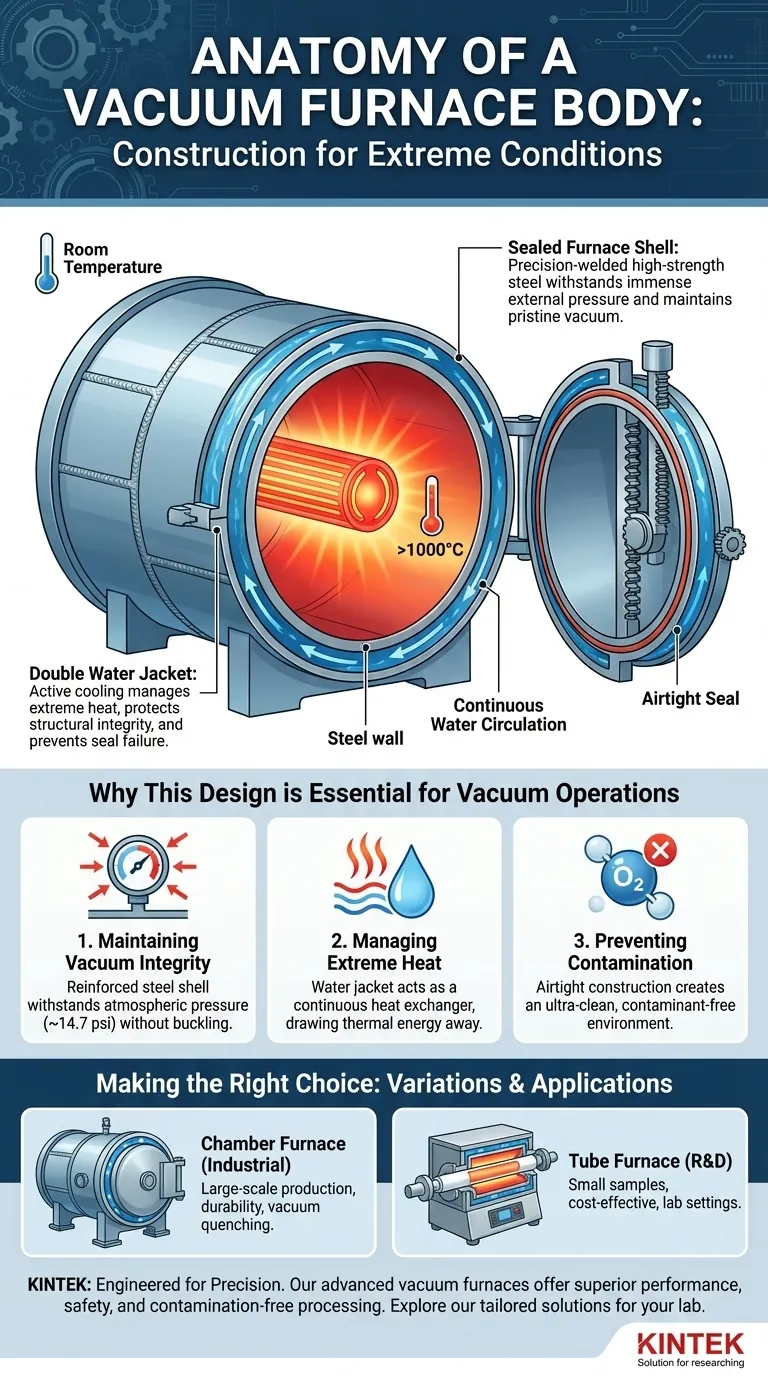

A vacuum furnace body is fundamentally a reinforced, sealed vessel designed for extreme conditions. It is typically constructed by welding and pressing high-strength steel plates to form a cylindrical or rectangular chamber. The most critical feature of this construction is a double-wall, or "water jacket," design that enables precise temperature management and ensures structural integrity under vacuum.

The core principle behind a vacuum furnace's construction is not just containment, but control. Its double-walled, water-cooled steel body is specifically engineered to simultaneously manage immense external atmospheric pressure, contain extreme internal heat, and maintain a pristine, contamination-free vacuum.

The Core Components of Construction

A vacuum furnace body, often called the furnace chamber or shell, is more than a simple steel box. It is an integrated system where each component serves a critical function.

The Sealed Furnace Shell

The main structure is the sealed furnace shell. This is fabricated from high-strength steel plates chosen for their ability to withstand significant pressure differentials and temperature fluctuations without deforming.

The plates are precisely cut, formed, and then welded together to create an airtight vessel. The quality of these welds is paramount to the furnace's ability to achieve and hold a deep vacuum.

The Double Water Jacket

The defining feature of most vacuum furnace bodies is the double water jacket. This means the furnace has an inner and an outer wall.

The space between these two steel walls is a channel for continuously circulating cooling water. This active cooling is essential for keeping the outer shell at or near room temperature, even when the interior is over 1000°C.

This design protects the structural integrity of the steel, prevents the seals from failing due to heat, and ensures the safety of operators and surrounding equipment.

The Furnace Door

The furnace door is constructed with the same double water jacket design as the body. It is a heavy, robust component that must create a perfect seal when closed.

It often uses a gear and rack mechanism or a hydraulic system to ensure it can be opened and closed smoothly despite its weight. The seal itself is typically achieved with specialized high-temperature O-rings or flanges that are compressed when the door is locked.

Why This Design is Essential for Vacuum Operations

The specific construction of the furnace body is a direct solution to the challenges posed by high-temperature vacuum processing.

Maintaining Vacuum Integrity

When the air is removed from the chamber, the exterior of the furnace is subjected to the full force of atmospheric pressure (approximately 14.7 psi at sea level). The reinforced steel shell is engineered to withstand this constant external pressure without buckling.

Managing Extreme Heat

Heating elements inside the furnace, often made of graphite or molybdenum, generate intense radiant heat. The water jacket acts as a continuous heat exchanger, drawing this thermal energy away from the outer body and preventing it from overheating.

Preventing Contamination

The core purpose of a vacuum furnace is to process materials without them reacting with oxygen or other gases in the air. The airtight, welded construction is what makes it possible to remove virtually all the air and create the ultra-clean environment necessary for processes like annealing, brazing, and vacuum carburizing.

Understanding the Trade-offs and Variations

While the water-jacketed steel chamber is common, it's important to understand its context and the alternatives that exist.

Chamber vs. Tube Furnaces

The design described above is for a "chamber furnace." A different type, the vacuum tube furnace, is often used for smaller experiments.

In this design, a ceramic (quartz or corundum) tube acts as the primary vacuum vessel. The "furnace body" is then the heating and insulation structure built around this tube. This is less robust for industrial use but allows for easier sample handling in a lab setting.

Construction Complexity and Cost

The double-wall, water-cooled design is significantly more complex and expensive to manufacture than a simple chamber. It requires precision welding, leak testing, and an entire subsystem for pumping and circulating water.

Reliance on the Vacuum System

The furnace body is only one part of the equation. Its design must integrate seamlessly with the vacuum system, which includes a series of pumps and gauges needed to evacuate the chamber. The body must include robust, leak-proof ports for connecting these critical components.

Making the Right Choice for Your Goal

The construction of a vacuum furnace is directly tied to its intended application. Understanding the design helps you evaluate its suitability for your specific needs.

- If your primary focus is large-scale industrial production: A double-jacketed steel chamber furnace is the industry standard for its durability, capacity, and ability to handle demanding processes like vacuum quenching.

- If your primary focus is research and development: A vacuum tube furnace may offer a more cost-effective and flexible solution for testing small material samples.

- If your primary focus is safety and performance: The integrity of the shell's welds and the efficiency of the water-cooling system are the most critical construction features to scrutinize.

Ultimately, the furnace body is an engineered environment, and its construction directly enables the precise control over temperature and atmosphere required for advanced material processing.

Summary Table:

| Component | Key Features | Purpose |

|---|---|---|

| Sealed Furnace Shell | High-strength steel plates, precision welding | Withstands pressure differentials and maintains vacuum integrity |

| Double Water Jacket | Inner and outer walls with circulating water | Manages heat, prevents overheating, and ensures structural safety |

| Furnace Door | Double water jacket, gear/hydraulic mechanism, high-temperature seals | Provides airtight closure and easy access |

Unlock Precision in Your Lab with KINTEK's Advanced Vacuum Furnaces

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need robust industrial chambers or flexible R&D setups, we ensure superior performance, safety, and contamination-free processing. Contact us today to discuss how our tailored solutions can enhance your material processing and achieve your goals!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- How does vacuum heat treatment reduce workpiece deformation? Achieve Superior Dimensional Stability

- What is the mechanism of a vacuum sintering furnace for AlCoCrFeNi2.1 + Y2O3? Optimize Your High-Entropy Alloy Processing

- Why are vacuum furnaces considered important in various industries? Unlock Superior Material Performance

- Why might a vacuum furnace maintain vacuum during cooling? Protect Workpieces from Oxidation and Control Metallurgy

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing