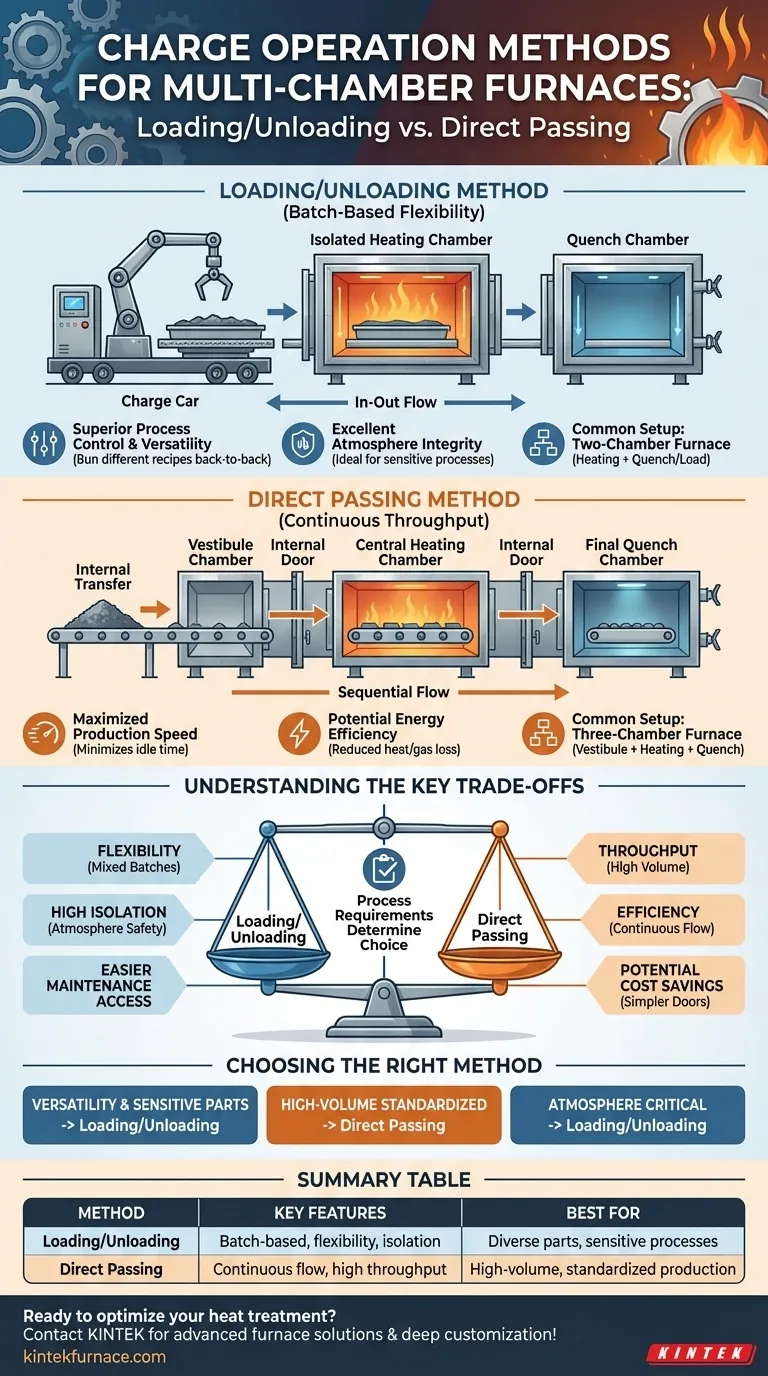

In industrial heat treatment, the two fundamental charge operation methods for multi-chamber furnaces are the loading/unloading method and the direct passing method. These designs dictate how material moves between heating, processing, and quenching zones, forming the basis of the furnace's operational philosophy and directly impacting throughput, flexibility, and process control.

The choice between a loading/unloading method and a direct passing method is a foundational decision between process flexibility and maximum throughput. Loading/unloading offers superior batch-based control and adaptability, while direct passing is engineered for high-volume, continuous production.

The Loading/Unloading Method: Batch-Based Flexibility

This method, often called an "in-out" system, treats each chamber as a distinct, isolated processing station.

How It Works

A load of material is moved into a chamber by an external mechanism, often called a charge car or manipulator. The chamber door is sealed, the process (e.g., heating) is run, and the door is opened again. The same external manipulator then removes the load and transfers it to the next chamber (e.g., a quench tank or cooling station).

Key Advantage: Process Control and Versatility

Because each load is handled independently, the loading/unloading method offers exceptional flexibility. You can easily run different parts with different time, temperature, and atmosphere "recipes" back-to-back without compromising either process.

Key Advantage: Superior Chamber Isolation

The chambers are fully separate. This provides excellent atmospheric integrity, preventing contaminants like quench oil vapor from entering the high-temperature heating chamber. This is critical for sensitive processes like carburizing or nitriding where atmosphere purity is paramount.

Common Configuration: The Two-Chamber Furnace

A classic example is a two-chamber furnace consisting of a sealed heating chamber and an attached loading/unloading/quench chamber. The charge car loads the material into the heating chamber, retrieves it after the cycle, and lowers it into the quench tank, all within the second chamber.

The Direct Passing Method: Continuous Throughput

This method operates more like an assembly line, where the material moves sequentially from one zone directly into the next through the furnace's interior.

How It Works

Material is loaded into the first chamber or vestibule. After its process step, an internal door opens, and an internal transfer mechanism pushes or pulls the load directly into the next adjacent chamber. This continues until the load exits the final chamber.

Key Advantage: Maximized Production Speed

This method minimizes idle time. As one load moves into the second chamber, a new load can immediately enter the first. This continuous flow is ideal for high-volume production of standardized parts where the process recipe rarely changes.

Key Advantage: Potential Energy Efficiency

Because the material moves through smaller, internal openings, there can be less heat and protective atmosphere loss compared to opening a large main door for an external charge car. This can lead to energy and gas consumption savings in high-utilization scenarios.

Common Configuration: The Three-Chamber Furnace

A typical direct passing furnace has three chambers: a loading/purging vestibule, a central heating chamber, and a final quench or cooling chamber. This layout facilitates a smooth, uninterrupted flow of material from start to finish.

Understanding the Trade-offs

Neither method is universally superior; the correct choice depends entirely on the application's specific requirements.

Throughput vs. Flexibility

This is the central trade-off. Direct passing prioritizes throughput for standardized parts. Loading/unloading prioritizes flexibility for a mix of different parts and processes.

Atmosphere Integrity

The loading/unloading method provides the highest level of atmosphere isolation between chambers. In a direct passing system, there is always a risk of some atmosphere "drag-out" when the internal door opens, which could compromise highly sensitive processes.

Capital Cost and Footprint

A simple two-chamber loading/unloading system may have a lower initial cost and smaller footprint. However, complex, multi-station loading/unloading systems with sophisticated charge cars can become larger and more expensive than their direct passing counterparts.

Maintenance and Access

External charge cars in a loading/unloading system are typically easier to access for maintenance. Internal transfer mechanisms in a direct passing furnace can be more difficult to reach, potentially leading to more complex and time-consuming repairs inside the furnace.

Choosing the Right Method for Your Process

Your operational goals are the primary driver for selecting a charge handling method. Consider the following to make a clear decision.

- If your primary focus is process versatility and handling diverse parts: Choose the loading/unloading method for its superior batch-level control and atmospheric isolation.

- If your primary focus is high-volume, standardized production: Select the direct passing method to maximize throughput and operational efficiency.

- If your process is extremely sensitive to atmospheric contamination: The superior chamber isolation of the loading/unloading method makes it the safer, more reliable choice.

By understanding this core trade-off between batch flexibility and continuous throughput, you can align your furnace architecture directly with your production strategy.

Summary Table:

| Method | Key Features | Best For |

|---|---|---|

| Loading/Unloading | Batch-based, high flexibility, superior atmosphere isolation | Diverse parts, sensitive processes like carburizing |

| Direct Passing | Continuous flow, high throughput, potential energy savings | High-volume, standardized production |

Ready to optimize your heat treatment with the right furnace method? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how we can enhance your process efficiency and throughput!

Visual Guide

Related Products

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the use of nitrogen in furnace? Prevent Oxidation for Superior Heat Treatment

- What are the two main types of atmosphere furnaces and their characteristics? Choose the Right Furnace for Your Lab

- How does inert atmosphere heat treating benefit aluminum? Prevent Oxide Buildup for Superior Results

- What is the main purpose of heat treatment? Transform Metal Properties for Superior Performance

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance