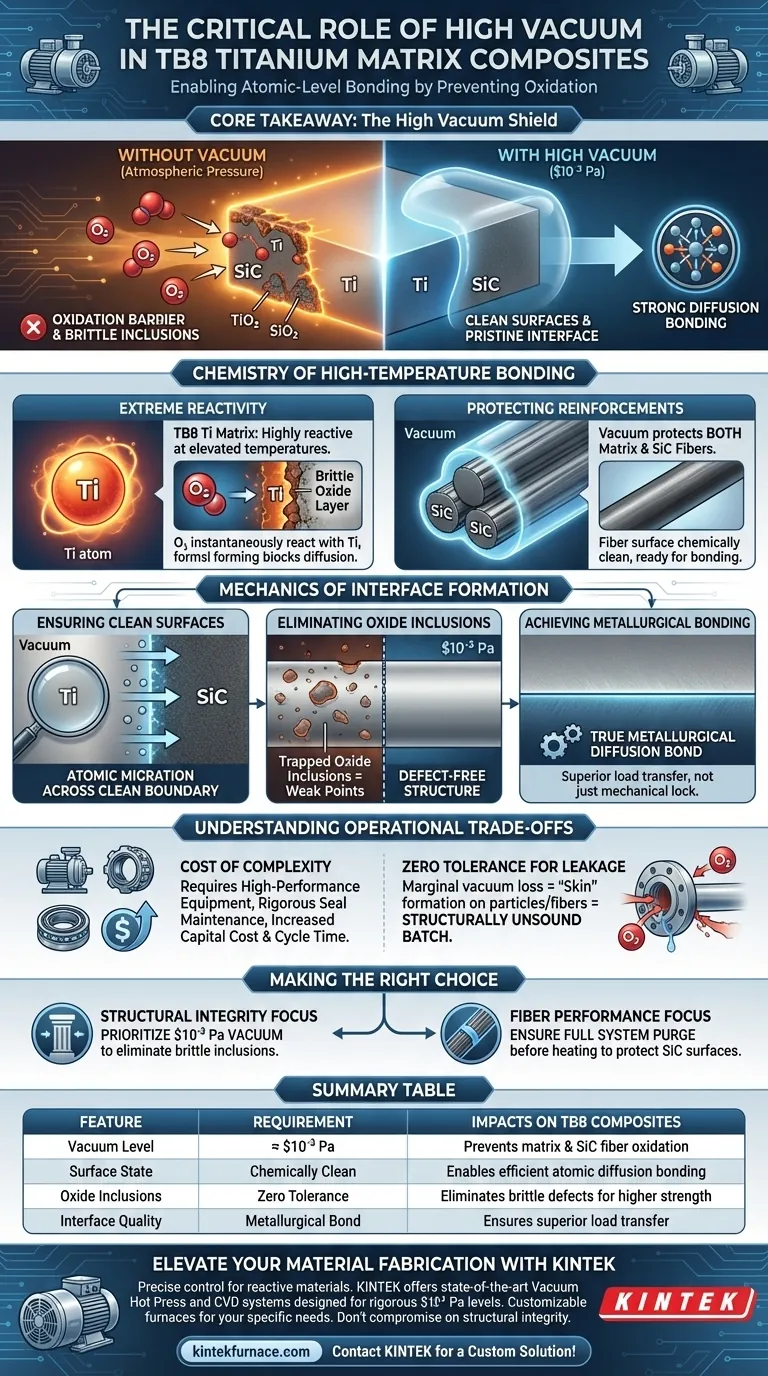

The high vacuum environment is the critical enabler for TB8 titanium matrix composites due to the alloy's extreme chemical activity at elevated temperatures. Specifically, a vacuum level of approximately $10^{-3}$ Pa is required to prevent the rapid oxidation of both the titanium matrix and the reinforcing SiC fibers, ensuring that diffusion bonding can occur on chemically clean surfaces.

Core Takeaway

Titanium alloys possess a high affinity for oxygen, which creates brittle oxide layers that block atomic diffusion. A high vacuum environment removes this barrier, preventing oxide inclusions and ensuring the pristine interfacial contact necessary for high-strength diffusion bonding.

The Chemistry of High-Temperature Bonding

Extreme Chemical Reactivity

At the high temperatures required for hot pressing, the TB8 titanium alloy matrix transitions from a stable state to one of high chemical activity.

Without a vacuum, the matrix reacts instantaneously with trace oxygen. This reaction fundamentally alters the material properties before consolidation even begins.

Protection of Reinforcements

The vacuum environment serves a dual purpose: it protects not only the matrix but also the silicon carbide (SiC) fibers.

If the fibers oxidize, their surface chemistry changes, degrading their intrinsic strength and preventing them from bonding effectively with the titanium matrix.

The Mechanics of Interface Formation

Ensuring Clean Surfaces

The primary goal of the vacuum hot press in this application is to maintain "clean surfaces."

Diffusion bonding relies on the migration of atoms across the boundary between the matrix and the fiber. This process cannot occur if an oxide film sits between the two materials.

Eliminating Oxide Inclusions

Any oxygen present during the pressing stage does not simply disappear; it becomes trapped within the material as oxide inclusions.

A high vacuum environment ($10^{-3}$ Pa) effectively prevents these inclusions from forming. This results in a composite structure free of brittle defects that would otherwise compromise mechanical performance.

Achieving Excellent Interfacial Bonding

The ultimate success of a metal matrix composite depends on the strength of the interface between the metal and the reinforcement.

By preventing oxidation, the vacuum ensures that the bond formed is a true metallurgical diffusion bond, rather than a weak mechanical lock disrupted by oxide layers.

Understanding the Operational Trade-offs

The Cost of Complexity

Achieving and maintaining a vacuum of $10^{-3}$ Pa increases the complexity of the manufacturing equipment.

This requirement necessitates high-performance vacuum pumps and rigorous seal maintenance, which increases both the capital cost of the furnace and the operational cycle time compared to non-vacuum sintering methods.

Zero Tolerance for Leakage

The high reactivity of TB8 means the process has virtually zero tolerance for system leaks.

Even a marginal loss of vacuum pressure can introduce enough oxygen to form a "skin" on the titanium particles or fibers, rendering the entire batch structurally unsound.

Making the Right Choice for Your Project

The necessity of high vacuum is dictated by the chemical limitations of the materials involved. When working with TB8 titanium matrix composites, consider the following focus areas:

- If your primary focus is Structural Integrity: Prioritize the maintenance of vacuum levels at or better than $10^{-3}$ Pa to guarantee the elimination of brittle oxide inclusions.

- If your primary focus is Fiber Performance: Ensure the vacuum system is fully purged before heating begins to protect the SiC fiber surfaces from degradation during the temperature ramp-up.

In the fabrication of TB8 composites, high vacuum is not merely a protective measure; it is the fundamental prerequisite for atomic-level bonding.

Summary Table:

| Feature | Requirement | Impact on TB8 Composites |

|---|---|---|

| Vacuum Level | $\approx 10^{-3}$ Pa | Prevents matrix and SiC fiber oxidation |

| Surface State | Chemically Clean | Enables efficient atomic diffusion bonding |

| Oxide Inclusions | Zero Tolerance | Eliminates brittle defects for higher strength |

| Interface Quality | Metallurgical Bond | Ensures superior load transfer between matrix and fiber |

Elevate Your Material Fabrication with KINTEK

Precise control of high-vacuum environments is non-negotiable for reactive materials like TB8 titanium. KINTEK provides state-of-the-art Vacuum Hot Press and CVD systems designed to maintain rigorous $10^{-3}$ Pa levels, ensuring your composites achieve peak mechanical performance.

Backed by expert R&D and manufacturing, we offer customizable Muffle, Tube, Rotary, and Vacuum furnaces tailored to your specific lab or industrial high-temperature needs. Don't compromise on structural integrity—partner with the experts in thermal processing.

Ready to optimize your bonding process? Contact KINTEK today for a custom solution!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- How does a vacuum furnace provide precise temperature control? Achieve Unmatched Thermal Accuracy for Your Lab

- How does the annealing furnace process work? Master Material Softening and Stress Relief

- What types of heating elements are used in vacuum sintering furnaces? Choose the Right One for High-Temp Success

- What is vacuum annealing and what benefits does it provide? Achieve Superior Material Properties and Pristine Surfaces

- Why is pre-drying Rubidium Chloride raw materials essential? Ensure Safety and Purity in Vacuum Distillation

- What role do vacuum furnaces play in powder metallurgy? Achieve High-Purity, Dense Metal Parts

- Why is graphite material advantageous for vacuum furnace fixturing? Boost Efficiency and Precision

- What are the key features of vacuum performance customization? Achieve Precise Control for Your Lab Processes