A vacuum impregnation device operates by mechanically extracting air and moisture from the micron-sized pores of biomimetic templates, such as silicon carbide or carbon skeletons. By creating a negative pressure environment, the device utilizes a combination of capillary pressure and atmospheric pressure to force molten phase change materials (PCMs) deep into the interconnected pore structure.

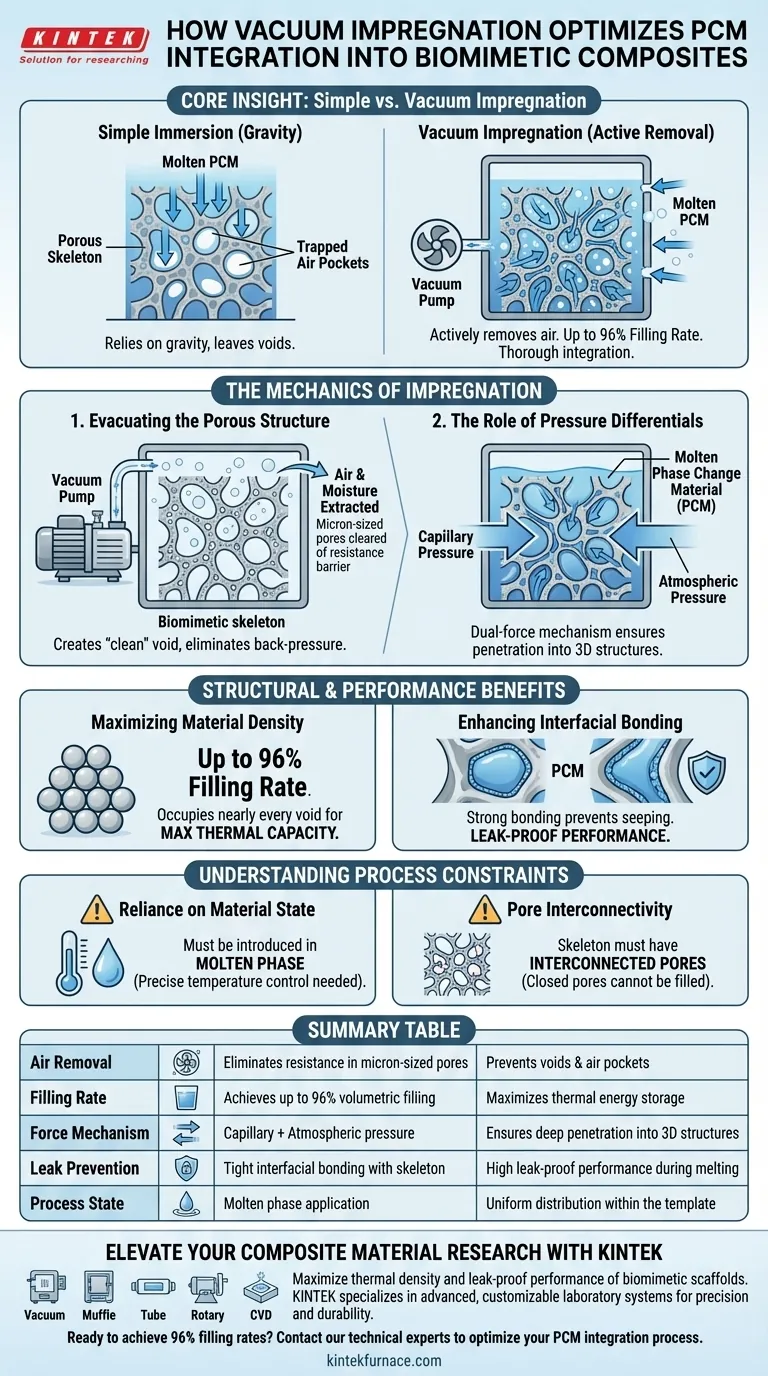

Core Insight: While simple immersion relies on gravity and often leaves trapped air pockets, vacuum impregnation actively removes these barriers. This process achieves filling rates as high as 96%, ensuring the PCM is not just sitting on the surface but is thoroughly integrated into the skeleton for superior leak-proof performance.

The Mechanics of Impregnation

Evacuating the Porous Structure

The primary function of the device is to prepare the host material. Using a vacuum pump, the device extracts air and residual moisture trapped within the micron-sized pores of the biomimetic skeleton.

Removing these gases is critical because trapped air acts as a resistance barrier. By eliminating this back-pressure, the device creates a "clean" void ready to accept the new material.

The Role of Pressure Differentials

Once the air is evacuated, the system utilizes negative pressure to facilitate the flow of the Phase Change Material.

The PCM, maintained in a molten state, is driven into the skeleton by two forces: the natural capillary pressure of the pores and the external push of atmospheric pressure. This dual-force mechanism ensures the liquid penetrates even the deepest sections of the three-dimensional structure.

Structural and Performance Benefits

Maximizing Material Density

The most significant advantage of this method is the filling rate, which can reach up to 96 percent.

Because the pores are thoroughly evacuated before filling, the PCM occupies nearly every available void. This high density is essential for maximizing the thermal energy storage capacity of the final composite.

Enhancing Interfacial Bonding

Vacuum impregnation does more than just fill space; it improves the physical connection between materials.

The process ensures a tight contact between the PCM and the skeletal walls. This strong bonding significantly enhances the leak-proof performance of the composite, preventing the PCM from seeping out during phase transitions (melting).

Understanding Process Constraints

Reliance on Material State

For this process to work, the PCM must be introduced in a molten phase.

This requires precise temperature control during the impregnation process to ensure the material remains fluid enough to permeate the micron-sized pores without premature solidification.

Pore Interconnectivity

The efficiency of the vacuum drive relies on the skeleton having interconnected three-dimensional pores.

If the biomimetic template contains closed-off pores, the vacuum cannot extract the air from those specific sections, and the atmospheric pressure cannot force the PCM inside, regardless of the vacuum strength.

Optimizing Composite Fabrication

When integrating PCMs into biomimetic scaffolds, the choice of impregnation method dictates the final quality of the material.

- If your primary focus is thermal capacity: Vacuum impregnation is essential to achieve the near-total (96%) filling rates required for maximum energy storage.

- If your primary focus is durability: The enhanced bonding provided by vacuum pressure is the best way to ensure leak-proof performance over repeated thermal cycles.

By removing the resistance of air and leveraging pressure differentials, vacuum impregnation transforms a porous skeleton into a solid, high-performance composite.

Summary Table:

| Feature | Vacuum Impregnation Benefit | Impact on Composite |

|---|---|---|

| Air Removal | Eliminates resistance in micron-sized pores | Prevents voids and air pockets |

| Filling Rate | Achieves up to 96% volumetric filling | Maximizes thermal energy storage |

| Force Mechanism | Capillary + Atmospheric pressure | Ensures deep penetration into 3D structures |

| Leak Prevention | Tight interfacial bonding with skeleton | High leak-proof performance during melting |

| Process State | Molten phase application | Uniform distribution within the template |

Elevate Your Composite Material Research with KINTEK

Maximize the thermal density and leak-proof performance of your biomimetic scaffolds. At KINTEK, we specialize in the engineering of advanced laboratory systems designed for precision and durability. Backed by expert R&D and manufacturing, we offer high-performance Vacuum, Muffle, Tube, Rotary, and CVD systems, all fully customizable to meet your unique materials science needs.

Ready to achieve 96% filling rates and superior interfacial bonding in your lab? Contact our technical experts today to discuss how our custom furnace and vacuum solutions can optimize your PCM integration process.

Visual Guide

References

- Min Yu, Dou Zhang. Review of Bioinspired Composites for Thermal Energy Storage: Preparation, Microstructures and Properties. DOI: 10.3390/jcs9010041

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What are the benefits of using a vacuum atmosphere in metal melting? Achieve Ultimate Purity and Control

- What is the function of a laboratory vacuum drying oven in W-Ni2P@NiFe LDH/NF preparation? Optimize Electrocatalysts

- What is the primary function of a vacuum furnace? Achieve Purity and Precision in Heat Treatment

- What is vacuum heat treatment and why is it important in mechanical manufacturing? Boost Component Performance and Lifespan

- What is the primary purpose of using a vacuum drying oven to treat master alloy powders? Ensure Purity & Prevent Oxidation

- How does a high vacuum drying system facilitate the drying of MgAlhfip? Ensure Purity for Magnesium Electrolytes

- How is the furnace body of a vacuum furnace constructed? Explore Its Reinforced, Sealed Design for Extreme Conditions

- In which industries is vacuum brazing commonly applied? Essential for Aerospace, Medical, Automotive, and Electronics