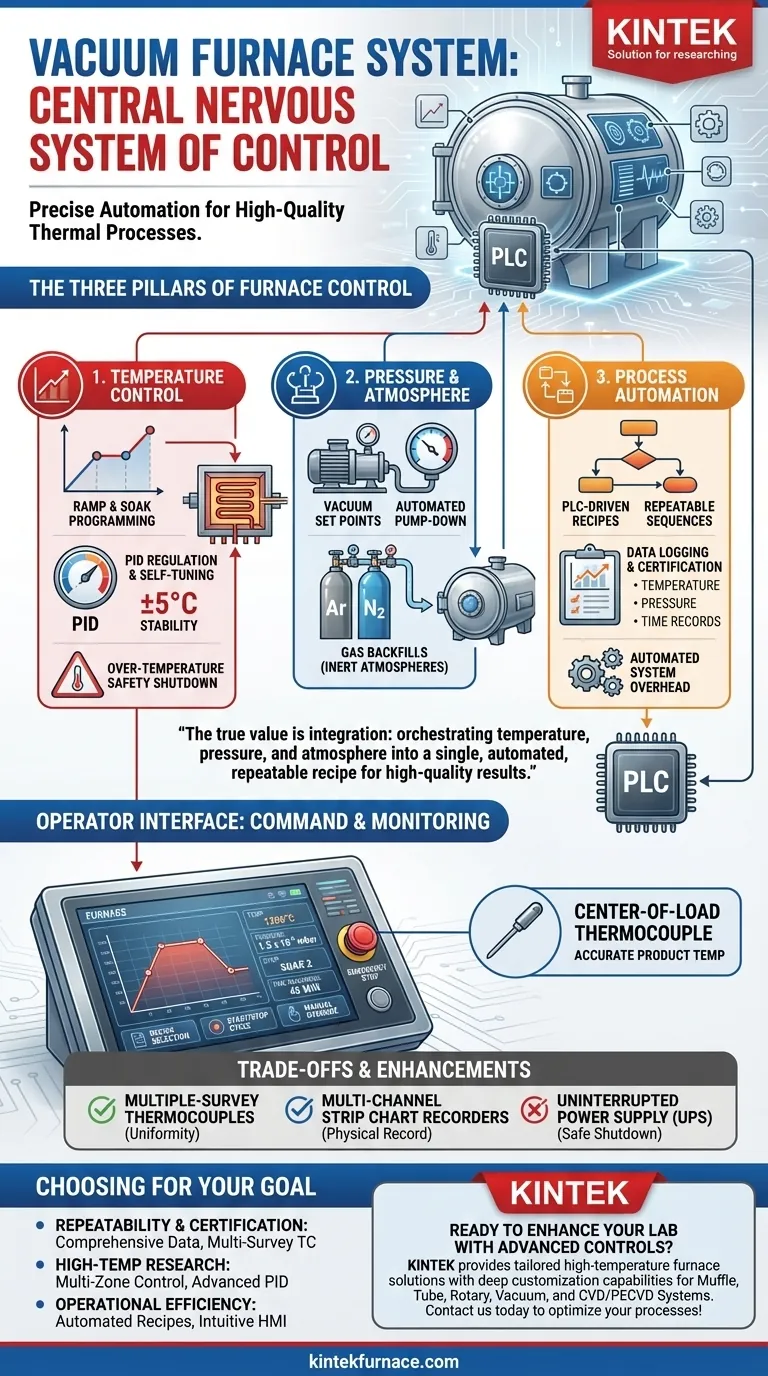

At its core, a vacuum furnace's control system is its central nervous system. It is a combination of hardware and software that automates and precisely manages every stage of a thermal process. Key features include a PLC-driven touch panel for programming temperature ramps and soaks, setting vacuum levels, controlling gas backfills, and automating entire process cycles from pump-down to venting, all while logging data for verification and ensuring operational safety.

The true value of a vacuum furnace's controls is not in any single feature, but in their integration. The system's ability to orchestrate temperature, pressure, and atmosphere into a single, automated, and repeatable recipe is what guarantees high-quality, consistent results.

The Three Pillars of Furnace Control

A modern vacuum furnace control system is built on three fundamental pillars: temperature, pressure, and process sequence automation. Mastering these ensures the integrity of the material being processed.

Temperature Control: Precision and Uniformity

The most critical parameter is almost always temperature. The control system provides high-precision management through several features.

Programmable ramps and soaks allow an operator to define not just the target temperature, but how quickly the furnace heats up (ramp) and how long it holds that temperature (soak).

Advanced regulation systems like PID (Proportional-Integral-Derivative) control, fuzzy logic, and self-tuning algorithms continuously adjust power to the heating elements. This achieves exceptional stability, often within ±5°C of the setpoint.

Safety is managed by an over-temperature controller, an independent system that shuts down the furnace if it exceeds a predefined safety limit, protecting both the equipment and the product.

Pressure & Atmosphere Control: From Vacuum to Backfill

The control system fully manages the furnace's internal environment, from removing air to introducing specific gases.

Operators define vacuum set points, and the PLC automates the complex sequence of operating the roughing and high-vacuum pumps to reach the target pressure efficiently.

The system also controls gas backfills. After the vacuum cycle, it can introduce inert gases like argon or nitrogen to assist in rapid cooling or to create a specific, non-reactive atmosphere for the process.

Process Automation: Ensuring Repeatability

The PLC (Programmable Logic Controller) is the industrial computer that acts as the brain of the operation. It executes the pre-programmed "recipes" flawlessly every time.

This automation covers system overhead functions, such as the entire pump-down and venting sequences, which eliminates the potential for manual error.

Crucially, the system provides data logging, recording all critical process parameters like temperature, pressure, and time. This digital record is essential for quality assurance, process certification, and troubleshooting.

The Operator's Interface: Command and Monitoring

While the PLC does the heavy lifting, the operator interacts with the system through a Human-Machine Interface (HMI), which is typically a color touch panel.

The HMI: Your Window into the Process

The HMI provides a clear, graphical view of the furnace's status. Operators use this interface to select or create recipes, start and stop cycles, and manually override functions when necessary.

It displays real-time data from all sensors, including a digital vacuum display and temperature readings from various thermocouples.

Real-Time Monitoring and Safety

A center-of-load thermocouple is standard, measuring the temperature of the actual product, not just the furnace chamber, for more accurate control.

All critical functions are monitored, and the system includes a prominent emergency stop function that will safely halt all operations immediately in an urgent situation.

Understanding the Trade-offs and Optional Enhancements

The standard control package is highly capable, but specific applications may demand more specialized features.

Standard vs. Advanced Temperature Verification

A single thermocouple is good for basic control, but for large loads or processes requiring strict temperature uniformity (like aerospace components), multiple-survey thermocouples are a vital option. They allow you to map the temperature across the entire hot zone to ensure every part of your load receives the exact same thermal treatment.

System Resilience and Data Integrity

While digital data logging is standard, some regulatory environments still value multi-channel strip chart recorders that provide a physical, tamper-proof record of the process.

An Uninterrupted Power Supply (UPS) is another critical option. It is not designed to run a full heating cycle but to provide enough power during an outage for the control system to perform a safe, controlled shutdown, preventing damage to the furnace or loss of the product.

Making the Right Choice for Your Goal

The ideal control configuration depends entirely on your specific process requirements.

- If your primary focus is process repeatability and certification (e.g., aerospace, medical): You need comprehensive data logging, multiple-survey thermocouples for uniformity validation, and a highly reliable PLC.

- If your primary focus is high-temperature materials research: Multi-zone temperature control and advanced PID regulation with self-tuning are critical for exploring precise material properties.

- If your primary focus is operational efficiency and high throughput: Automated recipes, a clear and intuitive HMI, and automated overhead functions are essential to minimize cycle time and reduce operator error.

Ultimately, understanding these control features empowers you to select and operate a furnace that guarantees the integrity and quality of your final product.

Summary Table:

| Control Feature | Key Functions | Benefits |

|---|---|---|

| Temperature Control | Programmable ramps/soaks, PID regulation, over-temperature safety | Ensures precision, uniformity, and safety in heating processes |

| Pressure & Atmosphere Control | Vacuum set points, gas backfills (e.g., argon, nitrogen) | Manages internal environment for specific process needs |

| Process Automation | PLC-driven recipes, data logging, automated sequences | Guarantees repeatability, reduces errors, and supports quality assurance |

| Operator Interface | HMI touch panel, real-time monitoring, emergency stop | Allows easy control and oversight for efficient operation |

Ready to enhance your lab's thermal processing with advanced vacuum furnace controls? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with tailored high-temperature furnace solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental requirements. Contact us today to discuss how our expertise can optimize your processes and deliver consistent, high-quality results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the heat treatment in a vacuum furnace? Achieve Superior Metallurgical Properties

- How does vacuum heat treatment improve mechanical properties of metals? Enhance Strength and Durability

- Why use a vacuum furnace? Achieve Unparalleled Material Purity and Process Control

- How does a vacuum furnace prevent heat transfer and contamination? Achieve Ultimate Material Purity

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion