Vacuum degassing equipment acts as a critical quality control gate in the preparation of biomimetic porous ceramics via gel foaming. Its specific role is to forcibly remove entrapped air bubbles from the ceramic slurry before the material is set and fired.

By eliminating micro-bubbles at the slurry stage, vacuum degassing prevents the formation of unintended structural defects during sintering, directly safeguarding the mechanical strength of the final ceramic skeleton.

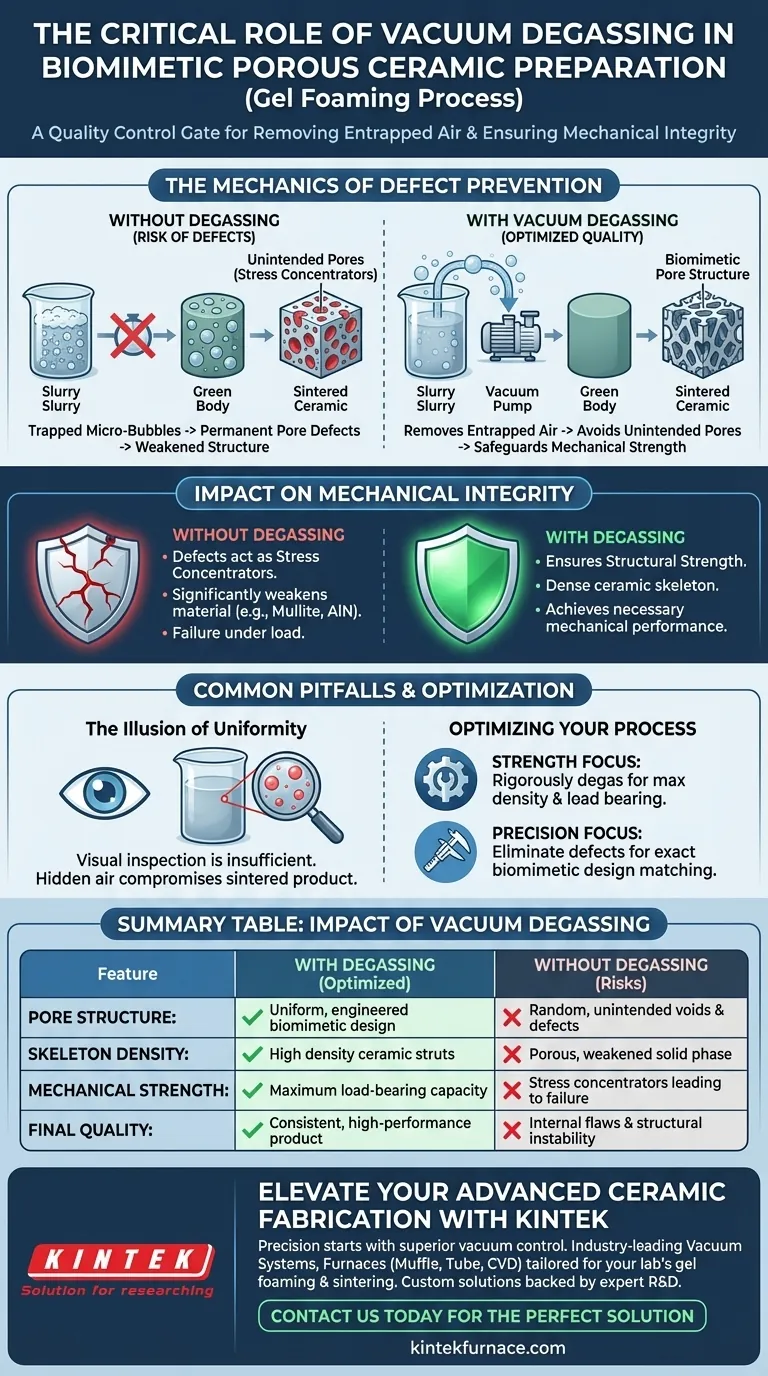

The Mechanics of Defect Prevention

Removing Entrapped Air

During the preparation of ceramic slurries, the mixing process inevitably traps air within the liquid.

Vacuum degassing equipment creates a pressure differential that forces these suspended micro-bubbles to the surface, where they are expelled.

Avoiding Unintended Pores

Biomimetic ceramics rely on a specific, engineered pore structure.

Entrapped air bubbles create random, "unintended" pores that deviate from the design.

Degassing ensures that the only voids present in the material are the ones you deliberately created through the foaming process.

Impact on Mechanical Integrity

The Consequence of Micro-Bubbles

If air bubbles are not removed, they remain trapped as the slurry solidifies.

After the sintering process, these bubbles manifest as permanent pore defects within the ceramic skeleton.

Ensuring Structural Strength

These defects act as stress concentrators, significantly weakening the material.

For high-performance biomimetic structures, such as mullite or aluminum nitride, maintaining the integrity of the solid skeleton is vital.

Degassing ensures the material achieves the necessary mechanical strength to function effectively.

Common Pitfalls to Avoid

The Illusion of Uniformity

A ceramic slurry may appear smooth and uniform to the naked eye even when saturated with micro-bubbles.

Skipping the vacuum degassing step relies on visual inspection, which is insufficient for detecting microscopic trapped air.

Compromising the Sintered Product

Failure to degas creates a trade-off where process speed is prioritized over structural reliability.

While the "green body" (unfired ceramic) may look acceptable, the final sintered product will contain internal flaws that compromise its durability.

Optimizing Your Fabrication Process

To ensure your biomimetic ceramics perform as intended, apply the following principles:

- If your primary focus is Mechanical Strength: Rigorously use vacuum degassing to maximize the density of the ceramic struts and prevent failure under load.

- If your primary focus is Structural Precision: Use degassing to eliminate random defects, ensuring the pore architecture matches your exact biomimetic design.

The integrity of your final ceramic product is determined before the sintering process ever begins.

Summary Table:

| Feature | Impact of Vacuum Degassing | Without Degassing (Risks) |

|---|---|---|

| Pore Structure | Uniform, engineered biomimetic design | Random, unintended voids & defects |

| Skeleton Density | High density ceramic struts | Porous, weakened solid phase |

| Mechanical Strength | Maximum load-bearing capacity | Stress concentrators leading to failure |

| Final Quality | Consistent, high-performance product | Internal flaws & structural instability |

Elevate Your Advanced Ceramic Fabrication with KINTEK

Precision in biomimetic ceramics starts with superior vacuum control. KINTEK provides industry-leading Vacuum Systems, Muffle, Tube, and CVD furnaces tailored for high-temperature material science. Backed by expert R&D and manufacturing, our systems are fully customizable to meet the rigorous demands of your lab's unique gel foaming and sintering processes.

Don't let micro-bubbles compromise your research. Contact us today to find the perfect vacuum degassing and thermal solution for your lab!

Visual Guide

References

- Min Yu, Dou Zhang. Review of Bioinspired Composites for Thermal Energy Storage: Preparation, Microstructures and Properties. DOI: 10.3390/jcs9010041

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Dental Porcelain Sintering Furnace for Dental Laboratories

- Stainless Steel Quick Release Vacuum Chain Three Section Clamp

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What characterization and testing facilities support vacuum brazing? Ensure Joint Integrity for Critical Applications

- What is vacuum sintering and where is it commonly used? Discover High-Purity Material Processing

- How does a vacuum furnace create its working environment? Uncover the Secrets to Purity and Precision

- What function does a vacuum chamber serve in the inkjet printing process for perovskite thin films? Expert Insights

- What are the control features of the vacuum furnace system? Achieve Precise Thermal Processing for Your Lab

- In which industries is vacuum brazing commonly used? Essential for Aerospace, Medical, Automotive, and Electronics

- What industries commonly use vacuum sintering furnaces? Unlock Purity and Strength for High-Tech Applications

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures