In short, vacuum heat treatment enhances product quality by creating a pristine, highly controlled environment that is impossible to achieve in open air. This process prevents surface damage like oxidation, ensures uniform heating to minimize internal stress, and even purifies the metal by removing trapped gases, resulting in components with superior finish, strength, and reliability.

The core value of vacuum heat treatment is not merely heating a part, but fundamentally improving its material properties. By eliminating unwanted chemical reactions and thermal gradients, the process delivers a final product that is cleaner, stronger, and more dimensionally accurate than what traditional methods can produce.

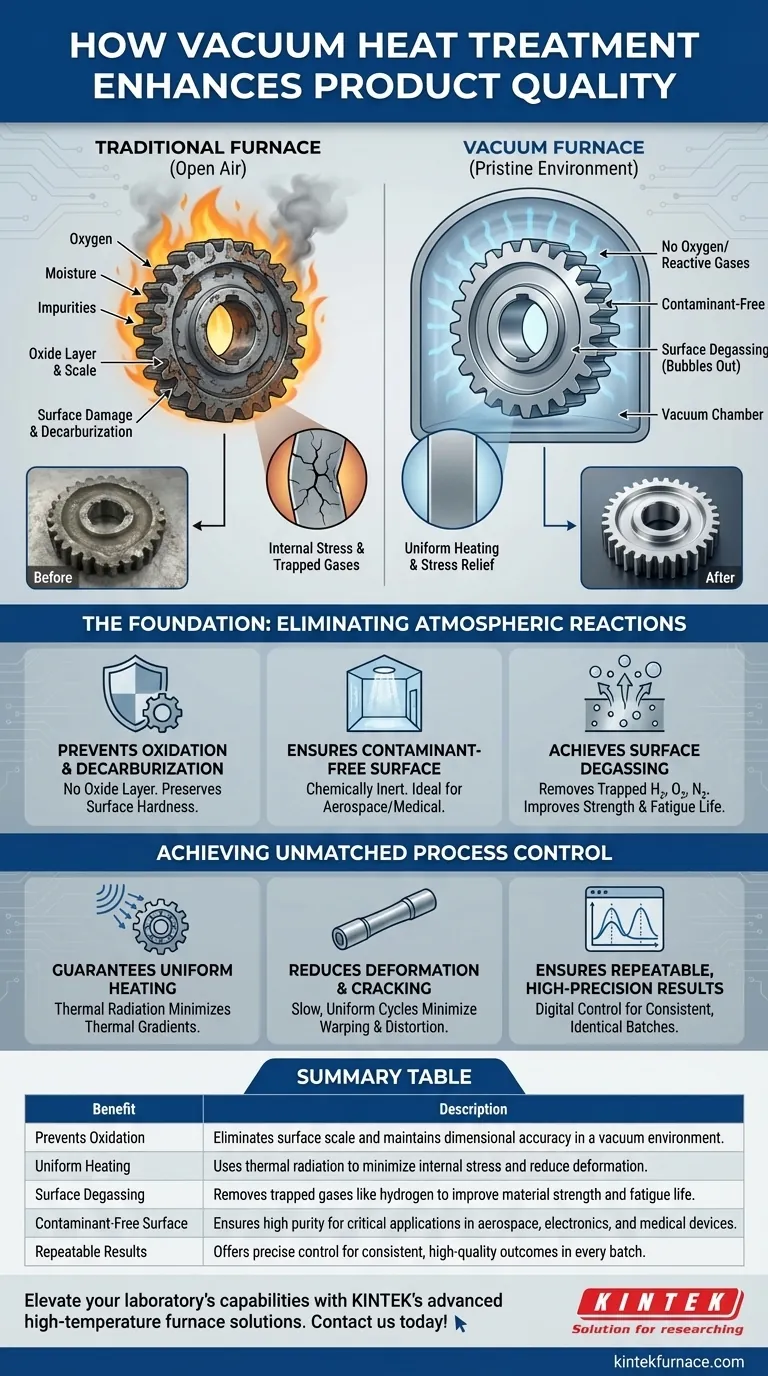

The Foundation: Eliminating Atmospheric Reactions

The primary advantage of a vacuum furnace is the removal of air and other reactive gases. This fundamentally changes the outcome of the heat treatment process.

Preventing Oxidation and Decarburization

In traditional furnaces, the oxygen in the air reacts with the hot metal surface, forming a dark, flaky layer of scale known as an oxide layer. This damages the part in several ways.

Oxidation causes a loss of metallic luster, increases surface roughness, and reduces the dimensional precision of the component. A vacuum environment prevents any contact with oxygen, ensuring the part emerges with a bright, clean surface that often requires no post-process cleaning or machining.

Similarly, a vacuum prevents decarburization—the loss of carbon from the surface of steel alloys—which preserves the designed hardness and wear resistance of the material.

Ensuring a Contaminant-Free Surface

Beyond oxygen, the atmosphere contains moisture and other impurities that can contaminate the workpiece. A vacuum furnace creates a chemically inert environment.

This is critical for high-purity materials used in aerospace, electronics, and medical devices, where even minor surface contamination can compromise performance. The result is a component with enhanced mechanical, thermal, and electrical properties.

Achieving Surface Degassing

A vacuum doesn't just prevent gases from getting in; it actively pulls dissolved gases out of the metal itself.

Elements like hydrogen, oxygen, and nitrogen trapped within the material's structure can cause brittleness or lead to defects. The vacuum environment effectively "boils" these gases out, improving the material's overall plasticity, strength, and fatigue life.

Achieving Unmatched Process Control

Beyond creating a clean environment, vacuum furnaces offer a superior level of control over the thermal cycle, which is essential for consistent, high-quality results.

Guaranteeing Uniform Heating

At high temperatures in a vacuum, heat is transferred primarily through thermal radiation. While slower than convection in air, this method is significantly more uniform.

Every part of the workpiece, regardless of its geometry, heats up at a very even rate. This minimizes thermal gradients and the internal stresses they create.

Reducing Deformation and Cracking

The slow, uniform heating and cooling cycles possible in a vacuum furnace drastically reduce thermal stress.

This is the key to minimizing warping, distortion, and cracking, especially in parts with complex shapes or thin sections. The finished product maintains its intended geometry with much higher fidelity.

Ensuring Repeatable, High-Precision Results

Modern vacuum furnaces, often paired with precision chillers, offer digital control over temperature and pressure. This ensures that every batch is treated with an identical thermal profile.

This high degree of repeatability is vital for industries where parts must meet strict specifications every time, eliminating the batch-to-batch variations common with less controlled methods.

Understanding the Trade-offs

While its benefits are significant, vacuum heat treatment is not a universal solution. It involves specific considerations that make it ideal for some applications but less practical for others.

Slower Cycle Times

The reliance on radiant heating, which provides exceptional uniformity, also means that cycle times are generally longer than in conventional atmosphere furnaces. This can be a limiting factor for very high-volume, low-cost production where throughput is the primary driver.

Higher Initial Investment

Vacuum furnaces represent a significant capital investment compared to traditional equipment. The cost is weighed against the benefits of higher quality, reduced post-processing needs, and the elimination of costs associated with flammable or expensive process gases like hydrogen or argon.

Making the Right Choice for Your Application

Selecting vacuum heat treatment is a strategic decision based on the specific quality requirements of your component.

- If your primary focus is surface finish and dimensional accuracy: Vacuum treatment is the superior choice, as it produces a bright, clean part that requires little to no secondary machining or cleaning.

- If your primary focus is mechanical performance and reliability: The degassing and uniform quenching provided by the vacuum process yield superior material strength, toughness, and fatigue life, critical for high-stress applications.

- If your primary focus is process consistency for high-spec parts: The precise, repeatable control of a vacuum furnace ensures that every component meets exact specifications, making it essential for the medical, aerospace, and electronics industries.

Ultimately, adopting vacuum heat treatment is an investment in achieving the highest possible material integrity and performance for your final product.

Summary Table:

| Benefit | Description |

|---|---|

| Prevents Oxidation | Eliminates surface scale and maintains dimensional accuracy in a vacuum environment. |

| Uniform Heating | Uses thermal radiation to minimize internal stress and reduce deformation. |

| Surface Degassing | Removes trapped gases like hydrogen to improve material strength and fatigue life. |

| Contaminant-Free Surface | Ensures high purity for critical applications in aerospace, electronics, and medical devices. |

| Repeatable Results | Offers precise control for consistent, high-quality outcomes in every batch. |

Elevate your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all with deep customization to meet your unique experimental needs. Contact us today to enhance your product quality and achieve superior material performance—get in touch now!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- Where are vacuum furnaces used? Critical Applications in Aerospace, Medical, and Electronics