By creating a pristine, controlled environment, a vacuum furnace improves the mechanical properties of a workpiece by fundamentally changing how heat is applied. This process removes reactive atmospheric gases, preventing surface degradation like oxidation and decarburization. The result is a component with enhanced hardness, superior strength, and a clean surface finish, free from the defects common in conventional heat treatment.

The core advantage of a vacuum furnace is not just the heat, but the absence of air. By removing reactive gases, it allows the heat treatment process to achieve the material's true potential, resulting in superior, more predictable, and cleaner metallurgical outcomes.

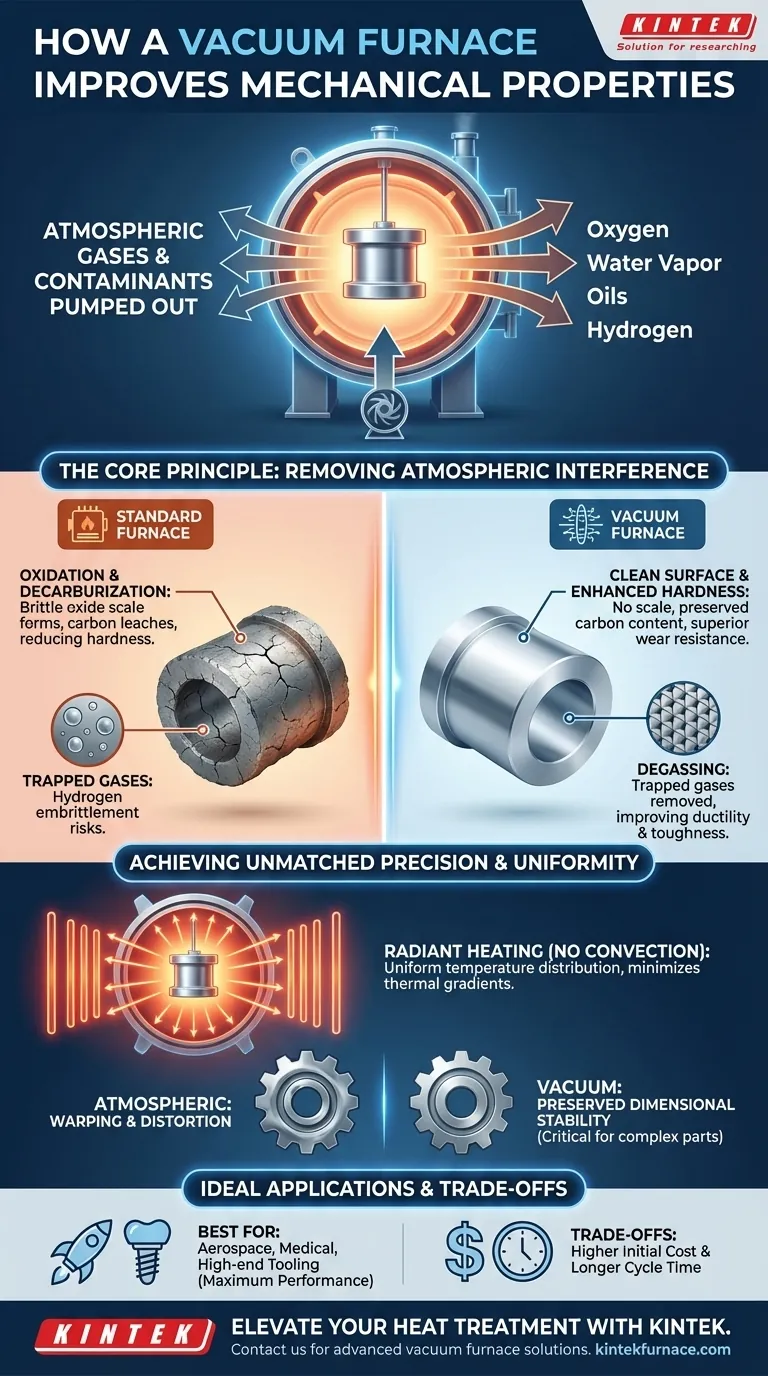

The Core Principle: Removing Atmospheric Interference

At its heart, a vacuum furnace is designed to eliminate the variables that compromise heat treatment. The primary variable is the atmosphere itself, which contains oxygen, water vapor, and other elements that react negatively with hot metal surfaces.

Preventing Oxidation and Decarburization

When steel is heated in the presence of oxygen, a brittle layer of oxide scale forms on the surface. This scale can flake off, ruin the surface finish, and act as a stress concentration point, promoting cracks and reducing fatigue life.

Similarly, the carbon in steel can react with oxygen at high temperatures, a process called decarburization. This leaches carbon from the surface, creating a soft outer layer that compromises the workpiece's hardness and wear resistance. A vacuum environment completely prevents both of these destructive reactions.

Eliminating Surface Contaminants

The vacuum actively helps clean the workpiece. Residual oils, cleaning fluids, and other contaminants on the part's surface will vaporize in the low-pressure environment and be pumped out of the chamber. This results in an exceptionally clean, bright part ready for use or subsequent processing without needing aggressive post-treatment cleaning.

The Benefit of Degassing

Metals can contain dissolved gases, such as hydrogen, which can lead to a dangerous phenomenon called hydrogen embrittlement. This internal defect significantly reduces the material's ductility and toughness. A vacuum furnace pulls these trapped gases out of the metal, improving its internal integrity and resistance to failure.

Achieving Unmatched Precision and Uniformity

Beyond creating a clean environment, the physics of a vacuum fundamentally alters how heat is transferred, leading to greater control over the final product.

The Impact of Convection-Free Heating

In a standard atmospheric furnace, heat is transferred through convection (the movement of hot air). This can lead to uneven heating, as some areas of the part are exposed to hotter air currents than others.

In a vacuum, there is no air to move, so heat is transferred almost exclusively through radiation. This radiant energy heats all line-of-sight surfaces simultaneously and evenly, minimizing thermal gradients across the part. This uniform heating is critical for reducing warping and distortion.

Preserving Dimensional Stability

The reduction of thermal stress is essential for components with complex geometries or tight tolerances, such as gears, bearings, and cutting tools. By heating and cooling the part more uniformly, a vacuum furnace preserves its intended shape, minimizing the need for costly and difficult post-treatment machining.

Understanding the Trade-offs

While technologically superior for many applications, vacuum furnaces are not a universal solution. Understanding their limitations is key to making an informed decision.

Cycle Time and Throughput

Creating a deep vacuum and then backfilling with inert gas for quenching can take longer than simply moving parts through an atmospheric furnace. For high-volume, low-margin parts, this can make vacuum processing less economical.

Initial Cost and Complexity

Vacuum furnaces are sophisticated machines that represent a significant capital investment. They also require more specialized knowledge for operation and maintenance compared to simpler atmospheric furnaces.

Material and Process Suitability

The benefits of a vacuum environment are most pronounced for high-performance alloys, tool steels, and materials where surface integrity is paramount. For simple, low-carbon steels undergoing basic annealing, the added cost may not be justifiable.

Making the Right Choice for Your Application

The decision to use a vacuum furnace should be driven by the specific technical and commercial requirements of your component.

- If your primary focus is maximum performance and reliability: For aerospace, medical, or high-end tooling applications, the clean, defect-free, and repeatable results from a vacuum furnace are essential.

- If your primary focus is dimensional stability: For complex parts like injection molds or precision gears where minimizing distortion is critical, the uniform radiant heating of a vacuum furnace is the superior choice.

- If your primary focus is cost-effective hardening of simple parts: For less critical components where a small amount of surface oxidation is acceptable, a traditional atmospheric furnace often provides a more economical solution.

Ultimately, understanding these principles allows you to select heat treatment as a precise engineering tool, not just a final manufacturing step.

Summary Table:

| Key Benefit | Description |

|---|---|

| Prevents Oxidation | Eliminates surface scale and brittleness by removing oxygen. |

| Prevents Decarburization | Stops carbon loss, maintaining hardness and wear resistance. |

| Removes Contaminants | Vaporizes oils and residues for a clean, bright finish. |

| Degassing | Extracts trapped gases like hydrogen to prevent embrittlement. |

| Uniform Heating | Uses radiation for even temperature distribution, reducing warping. |

| Dimensional Stability | Minimizes distortion in complex parts like gears and tools. |

Ready to elevate your heat treatment process? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs. Whether you're in aerospace, medical, or tooling, our vacuum furnaces deliver superior mechanical properties, enhanced durability, and cleaner outcomes. Contact us today to discuss how we can optimize your lab's performance!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties