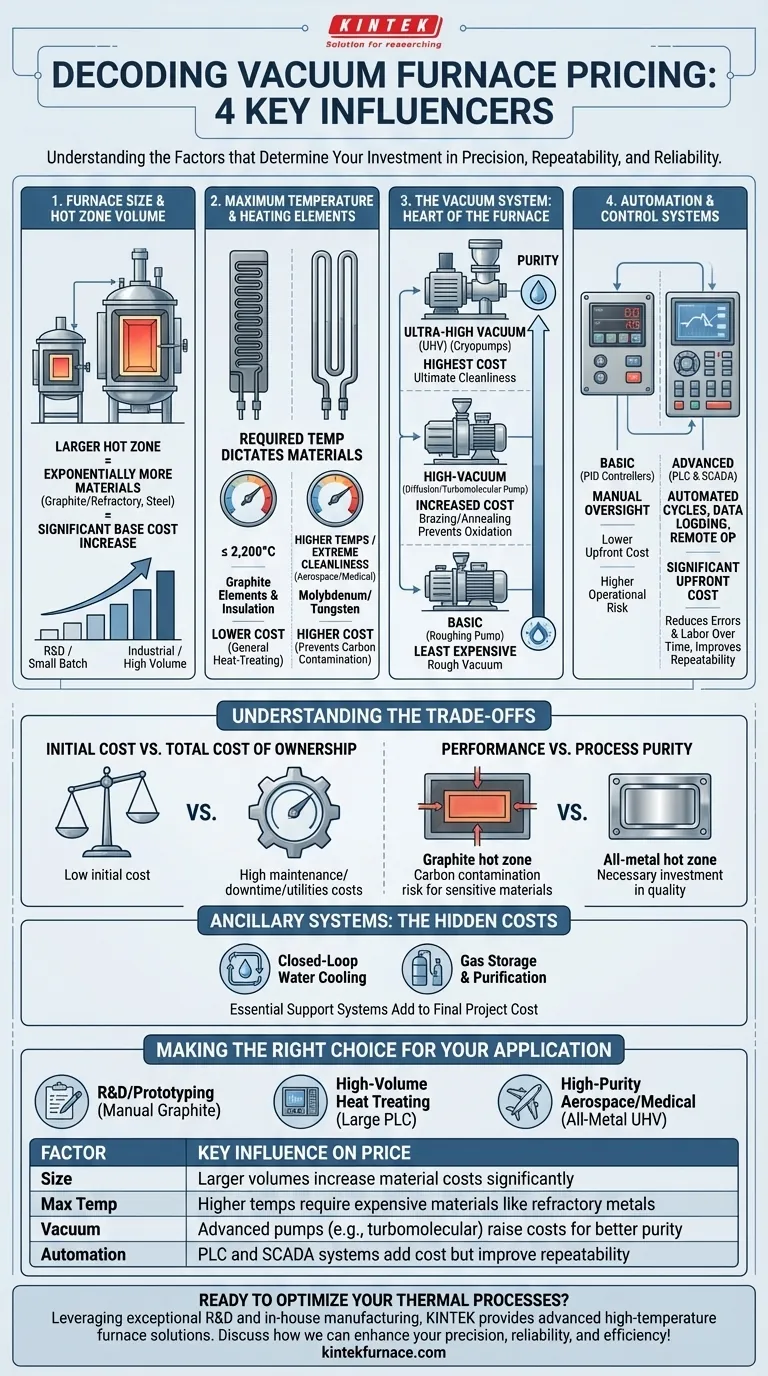

At its core, the price of a vacuum furnace is determined by four primary factors: its size, its maximum operating temperature, the quality of its vacuum system, and its level of automation. These elements dictate the furnace's capabilities and, consequently, its cost, which can range from tens of thousands of dollars for a small laboratory unit to well over a million for a large, highly specialized industrial system.

The final price of a vacuum furnace is not just a reflection of its physical components. It is a direct investment in process precision, repeatability, and long-term operational reliability for critical thermal applications like brazing, annealing, and sintering.

The Core Components Driving Cost

Understanding the price of a vacuum furnace requires looking at its key subsystems. Each component adds capability, but also complexity and cost.

Furnace Size and Hot Zone Volume

The hot zone is the usable internal volume of the furnace where the workload is heated. A larger hot zone requires exponentially more raw materials—graphite or refractory metals for insulation and elements, and steel for the chamber—driving up the base cost significantly.

Industrial-scale furnaces designed for large parts or high-volume batches are inherently more expensive than smaller furnaces used for research and development.

Maximum Temperature and Heating Elements

The required operating temperature directly influences the materials used for the heating elements and insulation, creating a major cost inflection point.

Furnaces using graphite elements and insulation are generally less expensive and suitable for many common heat-treating applications up to around 2,200°C.

For higher temperatures or processes requiring extreme cleanliness (like medical or aerospace), furnaces with refractory metal hot zones (using molybdenum or tungsten) are necessary. These materials are far more expensive than graphite but prevent carbon contamination and offer superior performance.

The Vacuum System: The Heart of the Furnace

The quality of the vacuum system dictates the purity of the operating environment. A system is specified by its ultimate vacuum level and its pump-down speed.

A basic system for rough vacuum might only use a single mechanical "roughing" pump. This is the least expensive option.

High-vacuum systems, required for brazing and annealing, add a diffusion pump or turbomolecular pump in series with the roughing pump. This significantly increases cost but is essential for achieving the low pressures needed to prevent oxidation.

Ultra-high vacuum (UHV) systems may add cryopumps for the highest level of cleanliness, representing the most expensive tier of vacuum performance.

Automation and Control Systems

The level of automation determines the furnace's ease of use, process repeatability, and labor requirements.

Basic furnaces use simple PID controllers that require manual oversight. More advanced systems use Programmable Logic Controllers (PLCs) and SCADA software, which automate entire heating and cooling cycles, log all process data for certification, and allow for remote operation. This advanced control adds significant upfront cost but reduces operational errors and labor over time.

Understanding the Trade-offs

Choosing a furnace is not about finding the cheapest option; it's about balancing cost against technical requirements and long-term value.

Initial Cost vs. Total Cost of Ownership

A furnace with a lower initial price may use lower-quality components, such as less-durable vacuum pumps or seals. This can lead to higher maintenance costs, more frequent downtime, and greater consumption of utilities like water and power, increasing the total cost of ownership.

Performance vs. Process Purity

A graphite hot zone is a cost-effective choice for general-purpose heat treating of tool steels. However, using it for processing oxygen-sensitive materials like titanium could lead to carbon contamination and part failure. In this case, the higher initial cost of an all-metal hot zone is a necessary investment in quality.

Ancillary Systems: The Hidden Costs

The furnace chamber itself is only part of the total investment. You must also account for essential support systems.

A closed-loop water cooling system is a significant expense but conserves water and protects the furnace from contaminants found in city or well water. Likewise, systems for storing and purifying process gases like Argon or Nitrogen for backfilling and quenching add to the final project cost.

Making the Right Choice for Your Application

Selecting the right furnace requires a clear understanding of your primary goal.

- If your primary focus is R&D or small-batch prototyping: A smaller, manually operated furnace with a graphite hot zone offers the most cost-effective flexibility.

- If your primary focus is high-volume industrial heat treating: Investing in a larger furnace with robust PLC automation will deliver the lowest cost-per-part through high throughput and process repeatability.

- If your primary focus is high-purity brazing for aerospace or medical: Prioritize a furnace with an all-metal hot zone and a high-performance, oil-free turbomolecular or cryopump vacuum system.

By understanding these core drivers, you can specify a furnace that meets not just your budget, but your precise technical and operational goals.

Summary Table:

| Factor | Key Influence on Price |

|---|---|

| Size and Hot Zone Volume | Larger volumes increase material costs significantly |

| Maximum Temperature | Higher temps require expensive materials like refractory metals |

| Vacuum System Quality | Advanced pumps (e.g., turbomolecular) raise costs for better purity |

| Automation Level | PLC and SCADA systems add cost but improve repeatability |

Ready to optimize your thermal processes with a tailored vacuum furnace? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to discuss how we can enhance your precision, reliability, and efficiency!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity

- What is the role of a vacuum furnace in the solid-phase synthesis of TiC/Cu? Master High-Purity Material Engineering

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance