At its core, vacuum heat treatment is a highly controlled process for altering a metal's physical and chemical properties by heating and cooling it within a near-vacuum environment. Unlike traditional methods that expose hot metal to air, this process removes atmospheric gases to prevent unwanted chemical reactions. This fundamental difference is what allows materials to achieve their maximum performance potential, resulting in components that are stronger, more durable, and have a significantly longer service life.

The crucial insight is that vacuum heat treatment is less about the heat and more about the controlled environment. By eliminating atmospheric contamination like oxygen, the process prevents surface defects, enabling the creation of parts with superior strength, finish, and reliability that is simply unattainable with conventional methods.

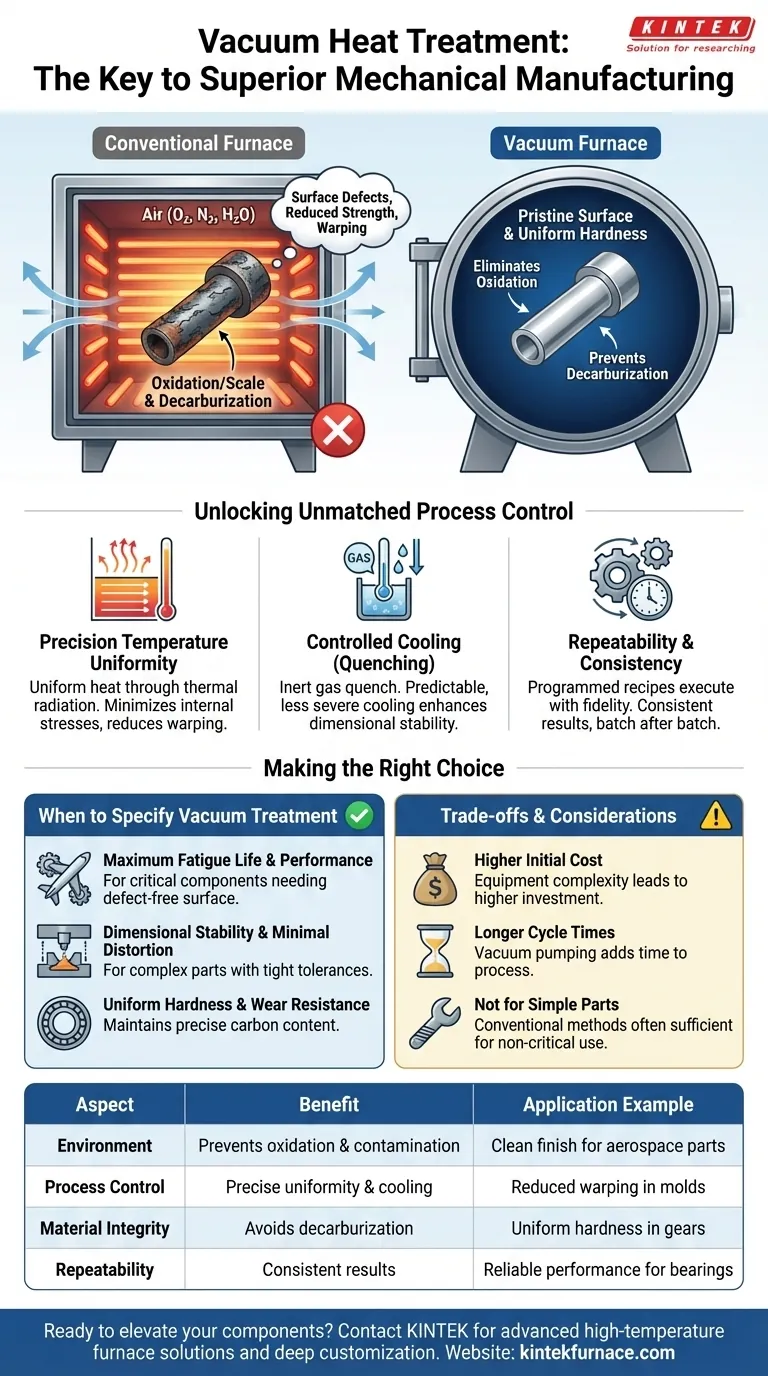

The Core Principle: Why a Vacuum Matters

The primary advantage of performing heat treatment in a vacuum is the elimination of reactive gases. When metals are heated to high temperatures in the presence of air, their surfaces react with oxygen, nitrogen, and water vapor, leading to significant degradation.

Eliminating Oxidation and Surface Contamination

At high temperatures, oxygen aggressively bonds with most metals, forming a brittle, flaky layer of oxide known as scale. This scale not only ruins the part's surface finish but can also hide surface cracks and must be removed through costly secondary operations like grinding or chemical cleaning.

Vacuum heat treatment completely prevents oxidation, resulting in a bright, clean, and smooth surface straight out of the furnace.

Preventing Decarburization

For high-carbon steels used in tools, bearings, and gears, another danger is decarburization. This occurs when oxygen in the atmosphere pulls carbon atoms from the surface of the steel.

Losing surface carbon makes the part softer and drastically reduces its wear resistance and fatigue life. A vacuum environment protects the precise carbon content of the material, ensuring uniform hardness from the core to the surface.

Unlocking Unmatched Process Control

A vacuum is the ideal medium for achieving absolute control over the entire heat treatment cycle. This leads to a level of precision and repeatability that is critical for high-performance applications.

Precision Temperature Uniformity

In a normal furnace, air currents create hot and cold spots, causing uneven heating. In a vacuum, heat is transferred primarily through thermal radiation, which is far more uniform.

This ensures the entire part, regardless of its complex geometry, reaches the target temperature at the same time. This minimizes internal stresses, reducing the risk of warping and distortion.

Controlled Cooling (Quenching)

The cooling phase, or quenching, is just as critical as heating for determining a part's final hardness. Vacuum furnaces allow for highly controlled quenching by backfilling the chamber with a precise pressure of inert gas, like nitrogen or argon.

This method provides a much more predictable and less severe quench than plunging a hot part into oil or water, further enhancing dimensional stability.

Repeatability and Consistency

By removing the unpredictable variables of atmospheric chemistry, a vacuum furnace can execute a programmed heating and cooling recipe with exceptional fidelity. This ensures that every part in a batch—and every batch over time—receives the exact same treatment, leading to highly consistent and reliable final products.

Understanding the Trade-offs

While powerful, vacuum heat treatment is not the solution for every application. Its benefits come with practical considerations that must be weighed against the project's requirements.

Higher Initial Cost

Vacuum furnace equipment is significantly more complex and expensive to purchase and maintain than conventional atmospheric furnaces. This cost is ultimately factored into the price of the treatment.

Longer Cycle Times

The process of pumping the chamber down to a deep vacuum and then backfilling it for quenching adds time to the overall cycle. For high-volume, low-spec parts, this can be a bottleneck.

Not a Universal Solution

For simple components where surface finish is not critical and tolerances are loose, the added expense and complexity of vacuum treatment may not be justified. A conventional heat treatment process is often sufficient and more economical for these use cases.

When to Specify Vacuum Heat Treatment

Making the right choice depends entirely on the performance requirements and value of the final component.

- If your primary focus is maximum fatigue life and performance: Specify vacuum treatment for critical components like gears, bearings, and aerospace parts, as the pristine, defect-free surface is non-negotiable for durability.

- If your primary focus is dimensional stability and minimal distortion: Choose vacuum treatment for complex parts with tight tolerances, such as injection molds and precision tooling, where the uniform heating and controlled cooling are paramount.

- If your primary focus is cost-effectiveness for non-critical parts: A conventional atmospheric treatment will likely provide the necessary properties more economically for components where surface oxidation and slight distortion are acceptable.

Ultimately, understanding the unique benefits of a controlled vacuum environment empowers you to make an informed decision that aligns with your engineering goals.

Summary Table:

| Aspect | Benefit |

|---|---|

| Environment | Prevents oxidation and surface contamination, ensuring bright, clean finishes |

| Process Control | Enables precise temperature uniformity and controlled cooling, reducing warping |

| Material Integrity | Avoids decarburization, maintaining uniform hardness and wear resistance |

| Repeatability | Provides consistent results batch after batch for reliable performance |

| Applications | Ideal for critical components like gears, bearings, and aerospace parts |

Ready to elevate your mechanical components with superior vacuum heat treatment? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, delivering enhanced strength, durability, and performance for your critical parts. Contact us today to discuss how our tailored solutions can benefit your projects!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What is the process of vacuum heat treatment? Achieve Superior Metallurgical Properties

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- What is a vacuum furnace used for? Achieve Purity and Precision in High-Temp Processing

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties