At its core, vacuum heat treatment is a method of altering a material's properties by heating it within a high-vacuum environment. By pumping nearly all air and reactive gases out of a sealed furnace, the process prevents oxidation, decarburization, and other surface contamination. This results in a cleaner, stronger, and more predictable final product compared to traditional atmospheric heating.

The primary value of vacuum heat treatment is not just the heating itself, but the pristine environment it creates. Removing oxygen and other contaminants allows for metallurgical changes to occur without the interference of unwanted chemical reactions, ensuring the material's surface and structural integrity are preserved.

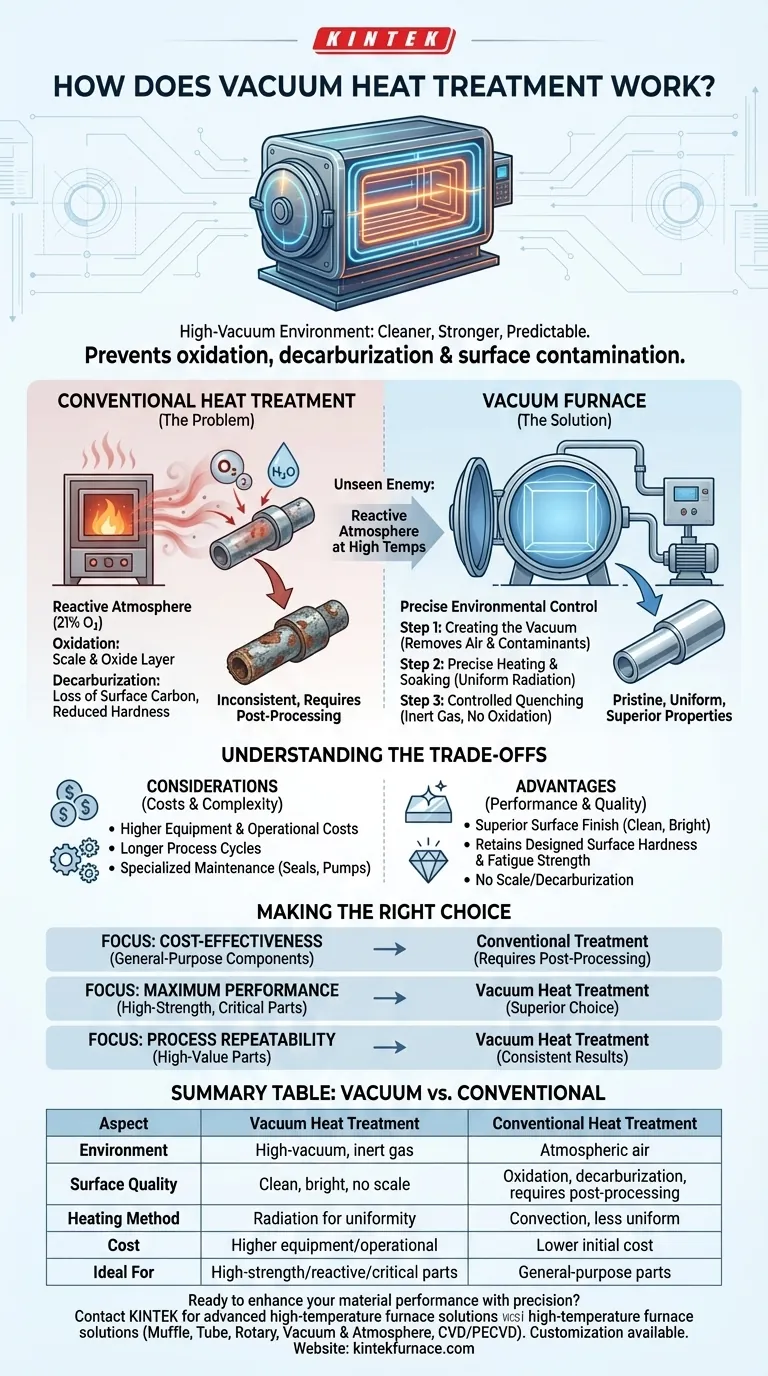

The Problem with Conventional Heat Treatment

To understand the value of a vacuum, we must first recognize the challenges of heating metal in open air. The atmosphere becomes a reactive agent at high temperatures.

The Unseen Enemy: The Atmosphere

The air around us contains approximately 21% oxygen, along with nitrogen, water vapor, and other trace gases. When a metal is heated, its atoms become more energetic and highly susceptible to reacting with these elements.

The Impact of Oxidation and Decarburization

This reaction manifests in two primary ways. Oxidation is the formation of a layer of scale or oxide on the material's surface, which must often be cleaned off later. Decarburization is the loss of carbon from the surface of steel, which reduces its hardness, wear resistance, and fatigue life.

Inconsistent and Unpredictable Results

These unwanted surface reactions can lead to dimensional changes, compromised mechanical properties, and inconsistent results from one batch to the next. This often necessitates additional post-processing steps like grinding, sandblasting, or chemical cleaning to restore the part's required surface finish and dimensions.

How a Vacuum Furnace Solves These Problems

A vacuum furnace is an engineered system designed to precisely control the environment from the beginning of the heating cycle to the end of the cooling cycle.

Step 1: Creating the Controlled Environment

The process begins by placing the material inside a sealed furnace chamber. A powerful system of vacuum pumps then removes the air, lowering the internal pressure to a near-perfect vacuum. This step removes the oxygen, water vapor, and other contaminants that would otherwise react with the hot metal.

Step 2: Precise Heating and Soaking

Once the vacuum is established, heating elements bring the material to its target temperature. In a vacuum, heat is transferred primarily through radiation, which provides extremely uniform heating across the entire part, minimizing thermal stress. The material is held, or "soaked," at this temperature to allow the desired metallurgical transformation to occur throughout its structure.

Step 3: Controlled Quenching

Quenching, or rapid cooling, is what locks in the desired properties like hardness. In a vacuum furnace, this is not done by exposing the part to air. Instead, the chamber is rapidly backfilled with a high-pressure, inert gas like nitrogen or argon. This gas cools the part quickly and uniformly without causing any surface oxidation. Some furnaces also use an integrated, sealed oil quench bath for specific applications.

Understanding the Trade-offs and Considerations

While powerful, vacuum heat treatment is not a universal solution. It involves specific trade-offs that make it ideal for some applications but less practical for others.

Higher Equipment and Operational Costs

Vacuum furnaces represent a significantly larger capital investment than conventional atmospheric furnaces. The process cycles can also be longer due to the time required to pump the chamber down to the target vacuum level, impacting overall throughput.

Maintenance Complexity

Maintaining a perfect seal and a high-performance vacuum system is critical. This requires specialized knowledge and regular maintenance of pumps, chamber seals, and diagnostic instrumentation to prevent leaks that would compromise the entire process.

Superior Surface Finish and Properties

The definitive advantage is the result: parts emerge from the furnace clean, bright, and free of scale. By preventing decarburization, the material retains its designed surface hardness and fatigue strength, which is critical for high-performance components.

Making the Right Choice for Your Goal

Selecting between vacuum and atmospheric heat treatment depends entirely on your material requirements, project goals, and budget.

- If your primary focus is cost-effectiveness for general-purpose components: Conventional atmospheric treatment is often sufficient, provided you can accommodate post-processing like sandblasting or grinding.

- If your primary focus is maximum performance and material integrity: Vacuum heat treatment is the superior choice for high-strength steels, reactive metals (like titanium and superalloys), and critical components where surface quality is paramount.

- If your primary focus is process repeatability for high-value parts: The high degree of automation and control in vacuum furnaces delivers exceptionally consistent metallurgical results from batch to batch.

Ultimately, investing in a vacuum process is an investment in unparalleled control over the final metallurgical outcome.

Summary Table:

| Aspect | Vacuum Heat Treatment | Conventional Heat Treatment |

|---|---|---|

| Environment | High-vacuum, inert gas | Atmospheric air |

| Surface Quality | Clean, bright, no scale | Oxidation, decarburization, requires post-processing |

| Heating Method | Radiation for uniformity | Convection, less uniform |

| Cost | Higher equipment and operational costs | Lower initial cost |

| Ideal For | High-strength steels, reactive metals, critical parts | General-purpose components with post-processing |

Ready to enhance your material performance with precision? Contact KINTEK today to explore our advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we offer Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Get in touch now for a tailored solution that ensures cleaner, stronger, and more predictable results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today