In short, vacuum furnaces create an exceptionally clean and controlled environment, which is critical for producing high-performance optical materials. This process prevents contamination from atmospheric gases, improves the structural integrity of the material, and ultimately enhances its optical properties like clarity and light transmittance.

The core benefit of a vacuum furnace is not just removing air, but eliminating the unpredictable chemical reactions and physical impurities that air introduces. This control allows for the production of materials with unparalleled purity and structural perfection, which is the foundation of high-quality optics.

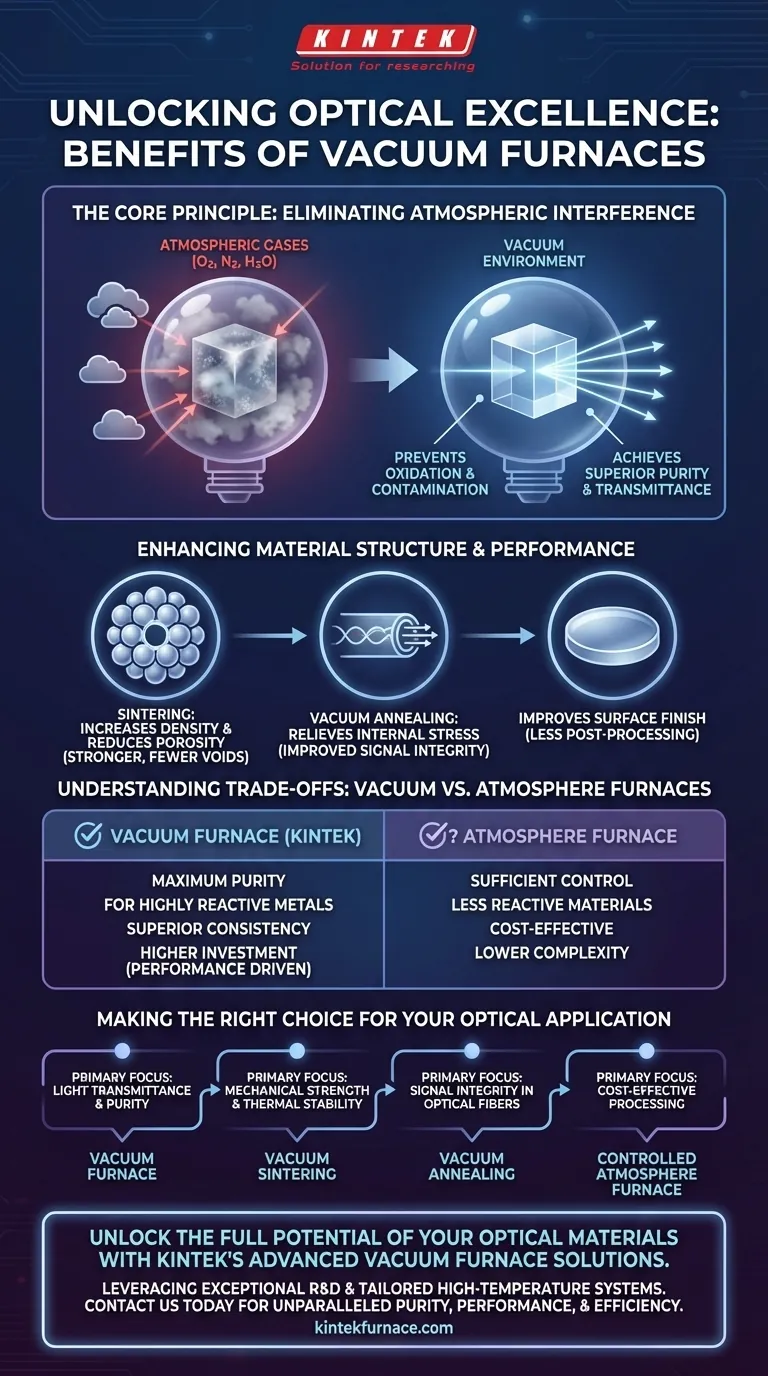

The Core Principle: Eliminating Atmospheric Interference

The primary function of a vacuum furnace is to remove atmospheric gases—oxygen, nitrogen, water vapor—from the processing chamber. This seemingly simple act has profound implications for the material being treated.

Preventing Oxidation and Contamination

Many materials used in optics, especially at high processing temperatures, will react with oxygen. This oxidation can create a cloudy surface layer or internal impurities that degrade optical performance.

By removing oxygen, a vacuum furnace ensures the material remains chemically pure. This prevents the formation of oxides that would otherwise scatter or absorb light, compromising the clarity of a lens or the efficiency of a fiber.

Achieving Superior Purity and Transmittance

Without atmospheric gases to interfere, the material can be processed in its purest form. For optical components like lenses, this directly translates to higher light transmittance and uniformity.

A cleaner material simply allows more light to pass through without distortion or loss of intensity, a critical requirement for any high-performance optical system.

Enhancing Material Structure and Performance

Beyond chemical purity, a vacuum environment fundamentally alters and improves the physical structure of the material.

Increasing Density and Reducing Porosity

Processes like sintering, used to create advanced ceramics for mirrors and lenses, benefit immensely from a vacuum. The vacuum helps pull residual gases out from between the material's particles, allowing them to bond more tightly.

This results in a final product with near-theoretical density and minimal porosity. Fewer internal voids mean greater mechanical strength, thermal resistance, and, most importantly for optics, fewer sites for light to scatter internally.

Relieving Internal Stress

Optical fibers and precision-molded glass can harbor internal stresses from their manufacturing process. These stresses can cause optical distortions and make the components fragile.

Vacuum annealing, which involves heating the material in a vacuum and cooling it slowly, allows these stresses to relax uniformly. This improves the transmission performance of optical fibers and the stability of lenses.

Improving Surface Finish

Because a vacuum prevents reactions at the surface, the material emerges from the furnace with an exceptionally clean and smooth finish, reducing the need for extensive post-processing and polishing.

Understanding the Trade-offs: Vacuum vs. Atmosphere Furnaces

While powerful, a vacuum furnace is not the only tool for thermal processing. Understanding its specific advantages over a conventional atmosphere furnace is key.

When to Use a Vacuum Furnace

A vacuum environment is essential when working with highly reactive metals (like tungsten or molybdenum), when the goal is maximum purity and density, or when even trace amounts of atmospheric gas would compromise the final product's performance.

The Role of Atmosphere Furnaces

Atmosphere furnaces, which use a controlled flow of specific gases (like nitrogen or argon), are also used for annealing glass or sintering some coatings. They provide a degree of control but cannot match the purity of a vacuum. They are often a sufficient and more cost-effective choice when the material is less reactive and the optical requirements are less stringent.

Cost and Complexity

Vacuum systems are inherently more complex and typically have higher initial and operational costs than atmosphere furnaces. The choice depends entirely on whether the superior material properties and consistency justify the investment.

Making the Right Choice for Your Optical Application

The decision to use a vacuum furnace should be driven by the specific performance goals of your final product.

- If your primary focus is maximum light transmittance and purity: A vacuum furnace is the ideal choice to prevent oxidation and ensure the material is chemically pristine.

- If your primary focus is mechanical strength and thermal stability: Vacuum sintering is necessary to achieve the high density and low porosity required for durable optical ceramics.

- If your primary focus is signal integrity in optical fibers: Vacuum annealing is the most effective method for relieving internal stresses that degrade transmission performance.

- If your primary focus is cost-effective processing of less sensitive glass: A controlled atmosphere furnace may provide sufficient process control for your application.

By controlling the processing environment at a molecular level, vacuum furnaces empower you to define the exact properties of your final optical material.

Summary Table:

| Benefit | Description |

|---|---|

| Prevents Oxidation | Eliminates atmospheric gases to avoid chemical reactions and impurities. |

| Enhances Purity | Ensures material remains chemically pure for higher light transmittance. |

| Improves Density | Reduces porosity through processes like sintering for stronger materials. |

| Relieves Stress | Uses vacuum annealing to reduce internal stresses in optical components. |

| Improves Surface Finish | Results in clean, smooth surfaces with less post-processing needed. |

Unlock the full potential of your optical materials with KINTEK's advanced vacuum furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored high-temperature furnace systems, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our deep customization capabilities ensure precise alignment with your unique experimental needs, delivering unparalleled purity, performance, and efficiency. Contact us today to discuss how we can enhance your production process and achieve superior results!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What role does a vacuum induction melting furnace play in Fe-5%Mn-C alloys? Ensure Chemical Integrity and High Purity

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- What is the purpose of vacuum melting, casting and re-melting equipment? Achieve High-Purity Metals for Critical Applications

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- How does the Vacuum Induction Melting (VIM) process work? Achieve Superior Metal Purity and Control