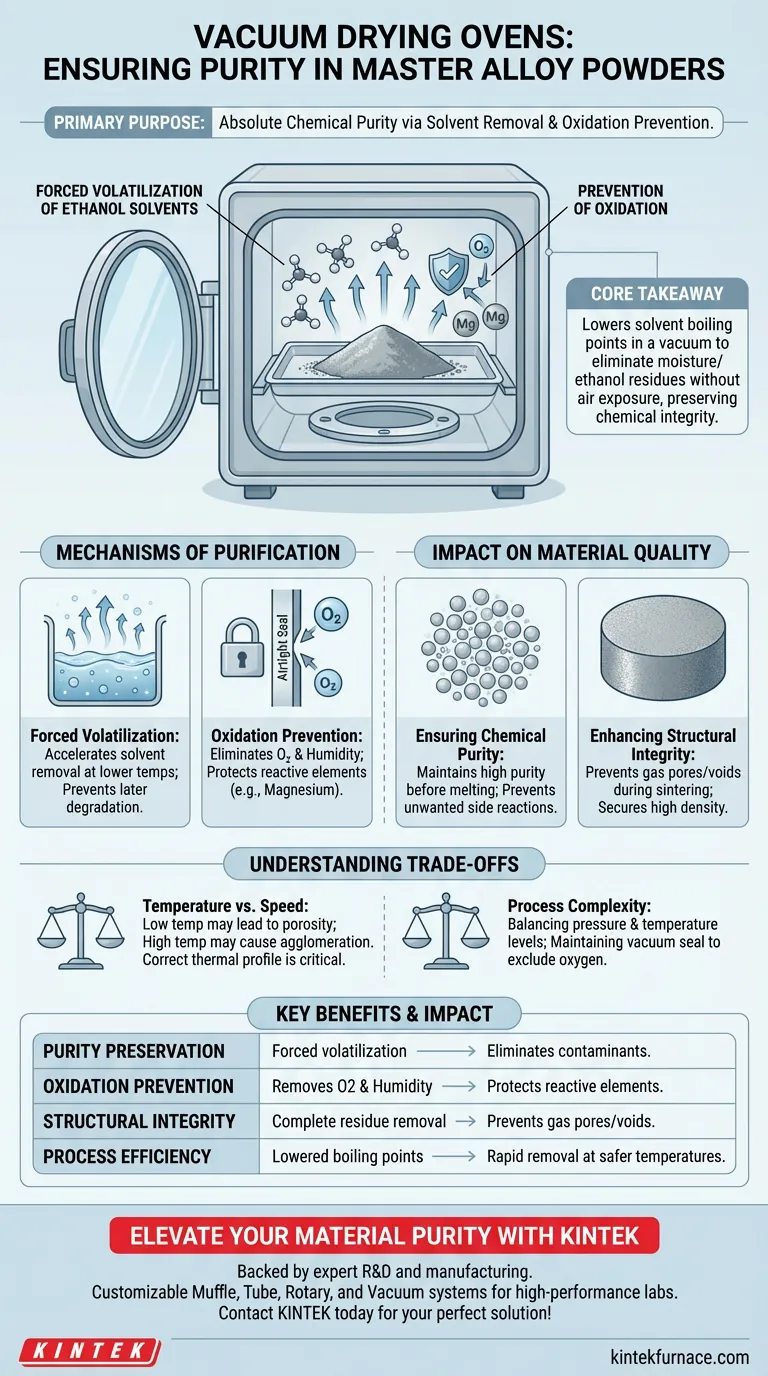

The primary purpose of a vacuum drying oven in treating master alloy powders is to ensure absolute chemical purity by removing solvents while preventing oxidation. Specifically, it facilitates the forced volatilization of ethanol solvents used during processing, operating within a controlled low-pressure and high-temperature environment. This apparatus is essential for protecting reactive components, such as magnesium, from oxidizing when exposed to humidity or oxygen, ensuring the raw material remains pure prior to the melting stage.

Core Takeaway By lowering the boiling point of solvents through reduced pressure, vacuum drying ovens eliminate moisture and ethanol residues without exposing the powder to reactive air. This ensures the master alloy retains its chemical integrity and prevents structural defects like porosity during subsequent processing.

Mechanisms of Purification and Protection

Forced Volatilization of Solvents

The vacuum environment significantly lowers the boiling point of liquids. This allows for the forced volatilization of ethanol solvents and moisture at manageable temperatures.

By accelerating evaporation, the oven ensures that process control agents (like anhydrous ethanol) are completely removed. This is critical because residual solvents can degrade the material quality during later heating stages.

Prevention of Oxidation

Master alloy powders, particularly those containing magnesium, are highly susceptible to oxidation. Standard drying in air would lead to rapid degradation of the material.

The vacuum drying oven eliminates atmospheric oxygen and humidity from the chamber. This creates a protective environment where the powder can dry thoroughly without chemically reacting with the air.

Impact on Material Quality

Ensuring Chemical Purity

The ultimate goal of this pre-treatment is to maintain extremely high chemical purity before the alloy enters the melting stage.

Contaminants or oxides introduced during drying would compromise the alloy's composition. Vacuum drying preserves the active material surface, preventing unwanted side reactions.

Enhancing Structural Integrity

Removing volatile residues prevents the formation of gas pores during sintering or melting. If solvents remain trapped, they evaporate violently at high temperatures, causing voids.

By ensuring a solvent-free powder, the process secures high density and mechanical integrity in the final sample.

Understanding the Trade-offs

Temperature Sensitivity vs. Drying Speed

While vacuum drying allows for lower processing temperatures, selecting the correct thermal profile is still critical.

If the temperature is too low, solvent removal may be incomplete, leading to porosity. If the temperature is too high—even in a vacuum—it may cause phase changes or the agglomeration of fine particles.

Process Complexity

Using a vacuum oven introduces more variables than standard drying, specifically the need to balance pressure levels with temperature.

Operators must ensure the vacuum level is sufficient to lower the solvent boiling point below the material's reactivity threshold. Failure to maintain the vacuum seal introduces oxygen, immediately negating the protective benefits of the process.

Making the Right Choice for Your Goal

To maximize the effectiveness of your vacuum drying process, consider your specific material constraints:

- If your primary focus is Chemical Purity: Prioritize maintaining a deep vacuum to completely exclude oxygen, which is vital for reactive elements like magnesium.

- If your primary focus is Structural Density: Ensure the drying duration is sufficient to remove all trace solvents, preventing pore formation during the melting or sintering phase.

The vacuum drying oven is not just a drying tool; it is a purity preservation system that bridges the gap between raw powder synthesis and high-performance alloy fabrication.

Summary Table:

| Key Benefit | Mechanism | Impact on Master Alloy |

|---|---|---|

| Purity Preservation | Forced volatilization of ethanol | Eliminates contaminants before the melting stage. |

| Oxidation Prevention | Removal of oxygen and humidity | Protects reactive elements like magnesium from degradation. |

| Structural Integrity | Complete removal of volatile residues | Prevents gas pores and voids during sintering or melting. |

| Process Efficiency | Lowered boiling points via vacuum | Allows for rapid solvent removal at safer, lower temperatures. |

Elevate Your Material Purity with KINTEK

Don't let oxidation or residual solvents compromise your master alloy performance. Backed by expert R&D and manufacturing, KINTEK offers customizable Muffle, Tube, Rotary, and Vacuum systems designed to meet the rigorous demands of high-performance lab environments. Whether you are treating reactive powders or developing advanced CVD processes, our precision high-temperature furnaces ensure your materials retain absolute chemical integrity.

Ready to optimize your drying and sintering process? Contact KINTEK today to find the perfect solution for your unique needs!

Visual Guide

References

- Anastasia Akhmadieva, Alexander Vorozhtsov. Structure, Phase Composition, and Mechanical Properties of ZK51A Alloy with AlN Nanoparticles after Heat Treatment. DOI: 10.3390/met14010071

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are the advantages and limitations of using vacuum furnaces? Unlock Precision Heat Treatment

- What are the key components of a vacuum annealing furnace? Master the Core for Superior Material Processing

- What are the steps involved in the vacuum sintering process? Master Precision and Purity for Superior Materials

- What are the benefits of using vacuum furnaces for producing optical materials? Achieve Purity and Performance

- What is the importance of vacuum degassing equipment in gel foaming? Ensure Structural Integrity in Bioceramics

- What are drop-bottom quench furnaces used for? Achieve Rapid Quenching for High-Performance Alloys

- What are the advantages of graphite furnace? Achieve Unmatched High-Temperature Performance

- What types of metals and alloys are suitable for vacuum heat treatment furnaces? Essential Guide for High-Performance Materials