At their core, heat treatment and vacuum furnaces are innovation engines because they give industries the power to fundamentally change and improve the physical properties of materials. By creating a precisely controlled, ultra-clean environment free from atmospheric contamination, these furnaces enable the creation of components with superior strength, purity, and durability that would be impossible to achieve with conventional heating methods.

The true contribution of vacuum furnace technology is not just heating materials, but providing a pristine, controlled environment. This allows for the deliberate enhancement of material properties, turning standard metals and alloys into high-performance components that define modern aerospace, automotive, and semiconductor applications.

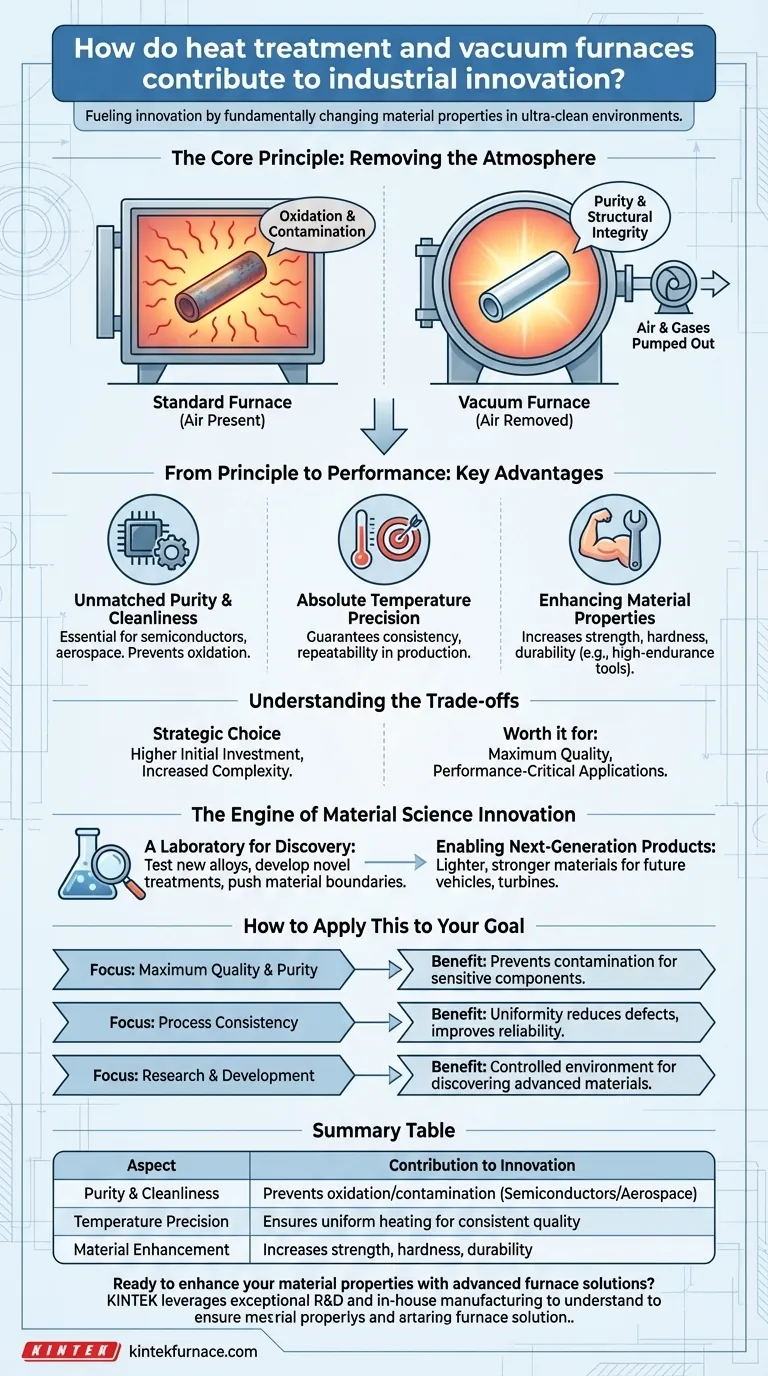

The Core Principle: Removing the Atmosphere

The innovation behind vacuum furnaces begins with a simple but powerful concept: removing the air before applying heat. This fundamentally changes the outcome of the heat treatment process.

What is a Vacuum Furnace?

A vacuum furnace is a specialized chamber that heats materials to very high temperatures only after the air and other gases inside have been pumped out, creating a condition below atmospheric pressure.

This process prevents the hot material from reacting with oxygen, nitrogen, and water vapor, which are always present in a standard furnace.

Why the Vacuum is Critical

Heating metals in the presence of air causes oxidation (rusting) and other unwanted chemical reactions that can compromise the material's surface and structural integrity.

A vacuum environment eliminates these reactions. This ensures the material remains chemically pure, free from surface contamination, and structurally sound, which is critical for high-performance applications.

From Principle to Performance: Key Advantages

The controlled environment of a vacuum furnace translates directly into measurable improvements in product quality and manufacturing efficiency.

Unmatched Purity and Cleanliness

By preventing oxidation, the furnace delivers an exceptionally clean product. This is non-negotiable in industries like semiconductors, where microscopic contaminants can ruin a microchip, or aerospace, where surface integrity is vital for safety.

Absolute Temperature Precision

Vacuum furnaces offer incredibly precise and uniform temperature control. This guarantees that every part of the component, and every component in a batch, receives the exact same thermal processing.

This consistency and repeatability are essential for meeting the stringent quality standards of modern manufacturing and optimizing production lines.

Enhancing Intrinsic Material Properties

The primary goal of heat treatment is to improve a material. Vacuum processing excels at this, enabling processes that increase strength, hardness, and durability.

This is how standard steel is turned into a high-endurance cutting tool, or how an aluminum alloy is strengthened for use in a critical aircraft structure.

Understanding the Trade-offs

While powerful, vacuum furnace technology is a strategic choice that comes with specific considerations. It is not the universal solution for all heating applications.

Higher Initial Investment

Vacuum furnaces are complex systems that represent a significant capital investment compared to traditional atmospheric furnaces. The pumps, chambers, and control systems are highly specialized.

Increased Process Complexity

Operating and maintaining a vacuum system requires specialized knowledge. Process cycles can also be longer due to the time needed to pump down the chamber to the required vacuum level.

Suitability for the Application

For simple heating tasks where surface oxidation is not a concern, a conventional furnace may be more cost-effective. A vacuum furnace is an investment in quality and performance where those attributes are paramount.

The Engine of Material Science Innovation

Beyond production, vacuum furnaces are indispensable tools for research and development, directly fueling the discovery of next-generation materials.

A Laboratory for Discovery

These furnaces provide scientists and engineers with a perfect, repeatable environment to study material behavior under controlled thermal conditions.

This allows them to test new alloys, develop novel heat treatment cycles, and push the boundaries of what materials can do, advancing the entire field of material science.

Enabling Next-Generation Products

The discoveries made in a lab furnace directly lead to commercial innovation. A stronger, lighter alloy tested in a vacuum furnace today might become the frame of a more fuel-efficient car or a more durable jet engine turbine blade tomorrow.

How to Apply This to Your Goal

Your reason for considering vacuum heat treatment will determine what aspect of the technology is most critical.

- If your primary focus is maximum product quality and purity: The furnace's ability to prevent oxidation and contamination is its most valuable feature, ensuring superior material properties for sensitive aerospace, medical, or electronic components.

- If your primary focus is process consistency for high-volume manufacturing: The precise temperature control and uniformity guarantee that every single part meets exact specifications, reducing defects and improving reliability.

- If your primary focus is research and development: The controlled, repeatable environment makes the vacuum furnace an essential tool for discovering and qualifying the advanced materials that will drive future innovation.

Mastering the properties of materials is the foundation of industrial leadership, and vacuum heat treatment is a key technology for achieving that mastery.

Summary Table:

| Aspect | Contribution to Innovation |

|---|---|

| Purity & Cleanliness | Prevents oxidation and contamination, essential for semiconductors and aerospace components. |

| Temperature Precision | Ensures uniform heating for consistent quality in high-volume manufacturing. |

| Material Enhancement | Increases strength, hardness, and durability for high-performance applications. |

| R&D Enablement | Provides controlled environments for developing next-generation materials and alloys. |

Ready to enhance your material properties with advanced furnace solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with high-temperature furnace solutions, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements. Contact us today to discuss how our tailored solutions can drive your industrial innovation forward!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

People Also Ask

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity