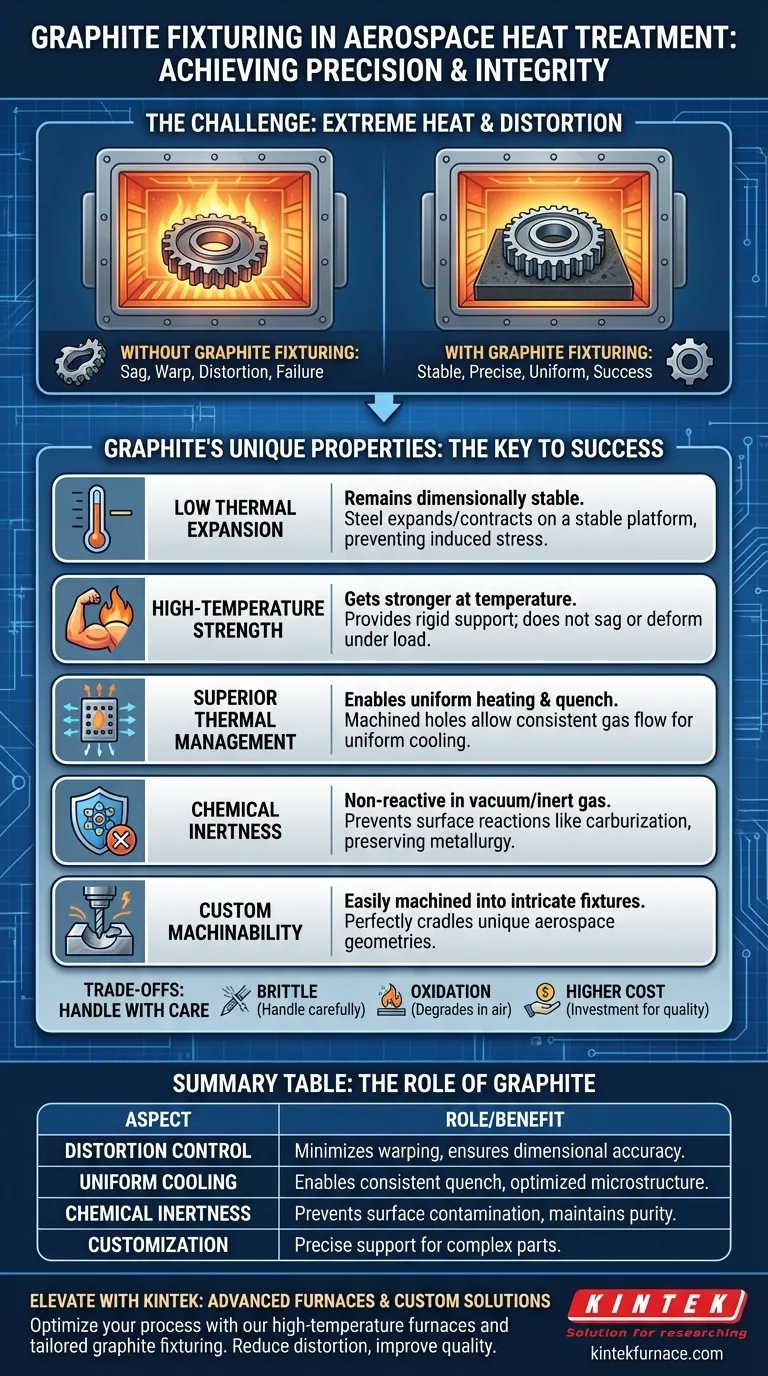

In short, graphite fixturing is used in the heat treatment of steel aerospace components to minimize distortion and ensure uniform cooling. Its unique physical properties make it an ideal material for supporting high-precision parts, like those made from 4340M steel, as they undergo extreme temperature changes in a vacuum furnace environment.

The decision to use graphite is not merely about holding a part in place. It is a strategic choice to control the part's geometry and metallurgy in a high-stakes environment where dimensional accuracy is non-negotiable. Graphite's stability at high temperatures is the key to preventing costly distortion.

Why Distortion Control is Mission-Critical

Heat treatment, by its very nature, is a thermally violent process. For aerospace components, where tolerances are measured in thousandths of an inch, any uncontrolled movement can render a part useless.

The Challenge of High Temperatures

When steel is heated to austenitizing temperatures (well over 800°C), it loses a significant amount of its strength. In this near-plastic state, a component can easily sag, bend, or warp under its own weight if not supported properly.

The Consequence of Warpage

Distortion is not just an inconvenience; it's a critical failure. Warped components may require expensive and time-consuming post-treatment machining to bring them back into tolerance, or worse, they may need to be scrapped entirely, wasting valuable material and manufacturing time.

Graphite's Unique Properties for Heat Treatment

Graphite is chosen because its material properties directly solve the fundamental challenges of heat treating complex steel parts. It stands apart from metallic alloys which would expand, contract, and potentially weld themselves to the component.

Extremely Low Thermal Expansion

This is the single most important property. Graphite has a very low coefficient of thermal expansion (CTE). As the furnace and the component heat up to extreme temperatures, a graphite fixture remains dimensionally stable. The steel part expands and contracts on this stable platform, preventing the fixture itself from inducing stress and distortion.

High-Temperature Strength

Unlike metals, graphite gets stronger as temperature increases, up to a point. It easily maintains its structural integrity and shape at the temperatures required for hardening steel, providing a rigid and reliable support structure that will not sag or deform.

Superior Thermal Management

Graphite has good thermal conductivity, which helps in achieving uniform heating of the component. Furthermore, as noted for 4340M components, fixtures are often machined with holes. These are not random; they are precisely placed to allow quench gas (like nitrogen) to flow uniformly around the part, ensuring a consistent cooling rate. This uniform quench is critical for achieving the desired hardness and microstructure while minimizing thermal-gradient-induced stress and distortion.

Chemical Inertness

In the partial pressure nitrogen or vacuum environments common in aerospace heat treatment, graphite is highly inert. It will not react with the steel's surface, preventing unwanted carburization or decarburization that could compromise the component's metallurgical properties.

Custom Machinability

Graphite is easily machined into intricate shapes. This allows for the creation of custom-designed fixtures that perfectly cradle the unique geometry of a specific aerospace part, providing support exactly where it's needed to fight against gravity and thermal stress.

Understanding the Trade-offs

While graphite is the premium choice, it is essential to understand its limitations to use it effectively.

Brittleness and Handling

Graphite is a brittle material. Fixtures can be easily chipped or broken if mishandled, requiring careful operation and storage protocols. This fragility contrasts with the ductility of metal alloy fixtures.

Lifespan and Oxidation

While robust at temperature in a vacuum or inert gas, graphite will oxidize and degrade if exposed to air at high temperatures. Over many thermal cycles, even in a controlled atmosphere, fixtures can slowly erode, requiring eventual replacement.

Cost

High-purity, high-density isotropic graphite is a significant investment compared to simple steel or ceramic fixtures. The cost is justified by the reduced scrap rate and superior quality of the final components, but it is a factor in process planning.

Making the Right Choice for Your Process

The choice of fixturing material directly impacts the quality and cost-effectiveness of your heat treatment operation.

- If your primary focus is minimal distortion on complex, high-value parts: Graphite is the unmatched solution due to its low CTE and customizability.

- If your primary focus is ensuring uniform metallurgical properties: The thermal management capabilities of a well-designed graphite fixture are essential for a consistent quench.

- If your primary focus is process purity in a vacuum furnace: Graphite's inertness and low outgassing make it the safest choice to protect both the furnace and the component surface.

By choosing graphite fixturing, you are investing in a predictable process that prioritizes the final integrity and precision of the component.

Summary Table:

| Aspect | Role of Graphite Fixturing |

|---|---|

| Distortion Control | Minimizes warping with low thermal expansion and high-temperature strength |

| Uniform Cooling | Enables consistent quench via machined holes for gas flow |

| Chemical Inertness | Prevents surface reactions like carburization in vacuum environments |

| Customization | Allows precise machining for complex part geometries |

Elevate your aerospace heat treatment with KINTEK's advanced solutions! Leveraging exceptional R&D and in-house manufacturing, we provide high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure graphite fixturing and equipment precisely meet your unique experimental needs, reducing distortion and improving part quality. Contact us today to discuss how we can optimize your process!

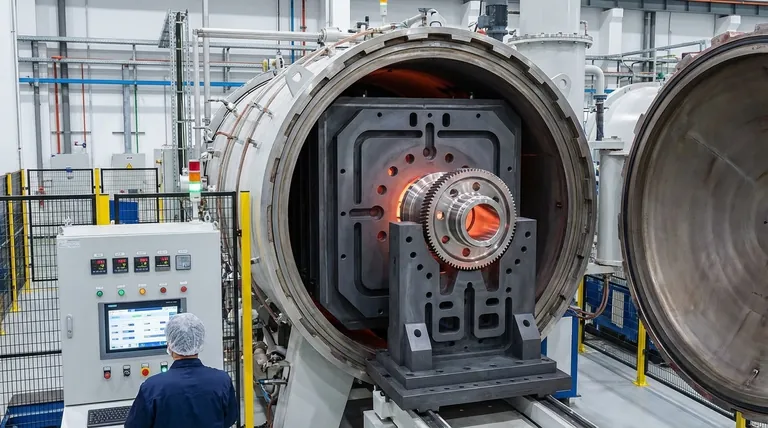

Visual Guide

Related Products

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- Why are graphite fixtures and holders important in vacuum furnaces? Unlock Precision & Durability

- What is the primary function of a vacuum graphite furnace? Achieve Extreme-Temperature Material Purity

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- Why is graphite a preferred material for heating elements in high-temperature vacuum furnaces?

- Why are vacuum furnaces used for the re-quenching of samples after a boriding treatment? Master Core Toughness