For advanced ceramics, the manufacturing environment is everything. A vacuum furnace is essential for their production because it provides a high-temperature, low-pressure environment free from atmospheric contamination. This controlled setting is critical for processes like sintering, enabling the creation of exceptionally dense, high-purity ceramic materials with the superior mechanical and thermal properties required for extreme applications.

The fundamental contribution of a vacuum furnace is not just heating, but purification and densification. By removing the reactive atmosphere that would compromise the material at extreme temperatures, it allows for the creation of ceramics with near-perfect microstructures and superior performance.

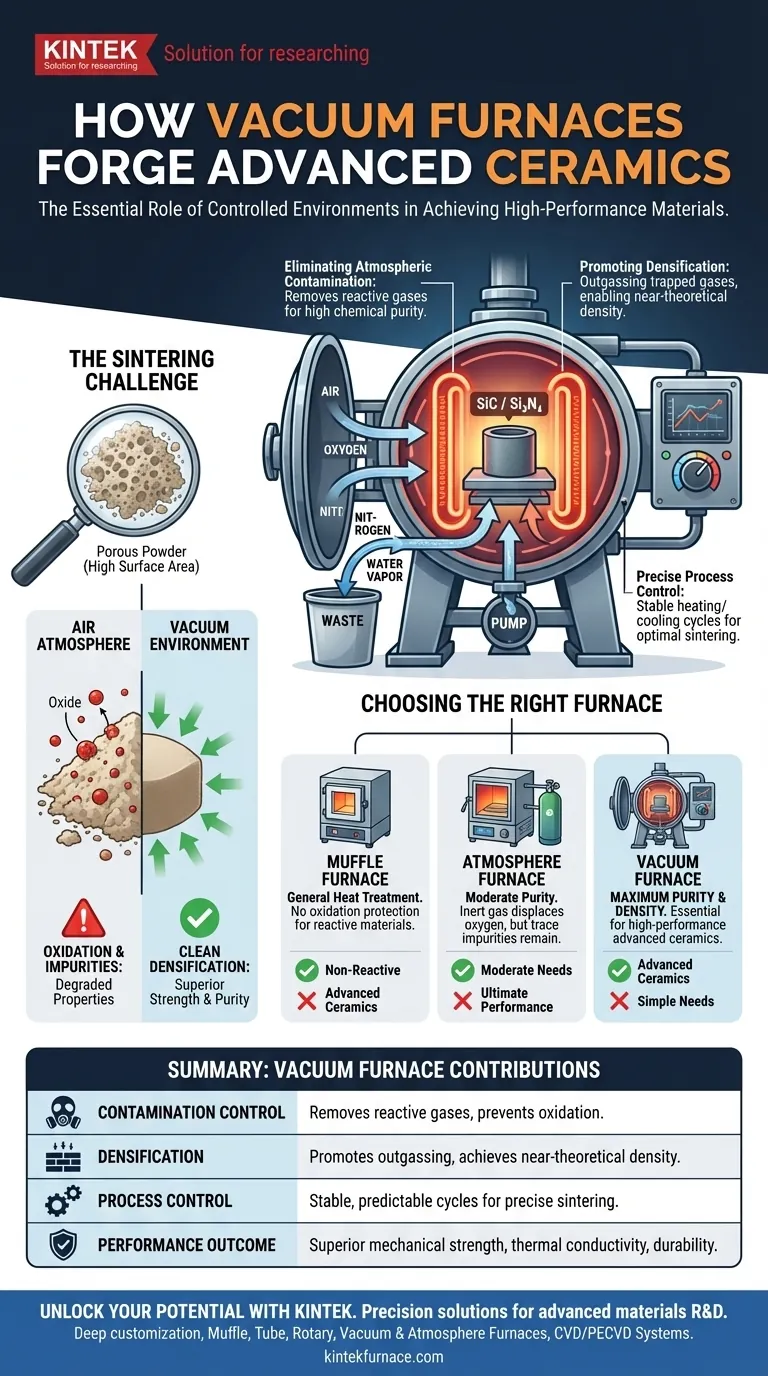

The Challenge of Sintering Advanced Ceramics

To understand the role of a vacuum furnace, we must first understand the primary challenge in creating materials like Silicon Nitride (Si₃N₄) or Silicon Carbide (SiC). The goal is to transform a powder into a solid, monolithic part.

Why High Temperatures Create Problems

The process of consolidating ceramic powders into a dense solid is called sintering. This requires extremely high temperatures, often exceeding 1,400°C (2,552°F).

At these temperatures, the material is highly reactive. If exposed to a normal atmosphere, the ceramic would readily react with oxygen and other gases, forming oxides and other impurities that degrade its final properties.

The Goal: Near-Theoretical Density

The ultimate objective of sintering is to achieve a density as close to the material's theoretical maximum as possible. This involves eliminating the microscopic voids, or porosity, between the initial powder particles.

Low porosity is directly linked to high mechanical strength, thermal conductivity, and overall durability. Pores act as stress concentrators, making the material prone to fracture under load.

How Vacuum Furnaces Solve the Core Problems

A vacuum furnace directly addresses the twin challenges of contamination and porosity, providing an ideal environment for producing high-performance ceramics.

Eliminating Atmospheric Contamination

The most obvious function of the vacuum is to remove reactive gases. By pumping the furnace chamber down to a pressure far below atmospheric, virtually all oxygen, nitrogen, and water vapor are eliminated.

This prevents unwanted chemical reactions, ensuring the final product maintains its intended chemical purity and crystalline structure. This purity is non-negotiable for materials used in aerospace, medical, and semiconductor applications.

Promoting Densification

During sintering, gases can become trapped within the pores of the ceramic structure, preventing the voids from fully closing. A vacuum environment helps extract these trapped gases.

This outgassing process allows the ceramic particles to bond more effectively, significantly reducing residual porosity and enabling the material to reach near-theoretical density.

Enabling Precise Process Control

Vacuum furnaces provide an exceptionally stable and predictable environment. This allows for precise control over the entire heating and cooling cycle.

Some advanced systems, known as vacuum hot press furnaces, add high pressure to the vacuum and high-temperature environment. This mechanical pressure actively compacts the material, further aiding the densification process for producing the highest-quality components.

Understanding the Trade-offs: Vacuum vs. Other Furnaces

The decision to use a vacuum furnace becomes clearer when compared to other thermal processing technologies.

Muffle Furnaces

These are the workhorses of general-purpose laboratory heating. While excellent for many applications in a standard air atmosphere, they offer no protection against oxidation for reactive materials at high temperatures.

Atmosphere Furnaces

An atmosphere furnace is a significant step up, allowing for the introduction of an inert gas (like argon or nitrogen) to displace oxygen. This provides good protection against oxidation.

However, it is difficult to achieve the level of purity that a high vacuum can provide. Trace amounts of reactive gases will always remain, which can be unacceptable for the most sensitive advanced materials.

Vacuum Furnaces

A vacuum furnace offers the ultimate level of atmospheric control. It is the definitive choice when the goal is to achieve the highest possible purity, lowest porosity, and maximum mechanical performance from a material.

Making the Right Choice for Your Goal

Your choice of furnace technology must align directly with the required purity and final density of your material.

- If your primary focus is general heat treatment of non-reactive materials: A standard muffle furnace is often sufficient and more cost-effective.

- If your primary focus is preventing basic oxidation with moderate purity needs: An atmosphere furnace using an inert gas provides a good balance of control and cost.

- If your primary focus is achieving maximum density, purity, and mechanical strength for advanced ceramics (like SiC or Si₃N₄): A vacuum furnace is the essential and non-negotiable tool.

Ultimately, leveraging a vacuum furnace is a strategic decision to control the material's microstructure at the most fundamental level, unlocking its highest potential performance.

Summary Table:

| Aspect | Contribution of Vacuum Furnaces |

|---|---|

| Contamination Control | Removes reactive gases to prevent oxidation and ensure high chemical purity. |

| Densification | Promotes outgassing and particle bonding for near-theoretical density. |

| Process Control | Provides stable, predictable heating/cooling cycles for precise sintering. |

| Performance Outcome | Enables superior mechanical strength, thermal conductivity, and durability. |

Unlock the full potential of your advanced ceramic materials with KINTEK's precision solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with advanced high-temperature furnace options, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements for maximum purity and density. Contact us today to discuss how our tailored furnace technologies can elevate your production process!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine Heated Vacuum Press

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- Why are precision molds and laboratory presses critical for niobium-doped TiO2 ceramics? Achieve 94% Theoretical Density

- What role does a high-performance laboratory hot press machine play in curing? Unlock Superior Composite Strength

- Which process parameters must be optimized for specific materials in a vacuum hot press furnace? Achieve Optimal Density and Microstructure

- What role do a laboratory pressure machine and a steel die-set play in the preparation of Mn2AlB2 compacts?

- What considerations guide the selection of heating elements and pressurization methods for a vacuum hot press furnace?