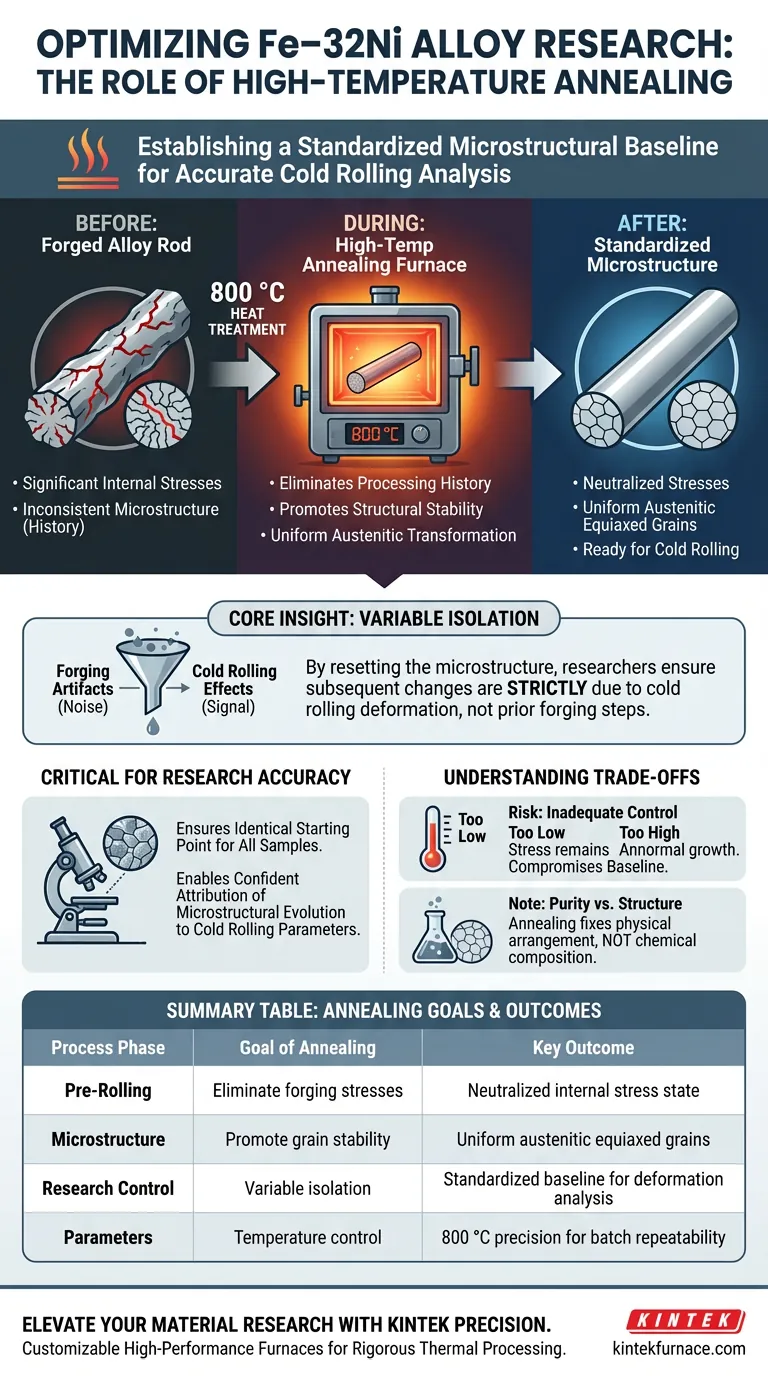

The primary function of using a high-temperature annealing furnace for Fe–32Ni alloys prior to cold rolling is to establish a standardized microstructural baseline. By heating forged alloy rods to 800 °C, the process eliminates internal stresses accumulated during forging and promotes the formation of a stable, austenitic equiaxed grain structure.

Core Insight: The value of this heat treatment lies in variable isolation. By resetting the material’s microstructure to a uniform state, researchers ensure that any changes observed later are solely the result of the cold rolling deformation, rather than artifacts of the previous forging process.

The Mechanics of the Heat Treatment

Eliminating Processing History

Before cold rolling, Fe–32Ni alloy rods typically undergo forging, a process that introduces significant internal stresses.

If left untreated, these residual stresses can cause unpredictable behavior during subsequent processing. High-temperature annealing effectively neutralizes these stresses, returning the material to a neutral state.

Achieving Structural Stability

The furnace acts as a precision environment to stabilize the alloy's internal architecture.

Holding the temperature at 800 °C allows the microstructure to transform. The goal is to achieve a uniform austenitic equiaxed grain structure, which is chemically and mechanically homogeneous.

The Critical Role in Research Accuracy

Establishing a Standardized Initial State

In materials science research, the starting condition of the sample is as critical as the experiment itself.

Without this specific annealing step, the "starting point" for every sample would vary based on inconsistencies in the forging process. This treatment ensures every rod begins the cold rolling phase with identical properties.

Enabling Accurate Deformation Analysis

The ultimate goal of this preparation is to study how cold rolling deformation impacts microstructural evolution.

By guaranteeing a standard initial state, researchers can confidently attribute any microstructural changes—such as grain elongation or texture development—strictly to the cold rolling parameters. This eliminates the "noise" of pre-existing defects or stresses.

Understanding the Trade-offs

The Risk of Inadequate Control

While the target is 800 °C, deviations in temperature or time can compromise the baseline.

Insufficient heating may fail to fully relieve forging stresses, leading to skewed data in the cold rolling phase. Conversely, excessive temperatures could lead to abnormal grain growth, altering the material's mechanical response before testing begins.

Balancing Purity and Structure

It is important to note that while annealing fixes structure, it does not fix composition.

Compositional purity (such as low carbon content) is determined earlier during vacuum induction melting. Annealing strictly addresses the physical arrangement of grains and stress, not the chemical makeup established during the melt.

Ensuring Data Integrity in Material Processing

To maximize the reliability of your Fe–32Ni alloy research, specific processing goals require strict adherence to thermal baselines.

- If your primary focus is fundamental research: Prioritize the standardized initial state to ensure that all microstructural data correlates directly to your cold rolling inputs.

- If your primary focus is process repeatability: strictly monitor the 800 °C temperature uniformity to prevent batch-to-batch variations in the austenitic structure.

Success in characterizing Fe–32Ni alloys depends on rigorous control of the starting microstructure to isolate the variables you intend to study.

Summary Table:

| Process Phase | Goal of Annealing | Key Outcome |

|---|---|---|

| Pre-Rolling | Eliminate forging stresses | Neutralized internal stress state |

| Microstructure | Promote grain stability | Uniform austenitic equiaxed grains |

| Research Control | Variable isolation | Standardized baseline for deformation analysis |

| Parameters | Temperature control | 800 °C precision for batch repeatability |

Elevate Your Material Research with KINTEK Precision

To achieve reliable data in Fe–32Ni alloy studies, microstructural integrity is non-negotiable. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet the most rigorous thermal processing requirements.

Our lab high-temperature furnaces are fully customizable to your unique research needs, ensuring the temperature uniformity and stability required for perfect austenitic transformation. Ready to standardize your heat treatment process? Contact us today to consult with our specialists and find the ideal solution for your laboratory.

Visual Guide

References

- Dongyun Sun, Fucheng Zhang. Effect of Cold Rolling and Cryogenic Treatment on the Microstructure and Mechanical Properties of Fe–32Ni Alloy. DOI: 10.3390/met14020174

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the function of a high-pressure stainless steel autoclave in hydrothermal carbonization? Unlock Superior Carbon

- Why is it necessary to treat porous carbon samples in a vacuum drying oven at 90 °C before electrode coating?

- What role does a vacuum dryer play in the chemical modification of supraparticles? Master Vapor-Phase Hydrophobization

- Why is a vacuum drying oven necessary for M-S-H hydration analysis? Ensure Structural Integrity & Data Accuracy

- What does the vacuum system of a vacuum furnace consist of? Essential Components for Clean Heat Processing

- What are the two main types of vacuum furnace chillers? Choose the Best for Your Lab's Efficiency

- What maintenance is required for vacuum furnace heating elements? Ensure Reliability and Prevent Costly Downtime

- How does a vacuum furnace improve the mechanical properties of workpieces? Enhance Strength and Durability