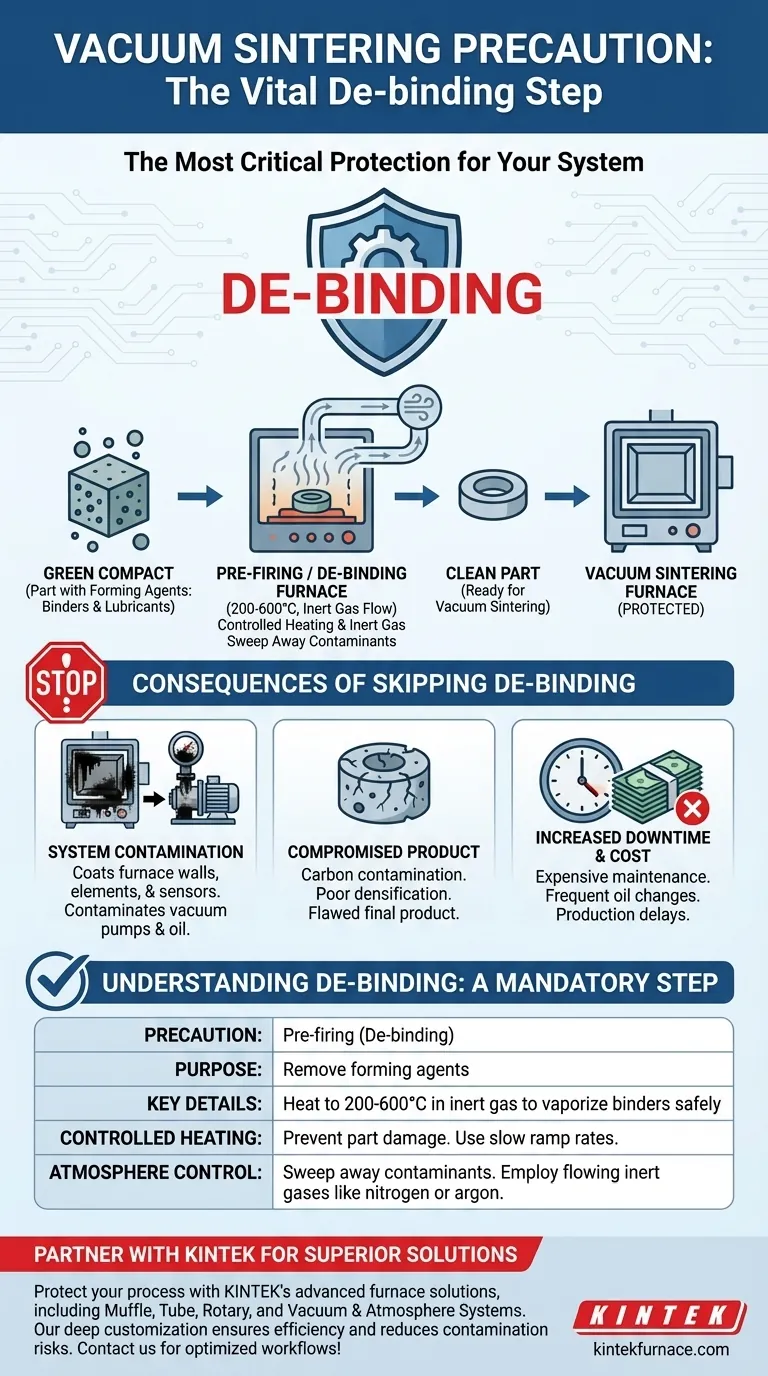

The most critical precaution to protect a vacuum system before sintering is to perform a separate pre-firing or "de-binding" step on the compacted part, known as a briquette or green compact. This preliminary heating cycle is designed specifically to remove binders, lubricants, and other forming agents added to the metal powder. Failing to do this will lead to severe contamination of the furnace and vacuum pumps.

The core issue is that forming agents required to shape the part will vaporize under heat and vacuum, contaminating every surface they touch. This compromises the final product, damages expensive equipment, and creates significant operational downtime. Pre-firing is not an optional shortcut; it is a mandatory process step for successful vacuum sintering.

The Role of Forming Agents

Forming agents are essential in powder metallurgy to create a handleable part from loose powder, but they become a significant liability inside a vacuum furnace.

What Are Forming Agents?

Forming agents are organic additives mixed with metal powder before it is pressed into a shape. These can include paraffin wax, polyethylene glycol (PEG), or other polymers.

Their purpose is to act as a binder and lubricant. The binder provides "green strength," allowing the pressed part (the green compact) to be handled and moved without crumbling before it is sintered.

The Problem Under Vacuum and Heat

When a green compact containing these agents is heated in a vacuum, the organic compounds do not burn away cleanly as they would in open air.

Instead, they pyrolyze and vaporize, a process known as outgassing. This releases large volumes of hydrocarbon gases directly into the furnace chamber.

Consequences of Ignoring Pre-Firing

Skipping the de-binding step has severe and costly consequences for both the equipment and the product.

Contamination of the Vacuum System

The vaporized forming agents will travel throughout the vacuum system and condense on any cooler surface.

This contamination coats the furnace's internal walls, heating elements, and insulation. It also gets drawn into the vacuum pumps, contaminating expensive pump oil and degrading pump performance. Vacuum sensors and gauges become coated and provide false readings, leading to a complete loss of process control.

Compromised Product Quality

The contamination doesn't just affect the furnace; it also ruins the parts being sintered. Hydrocarbon vapors can re-deposit onto the part surfaces.

This can lead to unacceptable levels of carbon contamination in the final material, altering its metallurgical properties. It can also interfere with the sintering process itself, resulting in poor densification, increased porosity, and a flawed final product.

Increased Downtime and Maintenance Costs

A contaminated furnace is an offline furnace. Cleaning the condensed binders from the chamber walls and components is a difficult, time-consuming, and expensive manual process.

Vacuum pump oil must be changed frequently, and in severe cases, the pumps may require a complete teardown and rebuild. These maintenance burdens lead to significant production delays and operational costs.

Understanding the Pre-Firing (De-binding) Process

Pre-firing, or de-binding, is a controlled heating cycle designed specifically to remove forming agents before the part enters the vacuum furnace.

How De-binding Works

The green compacts are heated to a relatively low temperature (e.g., 200–600°C) in a separate, dedicated furnace or in a vacuum furnace running a specific pre-sintering recipe.

Crucially, this is often done not under a deep vacuum but in a flowing inert gas atmosphere, such as nitrogen or argon. This flowing gas acts as a carrier, sweeping the vaporized binders out of the furnace through an exhaust system, preventing them from contaminating the chamber or pumps.

Key De-binding Parameters

The success of de-binding depends on controlling the temperature ramp rate and atmosphere. Heating too quickly can cause the part to crack or blister as the binders vaporize internally.

The ideal temperature profile is determined by the specific type and amount of forming agent used. The goal is to hold the part at a temperature that ensures complete removal of the binder without initiating the sintering process.

Making the Right Choice for Your Process

Implementing a robust de-binding protocol is non-negotiable for achieving reliable and high-quality vacuum sintering results.

- If your primary focus is process development: Use methods like Thermogravimetric Analysis (TGA) to precisely identify the vaporization temperature of your forming agents and design an optimized de-binding cycle.

- If your primary focus is production consistency: Implement strict quality control to ensure that every batch of parts completes the validated de-binding cycle before ever entering the expensive vacuum sintering furnace.

- If you suspect your system is already contaminated: Immediately schedule a maintenance cycle to perform a high-temperature "burnout" of the furnace chamber and inspect your vacuum pump oil for discoloration and breakdown.

Protecting your vacuum system begins long before you pull the final vacuum.

Summary Table:

| Precaution | Purpose | Key Details |

|---|---|---|

| Pre-firing (De-binding) | Remove forming agents | Heat to 200-600°C in inert gas atmosphere to vaporize binders safely |

| Controlled Heating | Prevent part damage | Use slow ramp rates to avoid cracking or blistering |

| Atmosphere Control | Sweep away contaminants | Employ flowing inert gases like nitrogen or argon for effective removal |

Protect your vacuum sintering process with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise fit for your unique experimental needs, enhancing efficiency and reducing contamination risks. Contact us today to discuss how our tailored solutions can optimize your de-binding and sintering workflows for superior results!

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the purpose of setting a mid-temperature dwell stage? Eliminate Defects in Vacuum Sintering

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment