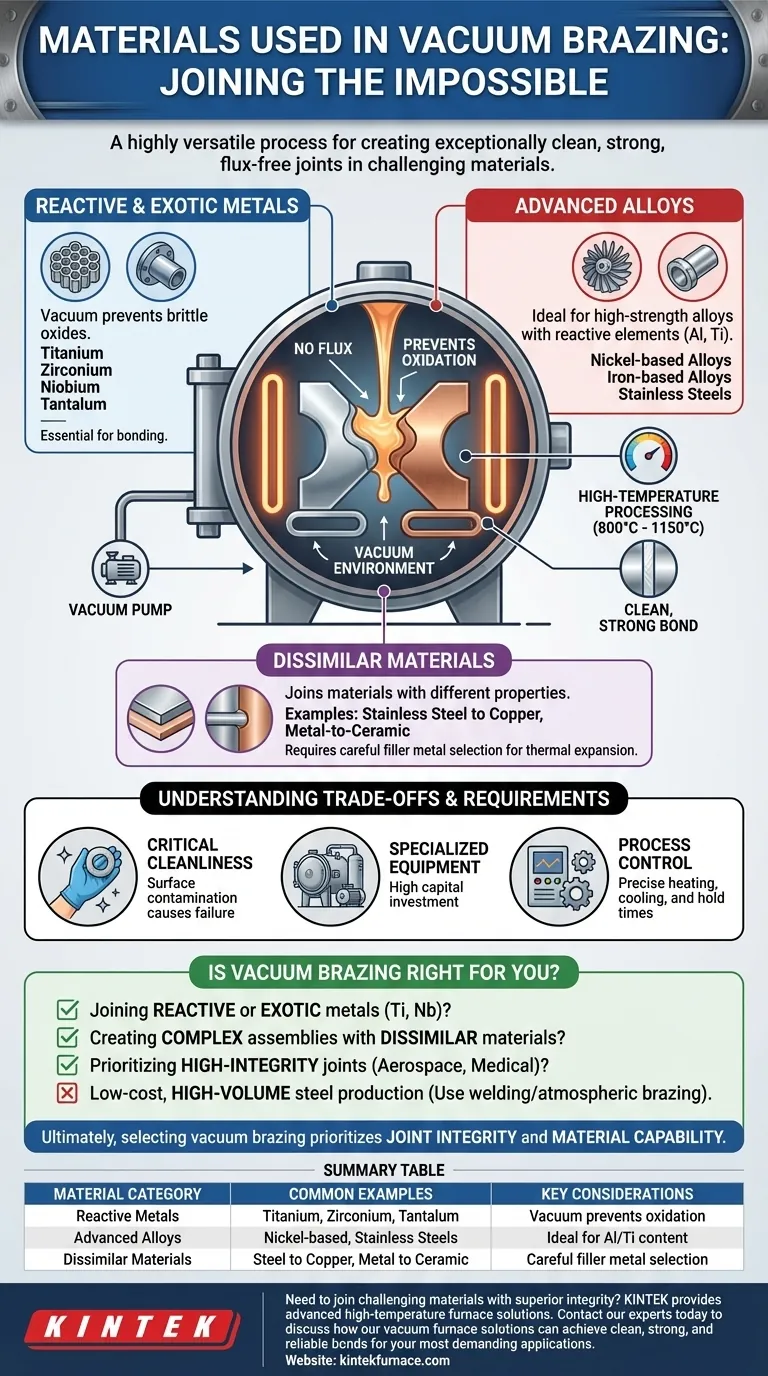

In short, vacuum brazing is a highly versatile process used to join an extensive range of materials that are often difficult or impossible to join with other methods. This includes high-performance metals like titanium and nickel alloys, refractory metals such as molybdenum and tantalum, and even dissimilar pairings like stainless steel to copper or metals to ceramics. The process relies on a carefully selected filler metal to create the bond in a high-vacuum environment.

The true advantage of vacuum brazing is not just the list of materials it can handle, but its ability to create exceptionally clean, strong, and flux-free joints. The vacuum itself acts as the critical element, preventing oxidation and enabling bonds of the highest integrity between challenging materials.

The Scope of Materials in Vacuum Brazing

Vacuum brazing is defined by its ability to handle materials that would be compromised by the presence of oxygen at high temperatures. This opens the door to a unique set of applications and material combinations.

High-Performance and Reactive Metals

Many advanced engineering materials are highly reactive with oxygen, especially when heated. A vacuum environment is essential for joining them.

This category includes exotic base metals such as titanium, zirconium, niobium, and tantalum. The vacuum prevents the formation of brittle oxides on their surfaces, which would otherwise inhibit a proper braze.

Advanced Alloys

The process is also ideal for modern, high-strength alloys that contain reactive elements.

These are typically nickel-based and iron-based alloys (including many stainless steels) that contain small but critical amounts of aluminum or titanium. These elements improve the alloy's properties but make them difficult to braze in a standard atmosphere.

The Challenge of Dissimilar Materials

One of the most significant capabilities of vacuum brazing is joining materials with different chemical and physical properties.

It can produce strong bonds between different metals, such as stainless steel and copper, or even create metal-to-ceramic assemblies. Success in these applications depends heavily on the careful selection of a filler alloy that can accommodate different rates of thermal expansion and wet both surfaces effectively.

Why the Vacuum is the Critical Element

While we focus on the metals being joined, the process environment is what makes the technology possible. In vacuum brazing, the vacuum is not passive; it is an active and essential component of the process.

Preventing Oxidation Without Flux

In traditional brazing, a chemical flux is used to clean the surfaces and prevent oxidation. This flux can become trapped in the joint, causing corrosion or creating a point of weakness.

Vacuum brazing eliminates the need for flux. By removing oxygen and other atmospheric gases from the furnace, the vacuum itself prevents oxidation. This allows the molten filler metal to wet the base materials cleanly, resulting in a stronger, more reliable, and cosmetically cleaner joint.

Enabling High-Temperature Processing

The process involves heating parts to temperatures often between 800°C and 1150°C—hot enough to melt the filler metal but not the base materials.

Holding the components at these temperatures in a vacuum protects them from thermal degradation and contamination, ensuring the material properties of the final assembly are not compromised.

Understanding the Trade-offs and Requirements

While powerful, vacuum brazing is a precise industrial process with demanding requirements. It is not a universally applicable solution for all joining tasks.

The Criticality of Cleanliness

Success is entirely dependent on meticulous preparation. Any surface contamination—such as oils, oxides, or even fingerprints—can prevent the filler metal from flowing correctly and result in a failed joint.

This necessitates thorough parts cleaning and often requires assembly to be performed in a dedicated, clean room environment to prevent re-contamination before the parts enter the furnace.

The Need for Specialized Equipment

Vacuum brazing requires a significant capital investment. The process relies on high-vacuum furnaces equipped with sophisticated pumping systems, including diffusion or turbomolecular pumps, to achieve the necessary low pressures.

This specialized equipment makes it a less accessible and more costly process compared to methods like torch brazing or conventional welding.

The Importance of Process Control

The heating rate, hold time at temperature, and cooling rate must be precisely controlled. These variables are critical for managing thermal stresses, particularly in dissimilar material joints, and ensuring the final component meets its required mechanical properties.

Is Vacuum Brazing Right for Your Application?

Choosing a joining method requires balancing the need for performance against cost and complexity. Use these points to guide your decision.

- If your primary focus is joining reactive or exotic metals (like titanium or niobium): Vacuum brazing is often the superior or only viable method to achieve a clean, strong bond.

- If your primary focus is creating complex assemblies with dissimilar materials (like metal-to-ceramic): This process offers unique capabilities, provided you can properly engineer the joint and select the correct filler alloy.

- If your primary focus is high-integrity joints for critical applications (aerospace, medical): The flux-free, low-contamination nature of vacuum brazed joints makes it an ideal choice where failure is not an option.

- If your primary focus is low-cost, high-volume production of simple steel parts: Other joining methods, such as welding or atmospheric brazing, are almost certainly more cost-effective.

Ultimately, selecting vacuum brazing is a decision to prioritize joint integrity and material capability above all else.

Summary Table:

| Material Category | Common Examples | Key Considerations |

|---|---|---|

| Reactive Metals | Titanium, Zirconium, Tantalum | Vacuum prevents oxidation; essential for bonding. |

| Advanced Alloys | Nickel-based, Stainless Steels | Ideal for alloys with aluminum/titanium content. |

| Dissimilar Materials | Steel to Copper, Metal to Ceramic | Requires careful filler metal selection for thermal expansion. |

Need to join challenging materials with superior integrity?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements like vacuum brazing.

Contact our experts today to discuss how our vacuum furnace solutions can achieve clean, strong, and reliable bonds for your most demanding applications.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- Why should nitrogen not be used as a cooling gas for titanium alloys in vacuum heat treatment? Avoid Catastrophic Failures

- How does a vacuum heat treatment furnace prevent contamination? Ensure Purity in High-Temperature Processes

- What does a vacuum furnace do? Achieve Superior Material Processing in a Pure Environment

- What is a vacuum furnace and what processes can it perform? Unlock Precision Heat Treatment Solutions

- Why is a high-vacuum environment necessary for sintering Cu/Ti3SiC2/C/MWCNTs composites? Achieve Material Purity