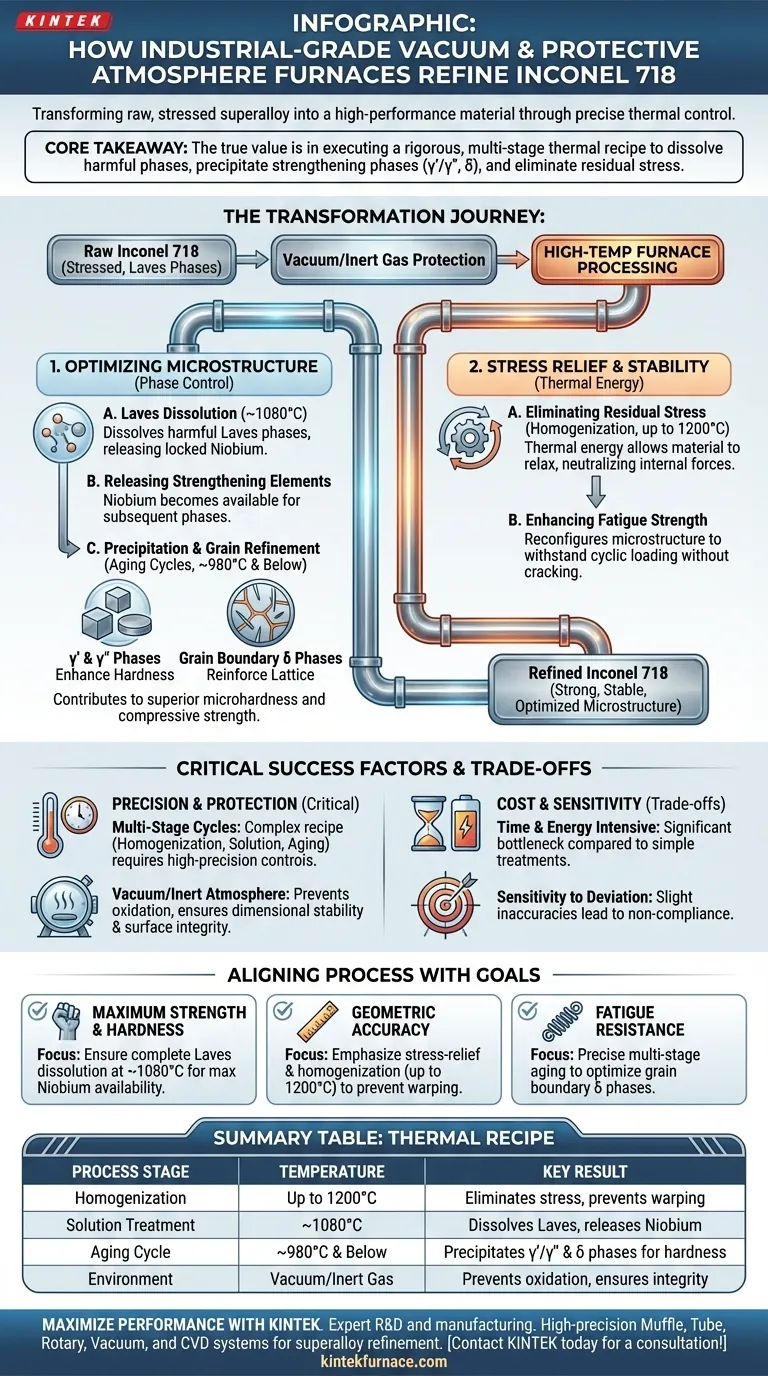

Industrial-grade vacuum and protective atmosphere furnaces are critical for transforming Inconel 718 from a raw, stressed state into a high-performance superalloy. By maintaining precise thermal windows and controlled environments, these furnaces dissolve harmful Laves phases, induce the precipitation of strengthening phases, and eliminate residual stresses accumulated during fabrication.

Core Takeaway The true value of these furnaces lies in their ability to execute a rigorous, multi-stage thermal recipe. They facilitate the dissolution of segregation-prone elements and drive the precipitation of $\gamma'/\gamma''$ and $\delta$ phases, which are fundamental to achieving Inconel 718’s required microhardness, compressive strength, and dimensional stability.

Optimizing Microstructure Through Phase Control

Dissolving Harmful Byproducts

During the initial fabrication or printing of Inconel 718, harmful Laves phases often form within the material.

These phases sequester valuable alloying elements and weaken the structure. Industrial furnaces utilize precise solution treatments, such as holding the material at approximately 1080 °C, to effectively dissolve these Laves phases back into the matrix.

Releasing Strengthening Elements

Once the Laves phases are dissolved, the niobium locked within them is released.

This niobium is the key ingredient required for the subsequent precipitation of strengthening phases. Without this controlled dissolution, the material cannot reach its potential hardness.

Inducing Grain Refinement

The controlled cooling and aging cycles promote the formation of $\gamma'$ (gamma prime) and $\gamma''$ (gamma double prime) phases.

Simultaneously, the process precipitates grain boundary $\delta$ (delta) phases. Together, these phases reinforce the lattice structure, significantly enhancing microhardness and compressive strength.

Stress Relief and Material Stability

Eliminating Residual Stress

Fabrication processes, particularly 3D printing, introduce significant residual stress into Inconel components.

High-temperature furnaces address this through homogenization cycles, sometimes reaching up to 1200°C. This thermal energy allows the material to relax, effectively neutralizing internal forces that could cause warping or failure.

Enhancing Fatigue Strength

By reconfiguring the microstructure and removing stress, the furnace treatment directly improves fatigue strength.

This ensures that components can withstand cyclic loading over time without developing cracks, a critical requirement for aerospace and industrial applications.

The Necessity of Precision Control

Managing Multi-Stage Cycles

Inconel 718 requires a complex thermal recipe, including homogenization, solution treatment (e.g., 980°C), and multi-stage aging.

Industrial furnaces provide the high-precision heating and cooling controls necessary to transition between these stages without overshooting target temperatures.

Protecting the Surface

The use of a vacuum or protective atmosphere is not merely a feature; it is a requirement.

These environments prevent oxidation and surface contamination at high temperatures, ensuring the dimensional stability and surface integrity of the final part remain uncompromised.

Understanding the Trade-offs

The Cost of Precision

Achieving this level of microstructural refinement is time-intensive and energy-demanding.

The multi-stage process—homogenization, solution treating, and aging—can take significant time to complete, representing a major bottleneck in production throughput compared to simpler heat treatments.

Sensitivity to Deviation

Inconel 718 is unforgiving of thermal inaccuracy.

Even slight deviations from the specific temperature windows (e.g., missing the 1080°C target for Laves dissolution) can result in incomplete phase transformation or excessive grain growth, rendering the part non-compliant.

Making the Right Choice for Your Goal

To maximize the utility of your heat treatment process, align your furnace parameters with your specific engineering requirements:

- If your primary focus is maximum strength and hardness: Prioritize cycles that ensure complete dissolution of Laves phases at 1080°C to maximize Niobium availability for $\gamma'/\gamma''$ precipitation.

- If your primary focus is geometric accuracy: Emphasize the stress-relief and homogenization stages (up to 1200°C) to eliminate residual stresses that cause warping.

- If your primary focus is fatigue resistance: Ensure your recipe includes a precise multi-stage aging process to optimize the grain boundary $\delta$ phases.

The furnace is not just a heater; it is the precision tool that dictates the final mechanical identity of your Inconel 718 components.

Summary Table:

| Process Stage | Temperature Range | Key Result for Inconel 718 |

|---|---|---|

| Homogenization | Up to 1200°C | Eliminates residual stress and prevents warping |

| Solution Treatment | ~1080°C | Dissolves Laves phases and releases Niobium |

| Aging Cycle | ~980°C & Below | Precipitates γ'/γ'' and δ phases for hardness |

| Environment | Vacuum/Inert Gas | Prevents oxidation and ensures surface integrity |

Maximize the Performance of Your Inconel 718 Components

Don't let thermal inaccuracy compromise your material's integrity. Backed by expert R&D and manufacturing, KINTEK offers high-precision Muffle, Tube, Rotary, Vacuum, and CVD systems designed to handle the rigorous multi-stage cycles required for superalloy refinement. Whether you need to dissolve Laves phases or ensure absolute dimensional stability, our customizable high-temp furnaces provide the atmosphere control and temperature uniformity your lab demands.

Ready to optimize your heat treatment process? Contact KINTEK today for a consultation!

Visual Guide

References

- Sebastian Marian Zaharia, Mihai Alin Pop. Mechanical Properties and Microstructure of Inconel 718 Lattice Structures Produced by Selective Laser Melting Process. DOI: 10.3390/ma17030622

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What types of pumps are used for vacuum brazing? Master the Staged System for High-Purity Brazing

- What is the working principle of a vacuum furnace? Achieve High-Purity Heat Treatment for Sensitive Materials

- What technical requirements must a furnace meet for Inconel 718 hardening? Master Precision Aging & Cooling

- How do multi-chamber designs improve energy efficiency? Cut Costs with Continuous Thermal Processing

- What factors influence the price of vacuum furnaces? Key Drivers from Size to Automation

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- How are vacuum brazing challenges overcome in furnace design? Master Precision and Purity for Strong Joints

- What temperature capabilities does the vacuum furnace system offer? Discover Precision Heating for Demanding Applications