decarburization.

Parts from a salt bath must be thoroughly cleaned to remove residual salt, which can be corrosive. This adds an extra, often messy, step to the production workflow.

Environmental and Safety Concerns

Operating a salt bath involves significant safety and environmental considerations. The salts can be hazardous, disposal is a regulated process, and the fumes require proper ventilation and extraction systems.

Vacuum processing is an inherently cleaner and safer technology. It eliminates the need for hazardous salts, costly disposal, and complex fume management systems.

Making the Right Choice for Your Goal

The decision between a vacuum and salt bath furnace depends entirely on your specific operational priorities and long-term goals.

- If your primary focus is minimizing operational costs and environmental impact: A vacuum furnace is the clear choice due to its superior on-demand energy efficiency and cleaner process.

- If your primary focus is the absolute fastest heating rate for distortion-sensitive parts: A salt bath's heat transfer characteristics may still be relevant, but you must accept the high standby energy costs and safety overhead.

Ultimately, evaluating the total cost of ownership—including energy, maintenance, labor, and compliance—will empower you to select the technology that best aligns with your strategic objectives.

Summary Table:

| Aspect | Vacuum Furnace | Salt Bath Furnace |

|---|---|---|

| Energy Consumption | Low, on-demand only | High, continuous idling |

| Operational Mode | Batch processing, no idle energy | Always on, constant heat loss |

| Heat Loss | Minimal, sealed and insulated | High, from open salt surface |

| Key Advantage | Energy efficiency, clean parts | Rapid, uniform heat transfer |

Ready to cut your energy costs and enhance process efficiency? KINTEK specializes in advanced high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. With our strong R&D and in-house manufacturing, we offer deep customization to meet your unique lab needs. Contact us today to discuss how our tailored solutions can benefit your operations!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- What is the role of vacuum pumps in a vacuum heat treatment furnace? Unlock Superior Metallurgy with Controlled Environments

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density