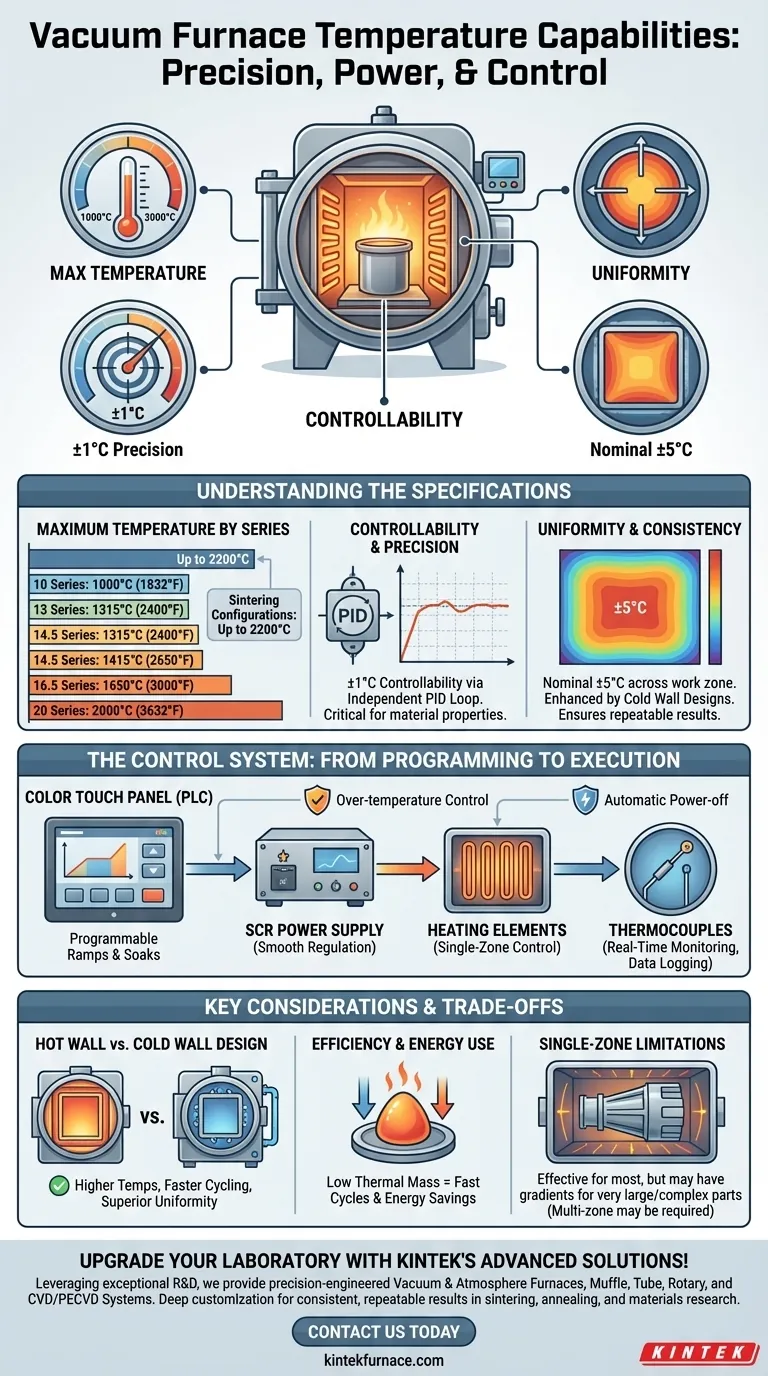

At its core, the vacuum furnace system provides a wide spectrum of temperature capabilities, with specific models reaching maximum temperatures ranging from 1000°C (1832°F) to over 2000°C (3632°F). Beyond maximum heat, the system is engineered for exceptional precision, offering temperature controllability of ±1°C and uniformity rated at a nominal ±5°C.

The true capability of a furnace is not defined by its maximum temperature alone, but by its ability to precisely control and uniformly maintain that temperature. This system combines high heat with advanced process control to ensure consistent, repeatable results for demanding material applications.

Understanding the Temperature Specifications

To evaluate if this furnace meets your needs, you must look at three key metrics: maximum temperature, controllability, and uniformity. Each plays a distinct role in the success of your thermal process.

Maximum Temperature by Series

The system is offered in different series, each with a specific thermal ceiling. This allows you to select a model tailored to your process requirements without over-investing in unnecessary capacity.

- 10 Series: 1000°C (1832°F)

- 13 Series: 1315°C (2400°F)

- 14.5 Series: 1415°C (2650°F)

- 16.5 Series: 1650°C (3000°F)

- 20 Series: 2000°C (3632°F)

Some vacuum sintering furnace configurations can achieve even higher temperatures, reaching up to 2200°C.

Controllability: The Power of Precision

The system offers ±1°C controllability. This specification refers to the furnace's ability to achieve and hold a specific temperature setpoint as measured by the control thermocouple.

This level of precision is critical for processes where slight temperature deviations can dramatically alter material properties. It is managed by an independent PID loop control, which constantly adjusts power to maintain the target temperature.

Uniformity: Ensuring Consistent Results

Temperature uniformity is rated at a nominal ±5°C. This means that at a given setpoint, the temperature will not vary by more than 5°C across the entire usable work zone.

Excellent uniformity is vital for ensuring that a large component or a batch of smaller parts receives the exact same thermal treatment, preventing inconsistencies and ensuring predictable outcomes. This is often enhanced by cold wall furnace designs, which promote faster and more even heating.

The Control System: From Programming to Execution

High-performance temperature hardware is only effective when paired with a sophisticated control system. This furnace uses an integrated PLC-based system to translate your process requirements into reliable, automated furnace operations.

Programmable Ramps and Soaks

The system features a color touch panel with a PLC that allows you to program complex thermal cycles. You can define specific heating rates (ramps) and hold times at target temperatures (soaks).

This is essential for metallurgical processes like annealing, tempering, and sintering, which depend on a precise, time-dependent thermal profile.

Real-Time Monitoring and Safety

The system uses thermocouples to provide real-time temperature measurement. All process data, including temperature and vacuum levels, can be logged for quality assurance and process validation.

Safety is managed through features like over-temperature control, which protects the furnace and workload, and an automatic power-off function when the furnace door is opened.

Power Regulation and Heat Control

Heating is managed by an SCR Power Supply, which provides smooth and precise regulation of power to the heating elements.

The standard configuration uses single-zone heat control, where the entire heating chamber is managed as one unit. This is effective for a wide range of applications and contributes to the system's operational simplicity and reliability.

Understanding the Trade-offs

No system is perfect for every scenario. Understanding the inherent design choices and their implications is key to making an informed decision.

Hot Wall vs. Cold Wall Design

The references note that cold wall furnaces offer higher operating temperatures, faster cycling, and superior temperature uniformity compared to older hot wall designs. While the system benefits from this modern approach, it's important to confirm the design of the specific model you are considering.

Efficiency and Energy Use

The furnace is designed with a low thermal mass (small heat storage), which allows for fast temperature rise and fall times. This not only speeds up your process cycles but also provides significant energy savings compared to traditional heavy refractory furnaces.

The Limitation of Single-Zone Control

While single-zone heat control is reliable and sufficient for most workloads, it can be a limitation for very large or geometrically complex parts. In such cases, temperature gradients can sometimes form across the part, potentially falling outside the nominal ±5°C uniformity specification. For these niche applications, a multi-zone furnace might be required.

Making the Right Choice for Your Application

Your ideal furnace configuration depends entirely on your specific process goals.

- If your primary focus is high-temperature sintering or materials research: Prioritize the 20 series or other high-temperature models (up to 2200°C) and confirm the ±5°C uniformity meets your material's sensitivity.

- If your primary focus is standard heat treating (annealing, tempering): The 10, 13, or 14.5 series will likely provide sufficient temperature with the necessary process control for excellent, repeatable results.

- If your primary focus is process validation and quality control: Leverage the system's data logging, PLC programmability, and tight ±1°C controllability to ensure every cycle is executed and documented perfectly.

By matching the system's specific capabilities to your application's demands, you can ensure you are selecting the right tool for the job.

Summary Table:

| Specification | Details |

|---|---|

| Maximum Temperature Range | 1000°C to 2200°C (1832°F to 3992°F) |

| Temperature Controllability | ±1°C |

| Temperature Uniformity | ±5°C |

| Key Series | 10 Series (1000°C), 13 Series (1315°C), 14.5 Series (1415°C), 16.5 Series (1650°C), 20 Series (2000°C) |

| Control Features | PLC-based, programmable ramps and soaks, real-time monitoring, SCR power supply |

Upgrade your laboratory with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with precision-engineered products like Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, delivering consistent, repeatable results for applications such as sintering, annealing, and materials research. Contact us today to discuss how our tailored furnace systems can enhance your thermal processing efficiency and reliability!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?

- What are the advantages of a vacuum hot pressing sintering furnace for rare earth copper composites? Density & Purity

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure

- Why must sintering equipment maintain a high vacuum for high-entropy carbides? Ensure Phase Purity and Peak Density