In short, a vertical vacuum furnace handles long or large loads by lifting them from the bottom into a cylindrical heating chamber. The load is placed on a movable base, or "hearth," which is then raised by a powerful lift system, positioning the workpiece securely within the furnace's hot zone. This bottom-loading design leverages gravity for stability and is fundamentally different from the horizontal entry of conventional furnaces.

A vertical furnace's primary advantage is not just its ability to lift large loads, but its use of a vertical orientation to minimize part distortion, improve temperature uniformity, and enable rapid, integrated quenching—making it a specialized tool for specific part geometries and metallurgical requirements.

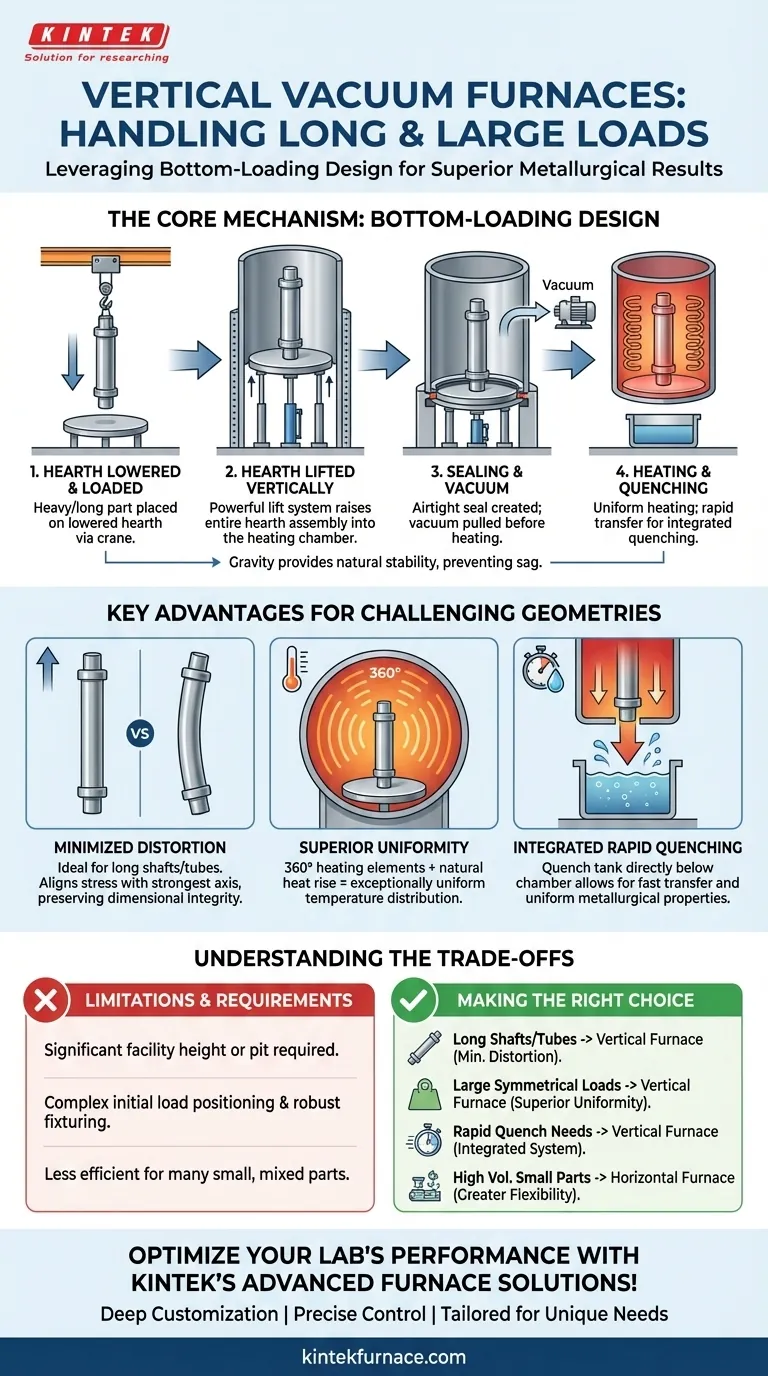

The Core Mechanism: Bottom-Loading Design

To understand how a vertical furnace operates, it's essential to visualize its "bottom-loading" architecture. This design is the key to its ability to process large, heavy, or long components effectively.

How Loading Works

The process begins with the furnace in the open position, where the bottom hearth is lowered to floor level or into a pit. An overhead crane or other material handling equipment is used to place the large workpiece onto the fixture on this hearth.

Once the part is secured, a robust electromechanical or hydraulic lift system raises the entire hearth assembly vertically. It travels up and into the stationary, insulated heating chamber above, which contains the heating elements.

Creating the Vacuum Seal

As the hearth reaches its fully raised position, it engages with a flange on the main chamber. Clamps or locking mechanisms secure it in place, and O-rings or other sealing systems create the airtight seal necessary to pull a vacuum. The heat-treat cycle can only begin after this vacuum integrity is confirmed.

Leveraging Gravity for Stability

Unlike a horizontal furnace where a long part must be supported along its length, a vertical furnace supports the load from its base. Gravity helps keep the component stable and centered, preventing the sagging or distortion that can occur at high temperatures.

Key Advantages for Large Loads

The vertical design offers distinct metallurgical and logistical advantages, especially for components with challenging geometries.

Minimized Distortion

For long, slender parts like shafts, drive-train components, or aircraft landing gear, the risk of bowing or distortion under their own weight in a horizontal furnace is significant. By orienting the part vertically, these gravitational stresses are aligned along the part's strongest axis, preserving its dimensional integrity.

Superior Temperature Uniformity

The cylindrical heating chamber of a vertical furnace allows for the placement of heating elements in a 360-degree arrangement around the load. This configuration, combined with the natural tendency of heat to rise, promotes exceptionally uniform temperature distribution, which is critical for achieving consistent metallurgical properties across a large part.

Integrated and Rapid Quenching

Many vertical furnaces are designed with a quench tank (for oil, water, or polymer) or a high-pressure gas quenching system located directly below the heating chamber. After the heating cycle, the hearth is lowered rapidly, moving the part from the hot zone into the quench medium in seconds. This minimizes transfer time, reduces thermal loss, and ensures a fast, uniform quench.

Understanding the Trade-offs

While powerful, the vertical furnace is not a universal solution. Its design comes with specific limitations that must be considered.

Significant Facility Height Requirements

The most obvious constraint is the need for substantial vertical clearance. The facility must accommodate the full height of the furnace body plus the additional space required to lower the hearth and load/unload the workpiece. This often requires a high-bay facility or the construction of a pit.

Load Handling and Fixturing

While the furnace performs the lift, initially positioning a heavy or awkward part onto the hearth can be more complex than using a charging car for a horizontal furnace. It requires careful planning, overhead crane access, and robust fixturing to ensure the load is stable before it is lifted.

Not Ideal for All Part Mixes

A vertical furnace excels with single large parts or symmetrical loads. It is less efficient for processing many small, flat, or randomly shaped parts that could be easily arranged on multiple stacked trays inside a large-volume horizontal furnace.

Making the Right Choice for Your Application

Selecting the correct furnace type depends entirely on the part geometry, the required metallurgical outcome, and your facility's constraints.

- If your primary focus is minimizing distortion for long shafts, tubes, or gears: The vertical furnace is the definitive choice for maintaining straightness and dimensional accuracy.

- If your primary focus is processing large dies, molds, or symmetrical components requiring the most uniform heating possible: The 360-degree heating of a vertical furnace offers superior temperature control.

- If your primary focus is rapid quenching to achieve specific hardness or microstructure: A bottom-loading vertical furnace with an integrated quench tank provides the fastest and most consistent transfer.

- If your primary focus is processing high volumes of smaller, assorted parts on trays or baskets: A horizontal furnace generally offers greater loading flexibility and efficiency.

By understanding that the vertical furnace's design is purpose-built to control the physics of heat and gravity, you can confidently select the right architecture to protect the value and integrity of your components.

Summary Table:

| Feature | Benefit for Large Loads |

|---|---|

| Bottom-Loading Design | Lifts loads from base for stability and easy handling |

| Vertical Orientation | Reduces part distortion and aligns with gravity |

| Cylindrical Heating Chamber | Ensures 360-degree uniform temperature distribution |

| Integrated Quenching | Allows rapid quenching for consistent metallurgical properties |

| Gravity Leverage | Prevents sagging and improves load security |

Optimize your lab's performance with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored vertical vacuum furnaces, including Muffle, Tube, Rotary, and Atmosphere Furnaces, as well as CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, such as handling long or large loads with minimal distortion and superior temperature control. Contact us today to discuss how we can enhance your metallurgical processes and achieve better results!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does pressure application in a vacuum hot press furnace facilitate sintering of copper composites? Optimize Density

- Why is a vacuum hot press sintering furnace required for nanocrystalline ceramics? Preserve Structure with Pressure

- What is the function of a vacuum sintering furnace in the SAGBD process? Optimize Magnetic Coercivity and Performance

- What are the advantages of a vacuum hot pressing sintering furnace for rare earth copper composites? Density & Purity

- How do vacuum sintering and annealing furnaces contribute to the densification of NdFeB magnets?