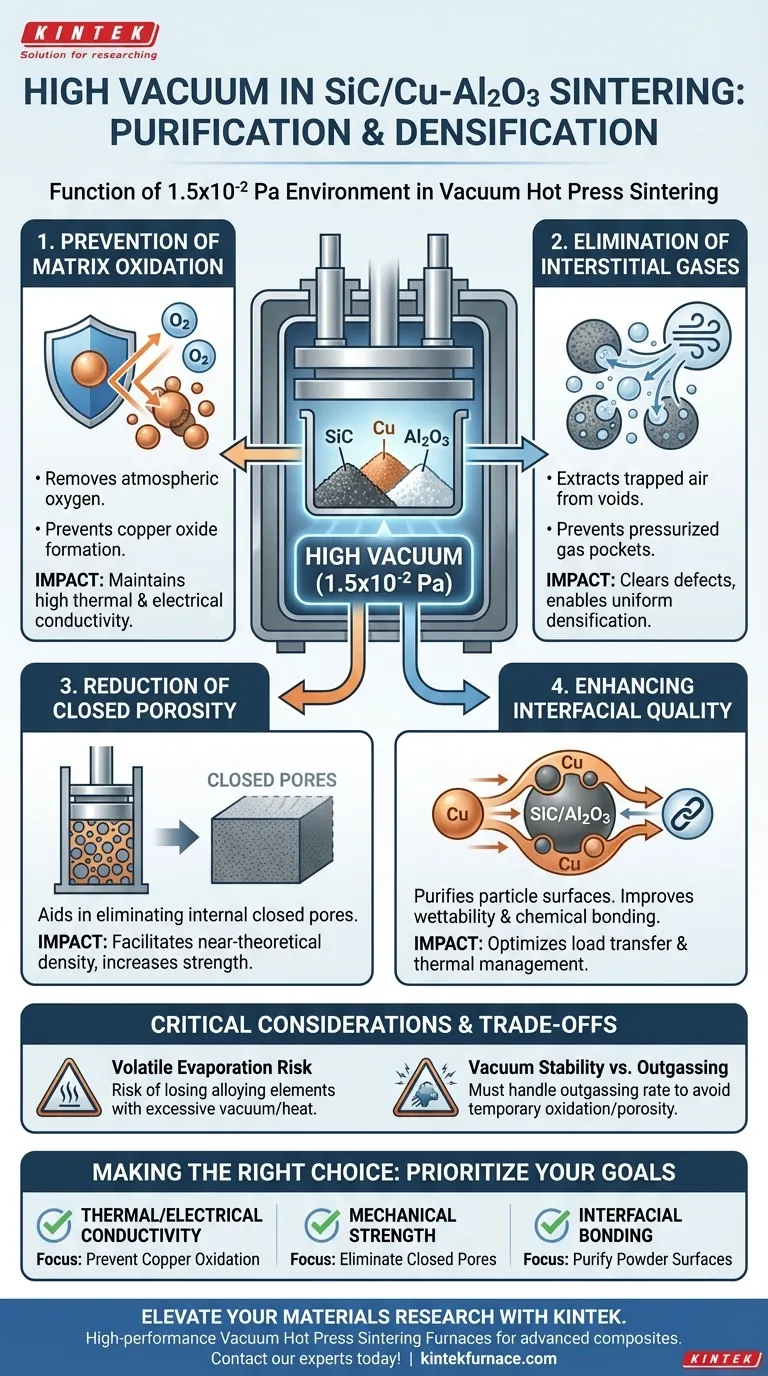

The specific function of the high vacuum environment (1.5x10^-2 Pa) is to act as a critical purification and densification agent. By continuously removing gases from the interstitial spaces between powder particles, this environment prevents the oxidation of the copper matrix at elevated temperatures. It ensures the chemical stability of the SiC, Cu, and Al2O3 materials and eliminates closed pores, directly facilitating the production of high-density composites.

Core Takeaway Achieving high performance in SiC/Cu-Al2O3 composites requires more than just heat and pressure; it demands a pristine chemical environment. The high vacuum serves as an active barrier against oxidation and a mechanism for gas extraction, ensuring that the final material is chemically pure, structurally dense, and free of pore-related defects.

The Mechanisms of Vacuum-Assisted Sintering

To understand why a vacuum level of 1.5x10^-2 Pa is necessary, we must look beyond simple air removal and examine how it dictates the microstructural evolution of the composite.

Prevention of Matrix Oxidation

The primary threat to Copper (Cu) matrix composites during sintering is oxidation. At high sintering temperatures, copper reacts readily with oxygen.

The vacuum environment eliminates atmospheric oxygen, preventing the formation of copper oxides. This is vital because oxide layers act as thermal barriers and structural weak points, degrading the superior thermal and electrical conductivity inherent to copper.

Elimination of Interstitial Gases

Powder metallurgy involves compressing loose particles that have air trapped in the voids (interstitial spaces) between them.

If these gases are not removed, they become trapped inside the material as it densifies. The vacuum system continuously extracts these interstitial gases, ensuring they do not form pressurized pockets that resist densification.

Reduction of Closed Porosity

The ultimate goal of hot pressing is near-theoretical density. As the material sinters, open pores can close off, trapping gas inside.

By maintaining a high vacuum, the system aids in eliminating closed pores. Without internal gas pressure to counteract the external mechanical force, the material can be compressed more effectively, resulting in a denser, stronger final product.

Enhancing Interfacial Quality

The performance of a composite like SiC/Cu-Al2O3 is defined by the quality of the interface between the metal matrix (Cu) and the ceramic reinforcements (SiC/Al2O3).

Ensuring Chemical Stability

The primary reference highlights that the vacuum ensures the chemical stability of the powder materials. By removing reactive elements from the atmosphere, the vacuum prevents unwanted chemical reactions that could degrade the ceramic particles or the copper matrix.

Improving Wettability and Bonding

While the primary focus is gas removal, the vacuum also purifies the surface of the powder particles. Clean, oxide-free surfaces exhibit better wettability.

This allows the copper matrix to flow more easily around the SiC and Al2O3 particles, creating a stronger mechanical and chemical bond. This is essential for effective load transfer and thermal management in the composite.

Critical Trade-offs and Considerations

While a high vacuum is beneficial, it requires precise control to avoid processing errors.

The Risk of Volatile Evaporation

A high vacuum lowers the boiling point of materials. While intended to remove impurities, excessive vacuum combined with extreme heat could potentially lead to the evaporation of volatile alloying elements or binders too aggressively.

Vacuum Stability vs. Outgassing

The vacuum pump must be capable of handling the "outgassing" rate. As the powder heats up, it releases adsorbed moisture and volatiles. If the vacuum system cannot maintain 1.5x10^-2 Pa against this surge of gas, temporary oxidation or porosity can occur, compromising the batch.

Making the Right Choice for Your Project

The vacuum level is a tool to achieve specific material properties. Here is how to prioritize based on your specific engineering goals:

- If your primary focus is Thermal/Electrical Conductivity: Prioritize the vacuum's ability to prevent copper oxidation, as even trace oxides will significantly scatter electrons and phonons.

- If your primary focus is Mechanical Strength: Focus on the vacuum's role in eliminating closed pores, as porosity acts as a stress concentrator that leads to premature mechanical failure.

- If your primary focus is Interfacial Bonding: Rely on the vacuum to purify powder surfaces, ensuring optimal wetting between the ceramic reinforcement and the metal matrix.

The high vacuum environment is not a passive setting; it is an active processing parameter that defines the purity, density, and ultimate performance of your SiC/Cu-Al2O3 composite.

Summary Table:

| Function | Mechanism | Impact on Composite Quality |

|---|---|---|

| Oxidation Prevention | Removes atmospheric oxygen | Maintains high thermal & electrical conductivity |

| Gas Extraction | Clears interstitial voids | Eliminates pressurized gas pockets and defects |

| Densification | Reduces closed porosity | Facilitates near-theoretical material density |

| Surface Purification | Removes surface oxides | Enhances wettability and interfacial bonding |

Elevate Your Materials Research with KINTEK

Precision in sintering requires more than just heat—it demands the perfect atmospheric environment. Backed by expert R&D and manufacturing, KINTEK offers high-performance Vacuum Hot Press Sintering Furnaces, as well as Muffle, Tube, Rotary, and CVD systems. Whether you are developing advanced SiC/Cu-Al2O3 composites or specialized ceramics, our customizable lab high-temp furnaces are engineered to meet your unique density and purity requirements.

Ready to achieve superior material properties? Contact our technical experts today to find the perfect furnace solution for your lab!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- Why is controlling sulfur levels beneficial for the removal of tin impurities? Optimize Vacuum Steelmaking Efficiency

- What are the primary process functions of a vacuum oven in Fe3O4/C@PM synthesis? Ensure Material Integrity.

- Why is vacuum brazing particularly suitable for aerospace applications? Achieve Strong, Pure Joints for Critical Components

- What are the core functions of vacuum devices in Polymer Impregnation Method? Enhance Deep Structural Reinforcement

- Why are vacuum chamber furnaces essential for industrial heat treatment? Ensure Contaminant-Free Precision

- What are the components of a microwave sintering furnace? Boost Efficiency with Advanced Heating Systems

- What is the main purpose of a vacuum sintering furnace? Fuse Powders into High-Performance Dense Parts

- What role does a high-vacuum or low-oxygen furnace play in NiCoCrAlY pre-oxidation? Master Selective Oxidation Control