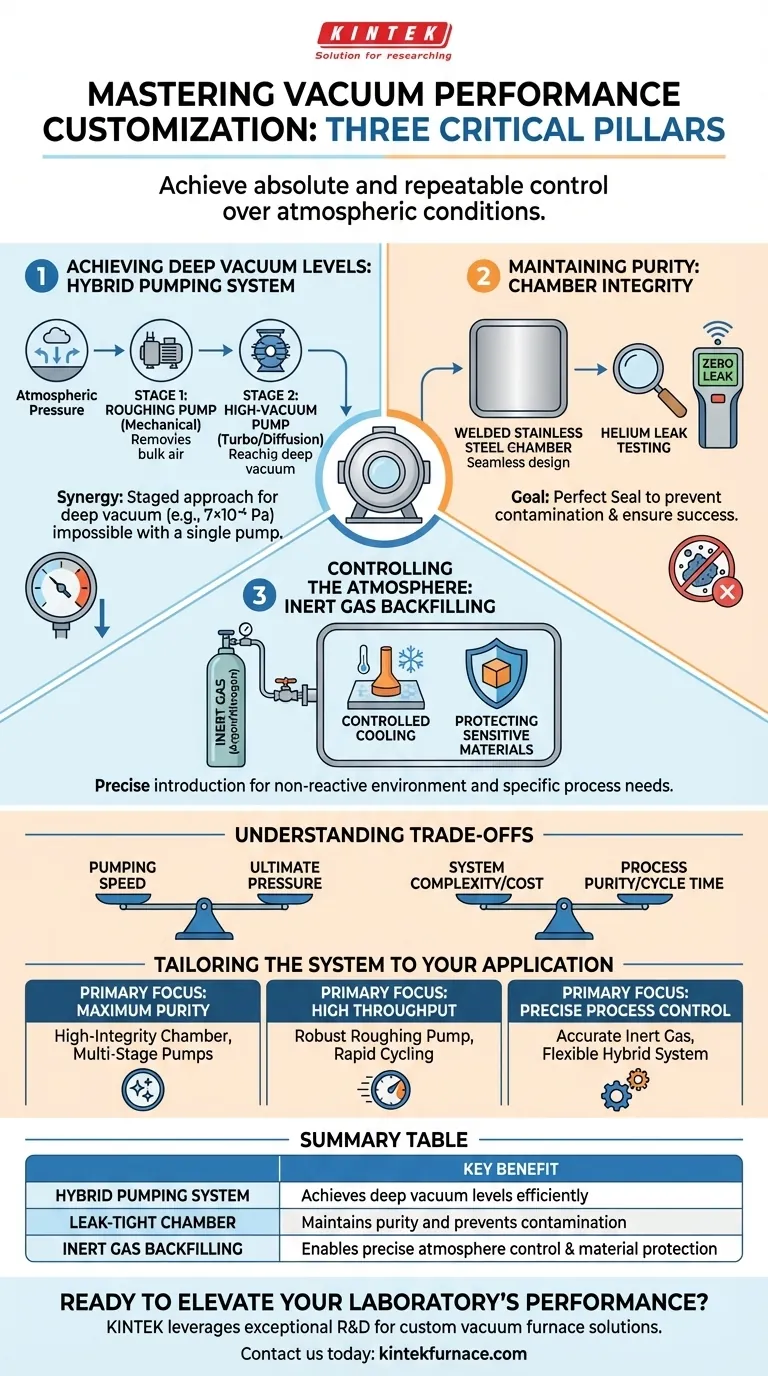

At its core, vacuum performance customization revolves around three critical pillars: creating the vacuum, maintaining its purity, and controlling the atmospheric environment. This is achieved through a combination of hybrid pumping systems to reach deep vacuum levels, leak-tight chamber construction to prevent contamination, and precise inert gas backfilling to manage the process environment.

The goal of vacuum customization is not simply to remove air. It is to achieve absolute and repeatable control over the atmospheric conditions within a chamber to guarantee the success of a specific scientific or industrial process.

The Foundation: Achieving Deep Vacuum Levels

Customizing a vacuum system begins with the ability to reach the required pressure level efficiently and reliably. This is rarely accomplished with a single pump.

The Role of a Hybrid Pumping System

No single pump is efficient across the entire pressure range from atmospheric pressure down to high vacuum. A hybrid system uses different types of pumps in stages, each optimized for a specific pressure range.

Stage 1: The Roughing Pump

The process starts with a mechanical pump, often called a "roughing pump." Its job is to do the heavy lifting, removing the vast majority of air molecules from the chamber and bringing the pressure down from atmospheric to a rough vacuum level.

Stage 2: The High-Vacuum Pump

Once the mechanical pump has done its work, a high-vacuum pump takes over. This is typically a turbomolecular or diffusion pump, which can operate effectively only at lower pressures. These pumps remove the remaining molecules to achieve deep vacuum levels, such as the 7×10⁻⁴ Pa benchmark.

The Synergy of the System

The mechanical pump continues to run, acting as a "backing pump" that vents the exhaust from the high-vacuum pump. This staged approach allows the system to reach deep vacuum levels that would be impossible for either pump to achieve on its own.

Maintaining Purity: The Importance of Chamber Integrity

Achieving a deep vacuum is pointless if unwanted air or moisture can leak back into the chamber. The integrity of the vacuum vessel is just as critical as the pumping system.

Why a Perfect Seal is Non-Negotiable

Even a microscopic leak can introduce a constant stream of gas molecules, preventing the system from reaching its target pressure or, worse, contaminating the process. This contamination can ruin sensitive materials or compromise experimental results.

Construction: Welded Stainless Steel

High-vacuum chambers are typically constructed from welded stainless steel. This material is chosen for its strength, low outgassing properties (it doesn't release trapped gases when under vacuum), and its ability to be welded into a seamless, leak-proof vessel.

Validation: Helium Leak Testing

To guarantee integrity, chambers undergo helium leak testing. Because helium atoms are incredibly small, they can penetrate leaks that other gases cannot. A detector measures for any helium escaping from a pressurized chamber, providing definitive validation of a truly leak-tight seal.

Controlling the Atmosphere: Beyond Just a Vacuum

Many advanced processes require more than just an empty space. They need the ability to precisely introduce a specific, non-reactive gas back into the chamber.

The Purpose of Inert Gas Backfilling

Inert gas backfilling is the controlled introduction of a gas like argon or nitrogen. These gases do not react with other materials, making them ideal for managing the environment without causing unwanted chemical changes like oxidation.

Use Case: Controlled Cooling

In processes like vacuum brazing or heat treating, parts must be cooled at a specific rate. Backfilling with an inert gas introduces molecules that can transfer heat away from the part, allowing for a faster and more controlled cooling cycle than would be possible in a pure vacuum.

Use Case: Protecting Sensitive Materials

When a process is complete, bringing the chamber back to atmospheric pressure with ambient air could instantly oxidize or contaminate the finished product. Backfilling with an inert gas creates a protective, non-reactive blanket around the material.

Understanding the Trade-offs

Designing a vacuum system involves balancing competing priorities. Understanding these trade-offs is key to specifying a system that meets your goals without being over-engineered.

Pumping Speed vs. Ultimate Pressure

A system designed for extremely deep vacuum levels (ultimate pressure) may have a slower overall pumping speed. Conversely, a system optimized for high throughput may sacrifice some of its ultimate vacuum capability for the ability to cycle chambers more quickly.

System Complexity vs. Cost and Maintenance

A sophisticated hybrid pump system with multiple stages and controls offers superior performance and flexibility. However, it comes with a higher initial cost and more complex maintenance requirements compared to a simpler, single-pump setup for less demanding applications.

Process Purity vs. Cycle Time

Utilizing high-purity inert gas and performing multiple purge cycles ensures the cleanest possible environment. This dedication to purity, however, adds time to each process cycle, which may be a critical factor in a high-volume production setting.

Tailoring the System to Your Application

The optimal vacuum system configuration depends entirely on your primary objective.

- If your primary focus is maximum purity for sensitive processes: Prioritize a high-integrity, welded stainless steel chamber validated with helium leak testing and a multi-stage, high-vacuum pumping system.

- If your primary focus is high throughput for industrial production: Emphasize a robust mechanical roughing pump with high pumping speed and a system designed for rapid cycling.

- If your primary focus is precise process control for research or heat treating: Invest in a system with accurate inert gas backfilling capabilities and a flexible hybrid pump system to manage specific process steps.

Ultimately, a customized vacuum system empowers you to master the environment your process demands.

Summary Table:

| Feature | Description | Key Benefit |

|---|---|---|

| Hybrid Pumping System | Uses mechanical and high-vacuum pumps in stages | Achieves deep vacuum levels efficiently |

| Leak-Tight Chamber | Welded stainless steel construction with helium leak testing | Maintains purity and prevents contamination |

| Inert Gas Backfilling | Controlled introduction of gases like argon or nitrogen | Enables precise atmosphere control and material protection |

Ready to elevate your laboratory's performance with a custom vacuum solution? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for purity, throughput, and control. Contact us today to discuss how we can optimize your processes and deliver reliable results!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- Why are vacuum furnaces considered important in various industries? Unlock Superior Material Performance

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- Why are some vacuum furnaces backfilled with a partial pressure gas? Prevent Alloy Depletion in High-Temp Processes

- What is the role of the temperature control system in a vacuum furnace? Achieve Precise Material Transformations

- How does vacuum heat treatment reduce workpiece deformation? Achieve Superior Dimensional Stability