At its core, vacuum heat treatment offers unparalleled control over a material's final state. By performing the thermal process in a controlled, atmosphere-free environment, this technology delivers significant advantages over conventional methods, including superior surface quality, enhanced mechanical properties, and exceptional process consistency without the risk of oxidation or contamination.

Conventional heat treatment struggles with unwanted atmospheric reactions that degrade a part's surface and internal structure. Vacuum heat treatment fundamentally solves this by removing the atmosphere, resulting in cleaner, stronger, and more dimensionally stable components directly out of the furnace.

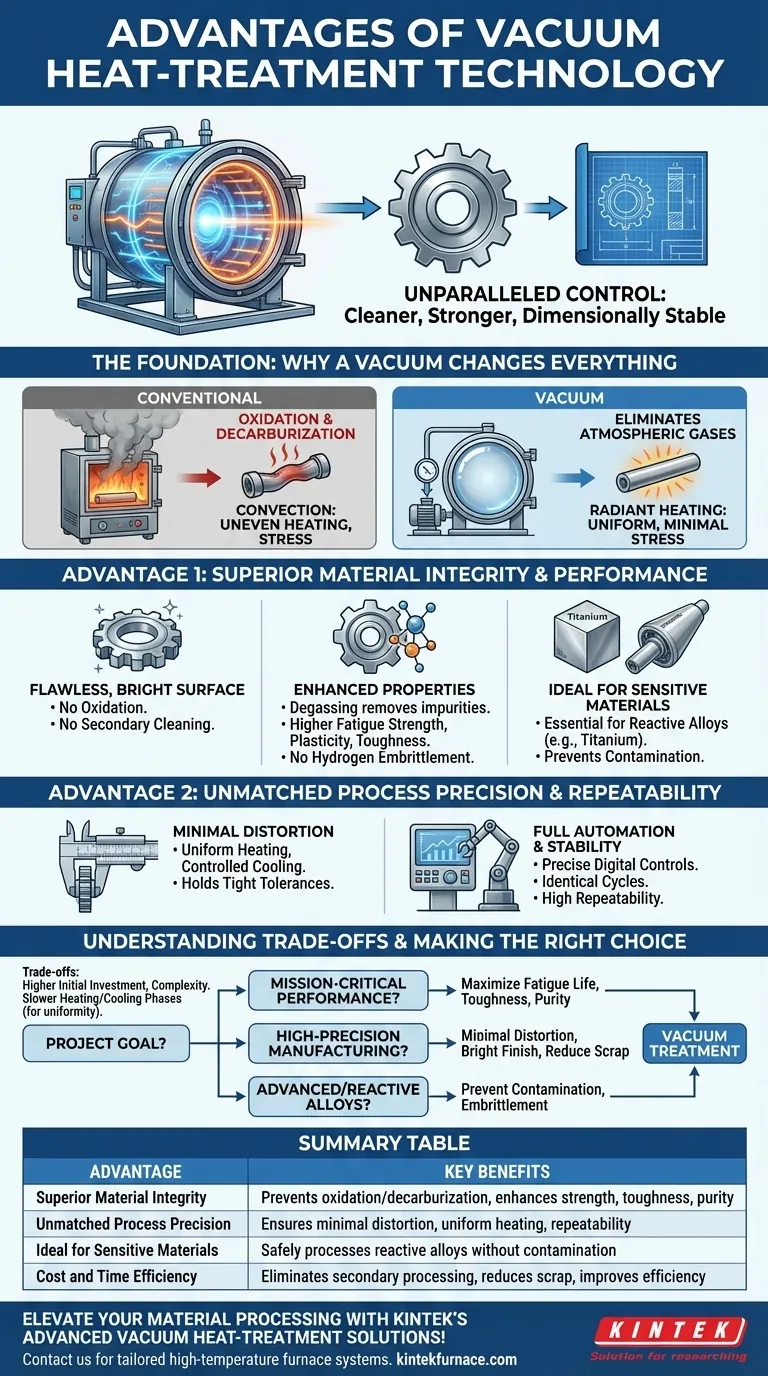

The Foundation: Why a Vacuum Changes Everything

The primary benefit of a vacuum is the elimination of atmospheric gases, particularly oxygen and carbon. This simple change has profound effects on the entire heat treatment process and the final quality of the workpiece.

Eliminating Atmospheric Contamination

In a traditional furnace, high temperatures cause oxygen to react with a metal's surface, creating a layer of scale known as oxidation. It also can lead to decarburization, where carbon is depleted from the surface of steel, making it soft and brittle.

A vacuum environment is devoid of these reactive gases. This completely prevents oxidation and decarburization, preserving the integrity of the material's surface and its chemical composition.

Promoting Uniform Heating

In a vacuum, heat transfer at high temperatures occurs primarily through radiation, not convection. This radiant heat is absorbed more slowly and uniformly across the entire surface of the part, including complex geometries.

This gentle, even heating minimizes thermal stress, which is a primary cause of distortion and warpage. The result is a more dimensionally stable component.

Advantage 1: Superior Material Integrity and Performance

By controlling the environment, vacuum heat treatment directly improves the physical and mechanical properties of the workpiece.

A Flawless, Bright Surface

Because no oxidation occurs, parts emerge from a vacuum furnace with a clean, bright surface finish. This often eliminates the need for costly and time-consuming secondary operations like sandblasting, grinding, or chemical cleaning.

Enhanced Mechanical Properties

The vacuum actively pulls trapped gases, like hydrogen and oxygen, out of the metal in a process called degassing. Removing these impurities significantly improves the material's purity.

This leads to enhanced fatigue strength, plasticity, and toughness. It also eliminates the risk of hydrogen embrittlement, a critical failure mechanism in high-strength steels.

Ideal for Sensitive Materials

Reactive materials like titanium alloys and refractory metals are extremely susceptible to contamination from atmospheric gases. Vacuum heat treatment is often the only viable method to process these advanced materials without causing surface embrittlement. This is critical for applications in aerospace and medical implants.

Advantage 2: Unmatched Process Precision and Repeatability

The controlled nature of a vacuum furnace translates into a highly predictable and reliable manufacturing process.

Minimal Distortion

The combination of uniform heating and controlled cooling cycles drastically reduces internal stresses. This results in minimal distortion, allowing for the production of high-precision parts that hold tight tolerances without corrective machining.

Full Automation and Stability

Modern vacuum furnaces are highly automated systems. Precise digital controls over temperature, vacuum levels, and quenching cycles ensure that every process is executed identically.

This guarantees exceptional process stability and repeatability, which is essential for quality control in high-volume production and mission-critical applications.

Understanding the Trade-offs

While powerful, vacuum heat treatment is not a universal solution. Understanding its limitations is key to making an informed decision.

Initial Investment and Complexity

Vacuum furnaces are sophisticated pieces of equipment that represent a higher initial capital investment compared to conventional atmospheric furnaces. Their operation and maintenance require specialized knowledge of vacuum systems, including pumps, seals, and instrumentation.

Cycle Time Considerations

While the overall process can be faster by eliminating post-processing, the heating and cooling phases within a vacuum can be slower than in conventional furnaces. This is a deliberate trade-off to ensure thermal uniformity and minimize stress, but it can impact throughput for certain applications.

Making the Right Choice for Your Goal

Selecting the right heat treatment method depends entirely on your project's specific requirements for quality, performance, and material type.

- If your primary focus is mission-critical component performance: Vacuum treatment is the superior choice for maximizing fatigue life, toughness, and material purity.

- If your primary focus is high-precision manufacturing: The minimal distortion and bright finish provided by vacuum technology will reduce scrap and eliminate secondary processing steps.

- If your primary focus is working with advanced or reactive alloys: Vacuum treatment is essential to prevent surface contamination and embrittlement for materials like titanium and specialized steels.

Ultimately, adopting vacuum heat treatment is a strategic decision to prioritize the quality, consistency, and ultimate performance of your final product.

Summary Table:

| Advantage | Key Benefits |

|---|---|

| Superior Material Integrity | Prevents oxidation and decarburization, enhances fatigue strength, toughness, and purity through degassing |

| Unmatched Process Precision | Ensures minimal distortion, uniform heating, and repeatability for high-precision components |

| Ideal for Sensitive Materials | Safely processes reactive alloys like titanium without contamination, crucial for aerospace and medical applications |

| Cost and Time Efficiency | Eliminates secondary processing, reduces scrap, and improves overall manufacturing efficiency |

Elevate your material processing with KINTEK's advanced vacuum heat-treatment solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, delivering superior performance, consistency, and cost savings. Don't let contamination or distortion hold you back—contact us today to discuss how our tailored solutions can optimize your processes and achieve unparalleled results for your high-precision and reactive material applications!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance