At its core, a vacuum furnace creates its unique working environment by systematically removing air from a sealed chamber. Using powerful vacuum pumps, it reduces the internal pressure to a fraction of the normal atmosphere. This low-pressure environment is chemically inert, preventing the material being treated from reacting with gases like oxygen, which is essential for high-purity heat treatment processes.

The fundamental purpose of a vacuum furnace is not just to get hot, but to create a chemically pure space. By drastically lowering the gas pressure, it ensures that the only variable affecting the material is heat, not unwanted reactions with the surrounding atmosphere.

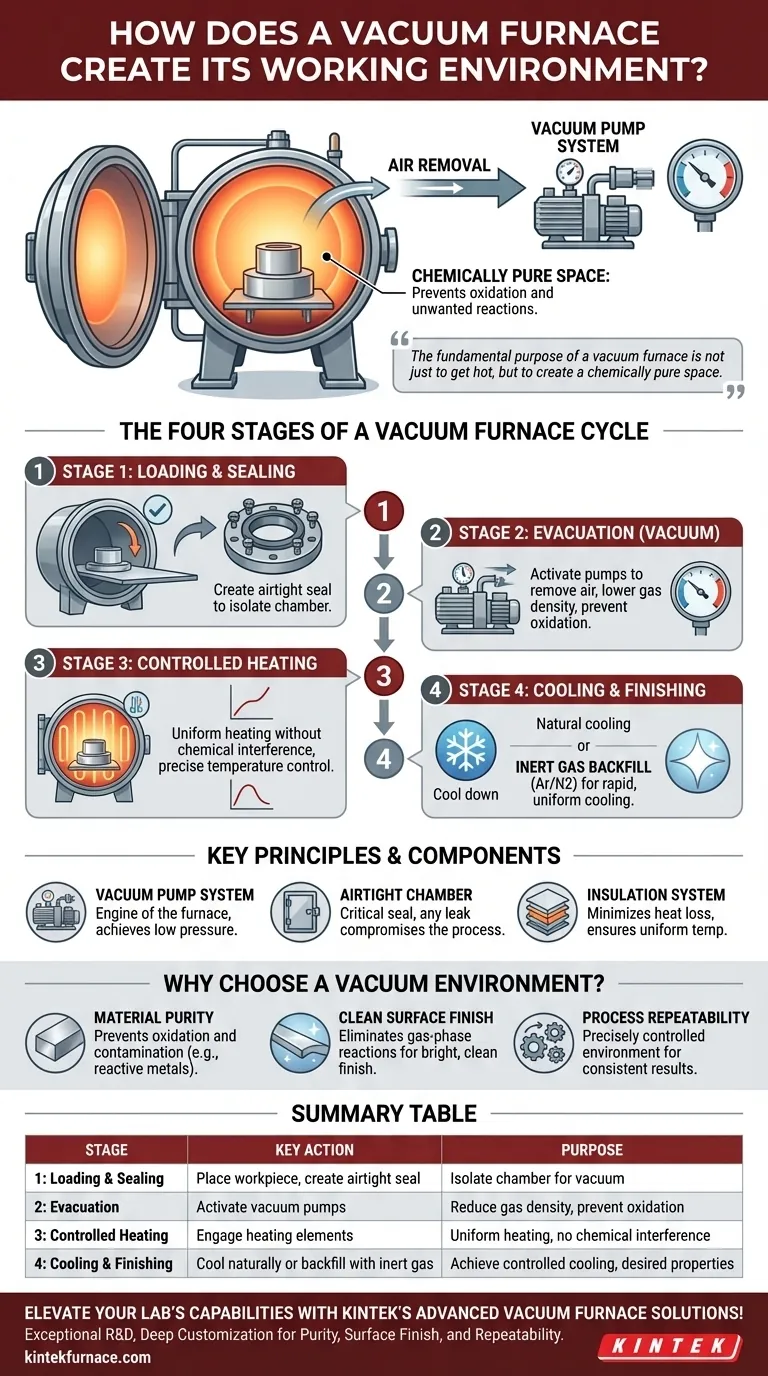

The Four Stages of a Vacuum Furnace Cycle

Understanding how a vacuum furnace works is best done by examining its operational cycle, which can be broken down into four distinct stages. Each stage is critical for achieving the final desired material properties.

Stage 1: Loading and Sealing the Chamber

The process begins by placing the workpiece, or "charge," inside the furnace chamber.

The most critical action in this stage is creating an airtight seal. The chamber, often a quartz or corundum tube with stainless steel flanges, must be completely isolated from the outside atmosphere to allow a vacuum to be established and maintained.

Stage 2: Evacuation (Creating the Vacuum)

This is the defining stage of the process. Once sealed, a system of vacuum pumps is activated to remove air and other gases from the chamber.

The goal is to lower the density of gas molecules to a point where they have minimal contact with the material's surface. This prevents oxidation and other surface reactions that would otherwise occur at high temperatures in the presence of air.

Stage 3: Controlled Heating

With the vacuum established and stable, the furnace's heating elements are engaged.

Advanced control systems precisely manage the temperature, ramping it up to the specified level and holding it there for the required duration. The vacuum ensures that the heat is transferred uniformly without chemical interference.

Stage 4: Cooling and Finishing

After the heating cycle is complete, the charge must be cooled in a controlled manner.

This can involve simply turning off the heaters and letting the furnace cool naturally under vacuum. Alternatively, for faster cooling (quenching), an inert gas like argon or nitrogen is often backfilled into the chamber to rapidly and uniformly draw heat from the part.

Key Principles and Components

The effectiveness of a vacuum furnace relies on the interplay between a few core components and principles. Understanding these helps clarify why this technology is so crucial for advanced materials processing.

The Vacuum Pump System

The pumps are the engine of the furnace. A typical system uses a combination of pumps to first remove the bulk of the air (roughing pumps) and then achieve the final low-pressure state (high-vacuum pumps). The integrity of this system dictates the purity of the working environment.

The Airtight Chamber

The importance of a perfectly sealed chamber cannot be overstated. Any leak, no matter how small, compromises the vacuum by allowing oxygen and other atmospheric gases to re-enter, defeating the purpose of the furnace.

The Insulation System

Modern vacuum furnaces use advanced, multi-layered insulation materials. This serves two functions: it minimizes heat loss to ensure stable and uniform temperatures, and it reduces overall energy consumption, lowering operational costs.

Why Choose a Vacuum Environment?

The decision to use a vacuum furnace is driven by the specific requirements of the material and the desired outcome. The unique environment it creates is the solution to several common manufacturing challenges.

- If your primary focus is material purity: The vacuum prevents oxidation and contamination, which is critical for reactive metals like titanium or for medical-grade implants.

- If your primary focus is a clean surface finish: By eliminating gas-phase reactions, a vacuum furnace delivers a bright, clean finish directly from the furnace, often removing the need for secondary cleaning operations.

- If your primary focus is process repeatability: The precisely controlled vacuum level and temperature ensure that every cycle is virtually identical, leading to highly consistent and predictable results batch after batch.

Ultimately, the vacuum environment transforms the furnace from a simple oven into a precision instrument for material transformation.

Summary Table:

| Stage | Key Action | Purpose |

|---|---|---|

| 1: Loading and Sealing | Place workpiece and create airtight seal | Isolate chamber from atmosphere to enable vacuum |

| 2: Evacuation | Activate vacuum pumps to remove air | Reduce gas density to prevent oxidation and contamination |

| 3: Controlled Heating | Engage heating elements under vacuum | Uniformly heat material without chemical interference |

| 4: Cooling and Finishing | Cool naturally or with inert gas backfill | Achieve controlled cooling for desired material properties |

Elevate your lab's capabilities with KINTEK's advanced vacuum furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs for purity, surface finish, and repeatability. Contact us today to discuss how we can optimize your heat treatment processes!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Induction Melting Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today