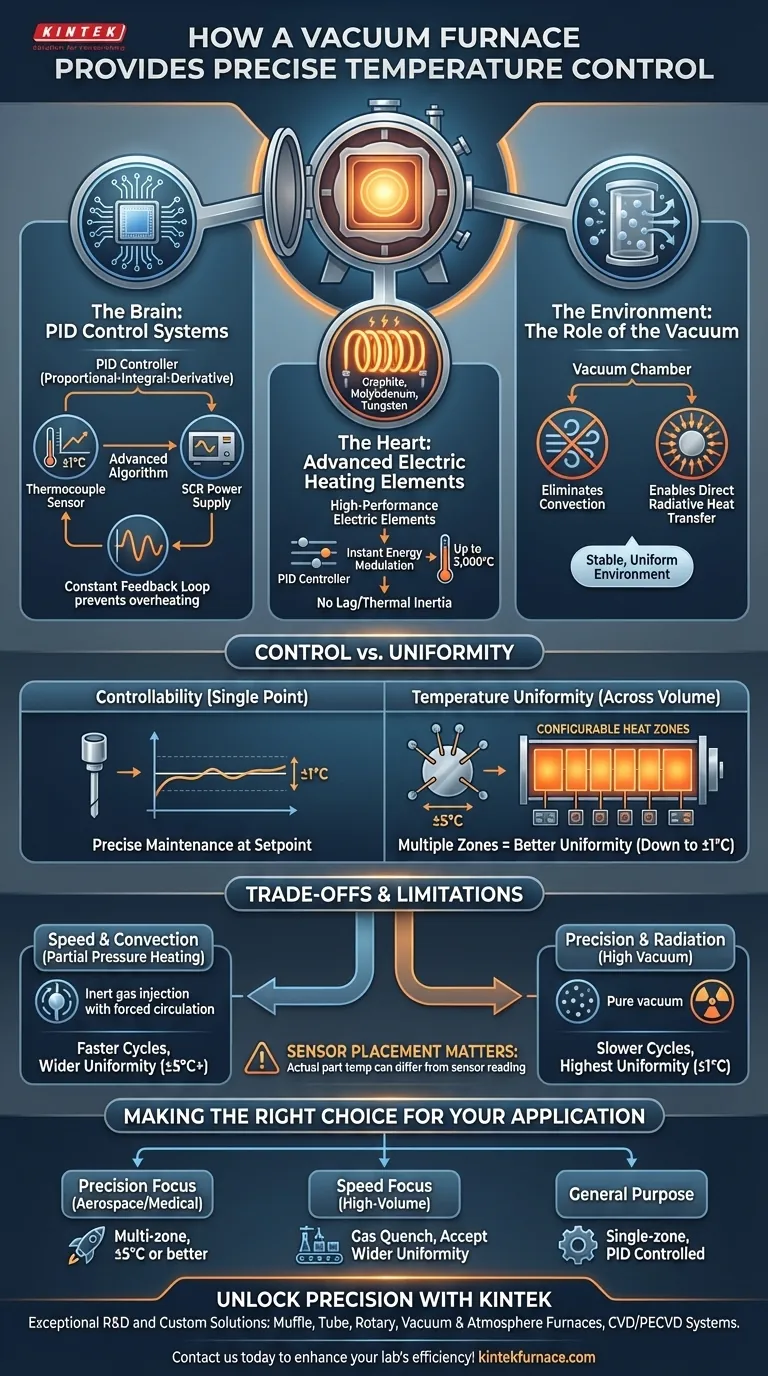

At its core, a vacuum furnace achieves precise temperature control through a sophisticated interplay of three key elements. An advanced digital controller acts as the brain, a highly responsive electric heating system serves as the heart, and the vacuum itself creates a uniquely stable environment by eliminating the unpredictable variables of air. This combination allows for extremely accurate energy input and uniform heat distribution, leading to repeatable results with tolerances as tight as ±1°C.

Achieving precise temperature in a vacuum furnace is not the result of a single component, but rather an engineered system. An advanced PID controller, specialized electric heating elements, and the physics of the vacuum environment work in concert to eliminate thermal variables and deliver unparalleled control over the heat treatment process.

The Core Components of Precision Control

To understand how this precision is possible, it's essential to break down the system into its fundamental components. Each part plays a distinct and critical role in achieving and maintaining the target temperature.

The Brain: PID Control Systems

The central nervous system of the furnace is its PID (Proportional-Integral-Derivative) controller. Think of this as an advanced cruise control system for temperature.

The controller continuously measures the temperature via thermocouples and compares it to the desired setpoint. It then uses a sophisticated algorithm to precisely adjust the power sent to the heating elements via a Silicon Controlled Rectifier (SCR) power supply. This constant feedback loop prevents overheating or undercooling, ensuring the temperature remains exceptionally stable.

The Heart: Advanced Electric Heating Elements

Unlike combustion-based systems, vacuum furnaces use high-performance electric heating elements. These are typically made from materials like graphite, molybdenum, or tungsten, chosen for their ability to handle extreme temperatures up to 3,000°C.

Because they are electric, the energy delivered can be modulated instantly and cleanly by the PID controller. There is no lag or thermal inertia associated with burning fuel, allowing for a level of responsiveness that is critical for tight temperature control.

The Environment: The Role of the Vacuum

The vacuum itself is a crucial element of control. By removing air molecules from the chamber, the furnace virtually eliminates heat transfer through convection.

In a standard atmosphere, convection creates unpredictable air currents and hot spots. In a vacuum, heat is transferred primarily through radiation, which is a much more direct and uniform method. This ensures that all surfaces of the part are heated evenly without interference from turbulent air.

From Control to Uniformity: How Precision is Measured

The terms "control" and "uniformity" are often used together, but they describe different aspects of furnace performance. Understanding the distinction is key to evaluating a system's capabilities for a specific application.

Understanding Controllability vs. Uniformity

Controllability refers to how closely the furnace can maintain the temperature at a single sensor point relative to the setpoint. Modern systems often achieve a controllability of ±1°C.

Temperature uniformity, however, refers to the maximum temperature variation across the entire working volume or the part itself. Because of natural hot and cold spots, uniformity is typically a wider range, often specified as ±5°C. Achieving better uniformity requires additional engineering.

The Impact of Configurable Heat Zones

To improve uniformity, high-performance furnaces use multiple, configurable heating zones. Instead of one large heating element, the furnace is divided into several smaller zones, each with its own power control and often its own thermocouple.

This allows the PID controller to intelligently send more power to cooler areas and less power to hotter areas, actively counteracting thermal gradients. This is how furnaces achieve the exceptional uniformity (down to ±1°C) required for sensitive processes like brazing aerospace components or sintering medical implants.

Understanding the Trade-offs and Limitations

While a vacuum furnace offers superior control, its performance is subject to the laws of physics and specific operational choices. Understanding these trade-offs is crucial for process optimization.

The Challenge of Convective Heating

For faster heating or cooling cycles, a small amount of inert gas (like argon or nitrogen) can be introduced into the chamber, a process known as partial pressure heating or gas quenching. This re-introduces a convective heat transfer element.

While this speeds up the process significantly, it comes at the cost of temperature uniformity. The forced circulation can create temperature differences, widening the uniformity to a range of ±5°C or more. This is a deliberate trade-off between cycle time and absolute precision.

Sensor Placement and Accuracy

The entire control system relies on the data from its thermocouples. The furnace's indicated temperature value can be highly accurate—often within ±1.5°C of the actual thermocouple reading.

However, if the thermocouple is not placed correctly relative to the workload, the part's actual temperature may differ from what the controller is reading. Proper setup and, in some cases, using multiple thermocouples attached directly to the part are essential for guaranteeing that the part itself reaches the desired temperature.

Making the Right Choice for Your Application

The ideal level of temperature control depends entirely on your material, your process, and your production goals.

- If your primary focus is maximum precision and repeatability (e.g., aerospace, medical): Prioritize furnaces with multiple, independently controlled heat zones and specifications for uniformity of ±5°C or better.

- If your primary focus is faster cycle times for high-volume production: Consider a furnace with robust partial pressure and gas quenching capabilities, but be prepared to accept a wider temperature uniformity during those phases.

- If your primary focus is general-purpose heat treating: A well-built single-zone furnace with a modern PID controller and good insulation often provides a sufficient and cost-effective balance of performance.

By understanding these interconnected systems, you can confidently select and operate a furnace that meets the precise demands of your process.

Summary Table:

| Component | Role in Precision Control | Key Features |

|---|---|---|

| PID Controller | Brain of the system, adjusts power via feedback loop | Achieves ±1°C controllability, uses SCR power supply |

| Electric Heating Elements | Heart, provides instant energy modulation | Made from graphite, molybdenum, or tungsten; handles up to 3,000°C |

| Vacuum Environment | Eliminates convection for uniform heating | Transfers heat via radiation, ensures stable conditions |

| Multiple Heat Zones | Enhances temperature uniformity | Configurable zones improve uniformity to ±1°C in sensitive processes |

Unlock Precision in Your Heat Treatment Processes with KINTEK

Are you striving for exact temperature control in your aerospace, medical, or research applications? KINTEK leverages exceptional R&D and in-house manufacturing to deliver advanced high-temperature furnace solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements.

Contact us today to discuss how our furnaces can enhance your lab's efficiency and accuracy!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why is a vacuum environment essential for sintering Titanium? Ensure High Purity and Eliminate Brittleness

- What are the advantages of a vacuum hot pressing sintering furnace for rare earth copper composites? Density & Purity

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- How does pressure application in a vacuum hot press furnace facilitate sintering of copper composites? Optimize Density