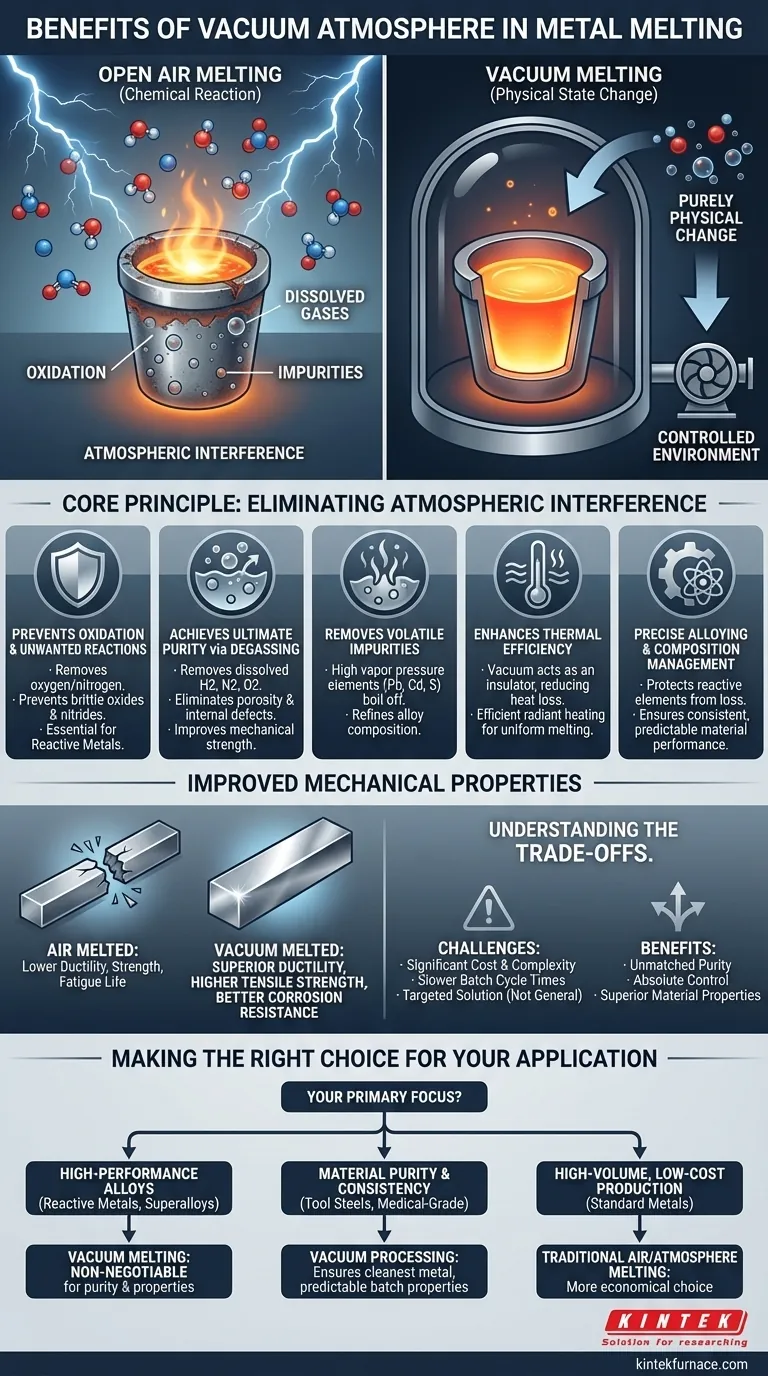

In short, using a vacuum for metal melting fundamentally transforms the process from a chemical reaction with the atmosphere to a purely physical state change. This controlled environment prevents oxidation, removes dissolved gases and volatile impurities, and ensures the highest possible purity and performance of the final material.

Moving the melting process into a vacuum is not a minor optimization; it is a strategic decision to achieve absolute control. It allows for the production of materials with a level of purity and specific properties that are simply unattainable when melted in the presence of air.

The Core Principle: Eliminating Atmospheric Interference

Melting metal in the open air is an act of compromise. The atmosphere, rich in oxygen and nitrogen, actively reacts with the molten metal, altering its chemistry and degrading its properties. A vacuum furnace removes this variable entirely.

Preventing Oxidation and Unwanted Reactions

The most immediate benefit of a vacuum is the removal of oxygen. At high temperatures, molten metals readily react with oxygen to form oxides, which introduce brittle, non-metallic inclusions into the final product.

Similarly, nitrogen can react with certain metals to form hard nitrides. By evacuating the chamber, you prevent these undesirable chemical reactions, preserving the metal's intrinsic properties. This is non-negotiable for reactive metals like titanium, zirconium, and niobium.

Achieving Ultimate Purity via Degassing

Molten metals can hold a significant amount of dissolved gases like hydrogen, nitrogen, and oxygen. As the metal cools and solidifies, these gases are forced out of solution, creating microscopic voids and porosity.

The low-pressure environment of a vacuum furnace effectively pulls these dissolved gases out of the molten bath. This degassing process is critical for eliminating internal defects, which dramatically improves the metal's mechanical strength and fatigue life.

Removing Volatile Impurities

A vacuum also facilitates the removal of other unwanted elements. Impurities with a high vapor pressure (like lead, cadmium, sulfur, or magnesium) will essentially boil off from the molten metal under vacuum and be removed by the pump system, further refining the alloy.

Gaining Unprecedented Process Control

Beyond purity, a vacuum atmosphere provides a level of operational control that is impossible in air. This control translates directly to thermal efficiency and compositional accuracy.

Enhancing Thermal Efficiency

In a standard furnace, a significant amount of heat is lost to the surrounding air through convection. A vacuum is an excellent insulator, so this mode of heat loss is virtually eliminated.

Heat is transferred primarily through radiation, leading to a more efficient, uniform, and often faster melting process. This is particularly beneficial in vacuum induction melting (VIM), where magnetic fields can pass through the vacuum to heat the metal directly.

Precise Alloying and Composition Management

When creating specific alloys, maintaining the exact ratio of elements is paramount. In air, some expensive or reactive alloying elements can be lost to oxidation.

In a vacuum, these elements are protected. This ensures the final chemical composition of the alloy is precisely what was designed, leading to consistent and predictable material performance batch after batch.

Improved Mechanical Properties

The cumulative effect of these benefits—higher purity, no inclusions, and zero porosity—is a dramatic improvement in the metal's final characteristics.

Vacuum-melted metals consistently exhibit superior ductility, higher tensile strength, and better corrosion resistance. This is why they are specified for the most demanding applications in aerospace, defense, medical implants, and power generation.

Understanding the Trade-offs

While the benefits are clear, vacuum melting is not a universal solution. It involves significant technical and economic considerations.

Significant Cost and Complexity

Vacuum furnaces are complex systems that are expensive to purchase, operate, and maintain. The costs associated with high-capacity vacuum pumps, robust chamber construction, and sophisticated controls are substantial.

Slower Batch Cycle Times

The need to pump down the furnace chamber to the required vacuum level adds significant time to each melting cycle. This makes the process inherently slower than continuous or batch melting in air.

A Targeted Solution, Not a General One

For many common metals and applications, such as basic structural steel or standard aluminum castings, the level of purity achieved through vacuum melting is unnecessary. The added cost and complexity are not justified when the application does not demand ultimate performance.

Making the Right Choice for Your Application

The decision to use vacuum melting should be driven entirely by the required properties of the final material.

- If your primary focus is high-performance alloys: Vacuum melting is non-negotiable for achieving the required purity and mechanical properties for reactive metals (e.g., titanium) or superalloys (e.g., Inconel).

- If your primary focus is material purity and consistency: For tool steels, magnetic alloys, and medical-grade materials, vacuum processing ensures the cleanest possible metal with predictable batch-to-batch properties.

- If your primary focus is high-volume and low-cost production: For non-reactive metals where standard purity is acceptable, traditional air or controlled atmosphere melting remains the more economical choice.

Ultimately, choosing vacuum melting is an investment in absolute control over your material's final chemistry and structural integrity.

Summary Table:

| Benefit | Description |

|---|---|

| Prevents Oxidation | Eliminates oxygen and nitrogen reactions, preserving metal integrity. |

| Removes Dissolved Gases | Degassing reduces porosity, improving strength and fatigue life. |

| Eliminates Volatile Impurities | Vaporizes unwanted elements like lead and sulfur for higher purity. |

| Enhances Thermal Efficiency | Vacuum insulation allows uniform, faster melting via radiation. |

| Improves Mechanical Properties | Results in superior ductility, tensile strength, and corrosion resistance. |

Ready to elevate your metal melting with unmatched purity and control? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for your needs. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is backed by strong deep customization capabilities to precisely meet unique experimental requirements. Whether you're working with reactive metals, superalloys, or medical-grade materials, we can help you achieve superior results. Contact us today to discuss how our solutions can benefit your laboratory!

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How does graphite's chemical resistance benefit vacuum furnace processes? Achieve High-Purity, Contamination-Free Results

- How does a vacuum environment improve melting efficiency? Boost Purity and Speed in Metal Processing

- How do vacuum furnaces ensure precise heat treatment results? Master Control for Superior Material Properties

- What is the specific purpose of using a vacuum high-temperature furnace for powder pre-treatment? Ensure Sharp Interfaces

- What advantages does the non-linear processing in a vacuum furnace offer? Achieve Precise Material Control

- What are the advantages of using a Vacuum Evaporation-Assisted (VEA) reactor? Cut Costs and Boost Synthesis Efficiency

- What creates the low-oxygen environment in a vacuum furnace? Discover the Key to Oxidation-Free Heat Treatment

- What is the primary function of a vacuum sintering furnace in the production of cemented carbide? Achieve Peak Density