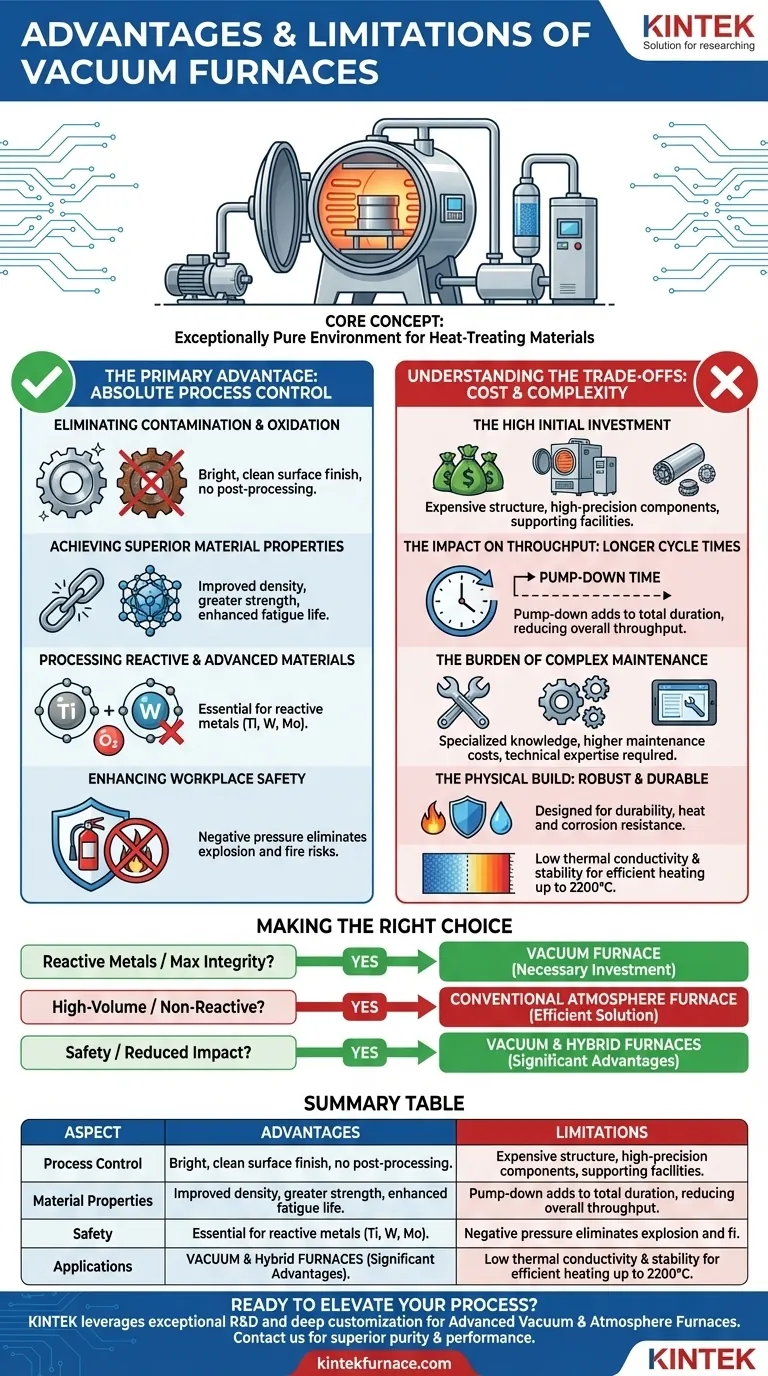

At their core, vacuum furnaces provide an exceptionally pure environment for heat-treating materials. Their primary advantage is the ability to produce parts with superior properties and clean surfaces by preventing oxidation and contamination. However, this high level of control comes with significant trade-offs, including high equipment costs, longer processing cycles, and complex maintenance requirements.

Choosing a heat treatment method is a critical engineering decision that balances process purity against operational cost. A vacuum furnace is not a universal upgrade; it is a specialized tool justified only when the material's properties or reactivity demand an environment completely free from atmospheric contamination.

The Primary Advantage: Absolute Process Control

The defining benefit of a vacuum furnace is its ability to create a chemically non-reactive environment. By removing air and other gases, it eliminates variables that can compromise the quality of the final product.

Eliminating Contamination and Oxidation

Removing oxygen and other atmospheric gases prevents reactions on the metal's surface during heating. This results in a bright, clean surface finish, eliminating the need for post-processing steps like cleaning or pickling.

Achieving Superior Material Properties

The pristine vacuum environment ensures that the material's integrity is maintained. This leads to parts with improved and more consistent properties, such as higher density, greater strength, and enhanced fatigue life.

Processing Reactive and Advanced Materials

For reactive metals like titanium, tungsten, and molybdenum, a vacuum is not just beneficial—it is essential. These materials would be irreversibly damaged by reacting with oxygen at high temperatures, making vacuum furnaces the only viable option for their heat treatment.

Enhancing Workplace Safety

Vacuum furnaces operate at negative pressure, which inherently eliminates the risk of explosion present in pressurized vessels. The extremely low oxygen content also removes the potential for fire, making them significantly safer than many conventional heating furnaces.

Understanding the Trade-offs: Cost and Complexity

The precision and purity of a vacuum furnace come at a price. Decision-makers must weigh these significant operational and financial commitments against the required process outcomes.

The High Initial Investment

Vacuum furnaces are expensive. Their cost is driven by complex structures, the need for high-precision components like vacuum pumps and gauges, and stringent manufacturing requirements for seals. Furthermore, they require supporting facilities, such as dedicated cooling water and gas purification systems, which add to the total capital investment.

The Impact on Throughput: Longer Cycle Times

Before the heating cycle can begin, the furnace must be pumped down to the required vacuum level. This pump-down time adds to the total process duration, potentially reducing overall throughput compared to conventional atmosphere furnaces.

The Burden of Complex Maintenance

Maintaining the integrity of a high-vacuum system is a specialized task. It requires deep knowledge of vacuum pumps, seals, and diagnostic equipment. This complexity increases maintenance costs and demands a higher level of technical expertise from staff.

The Physical Build: What Makes Them Robust

Beyond their processing capabilities, vacuum furnaces are typically engineered for a long operational life under demanding conditions.

Designed for Durability

These furnaces are constructed with materials that offer excellent heat and corrosion resistance. Their robust design makes them resistant to the stresses of repeated thermal cycling, contributing to a long service life.

Low Thermal Conductivity and Stability

The materials used in their construction, particularly for insulation, have low thermal conductivity and excellent thermal stability. This ensures energy is focused on the workpiece for efficient heating and that the furnace itself remains chemically stable even at maximum temperatures, which can reach up to 2200°C in high-vacuum models.

Making the Right Choice for Your Application

Your decision must be driven by the specific demands of your material and the non-negotiable requirements of the final product.

- If your primary focus is processing reactive metals or achieving maximum material integrity: A vacuum furnace is often the only viable choice, and the high cost is a necessary investment in quality.

- If your primary focus is high-volume production of non-reactive metals: The longer cycle times and high cost of a vacuum furnace may be prohibitive, making a conventional atmosphere furnace a more efficient solution.

- If your primary focus is safety and reduced environmental impact: Vacuum and hybrid furnaces offer significant advantages over traditional pressure or direct-fire systems, justifying their consideration even for less demanding applications.

Ultimately, a vacuum furnace is an investment in precision, justified when the quality and properties of the end product cannot be compromised.

Summary Table:

| Aspect | Advantages | Limitations |

|---|---|---|

| Process Control | Prevents oxidation and contamination; clean surfaces | High initial investment and complex maintenance |

| Material Properties | Improves strength, density, and fatigue life | Longer processing cycles reduce throughput |

| Safety | Eliminates explosion and fire risks | Requires specialized technical expertise |

| Applications | Essential for reactive metals like titanium and tungsten | Less suitable for high-volume, non-reactive metals |

Ready to elevate your heat treatment process with tailored vacuum furnace solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnaces, including Vacuum & Atmosphere Furnaces, Muffle, Tube, Rotary Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental needs, delivering superior purity, safety, and performance for reactive materials. Contact us today to discuss how we can optimize your laboratory's efficiency and achieve unmatched material integrity!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance