A remarkable range of high-technology sectors rely on vacuum furnaces to achieve material properties that are impossible in a standard atmosphere. Key industries include aerospace, automotive, medical, electronics, energy, and advanced research. These fields depend on the contamination-free, precisely controlled environment that only a vacuum can provide for critical processes like heat treatment, brazing, and sintering.

The common thread connecting these industries is not what they produce, but their non-negotiable requirement for materials with superior purity, strength, and structural integrity. Vacuum furnaces are the enabling technology for achieving this level of material perfection.

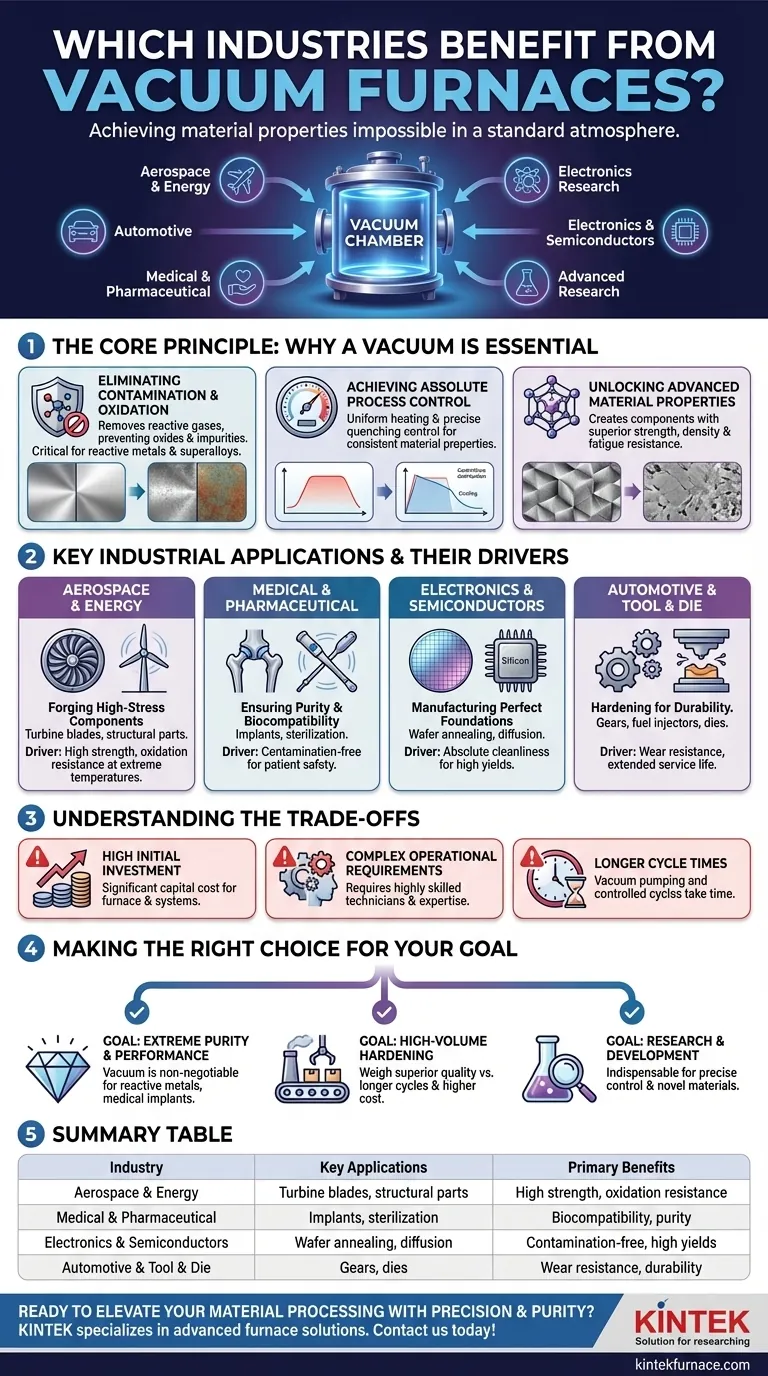

The Core Principle: Why a Vacuum is Essential

The fundamental benefit of a vacuum furnace is the removal of the atmosphere. By operating in an air-free or controlled-gas environment, it enables thermal processes that would otherwise fail due to oxidation and contamination.

Eliminating Contamination and Oxidation

Most conventional furnaces operate in the open air. The oxygen, nitrogen, and moisture present will react with a hot metal's surface, creating oxides and other impurities that compromise its integrity.

A vacuum furnace pumps out these reactive gases. This prevents unwanted chemical reactions, ensuring a clean, bright surface finish and preserving the material's intrinsic chemical purity. This is absolutely critical for reactive metals like titanium and superalloys used in jet engines.

Achieving Absolute Process Control

A vacuum is a superb insulator, which allows for exceptionally uniform heating and precise temperature control. This prevents hot or cold spots within the workload, ensuring every part achieves the exact same material properties.

Furthermore, the cooling (quenching) phase can be precisely managed by introducing high-purity inert gas at specific pressures and flow rates. This control over the cooling rate is a primary factor in determining the final hardness, strength, and microstructure of the material.

Unlocking Advanced Material Properties

The combination of purity and control allows manufacturers to create components with superior characteristics. Materials processed in a vacuum exhibit greater strength, density, and fatigue resistance.

This is essential for the synthesis of advanced materials like high-purity ceramics, metal-matrix composites, and even sintered biocompatible implants, which require flawless internal structures to function correctly.

Key Industrial Applications and Their Drivers

Different industries leverage vacuum furnaces to solve specific, high-stakes challenges where material failure is not an option.

Aerospace and Energy: Forging High-Stress Components

The aerospace and power generation sectors require components like turbine blades and structural airframe parts that operate under extreme heat and mechanical stress.

These parts are often made from nickel-based superalloys. Vacuum furnace heat treatment and brazing are mandatory to achieve the microstructural properties that prevent catastrophic failure at high temperatures.

Medical and Pharmaceutical: Ensuring Purity and Biocompatibility

For medical implants like artificial hips or dental posts, material purity is a matter of patient safety. Vacuum furnaces are used to process and sinter materials like titanium and specialized ceramics.

The contamination-free environment ensures the final implant is biocompatible and free from surface impurities that could cause an adverse reaction in the body. They are also used for sterilizing medical instruments where high heat is required without material degradation.

Electronics and Semiconductors: Manufacturing Perfect Foundations

The entire digital world is built on flawless silicon wafers. Vacuum furnaces are used for critical processes like annealing and diffusion during semiconductor manufacturing.

The absolute cleanliness of the vacuum environment prevents microscopic contaminants from ruining the wafer's delicate electronic pathways, ensuring high yields and reliable performance.

Automotive and Tool & Die: Hardening for Durability

In the automotive and tooling industries, the longevity of components like gears, fuel injectors, and stamping dies is paramount.

Vacuum heat treatment (case hardening) creates an extremely hard, wear-resistant surface while maintaining a more ductile core. This significantly extends the part's service life and prevents costly downtime.

Understanding the Trade-offs

While powerful, vacuum furnaces are a specialized solution with specific considerations. They are not a universal replacement for all thermal processing.

High Initial Investment

Vacuum furnaces represent a significant capital expenditure compared to their atmospheric counterparts. The cost includes the furnace itself, complex vacuum pump systems, and advanced control instrumentation.

Complex Operational Requirements

These are not simple "plug-and-play" machines. Operating a vacuum furnace requires highly skilled technicians who understand the interplay between vacuum levels, temperature profiles, and gas quenching dynamics.

Longer Cycle Times

The process of pumping a chamber down to a deep vacuum can be time-consuming. This, combined with controlled heating and cooling cycles, often results in longer overall process times compared to conventional furnaces, which can be a factor in high-volume production.

Making the Right Choice for Your Goal

Selecting vacuum processing is a strategic decision based on the required outcome.

- If your primary focus is extreme material purity and performance: Vacuum furnace processing is non-negotiable for reactive metals, superalloys, and critical medical implants.

- If your primary focus is high-volume hardening and tempering: A vacuum furnace offers superior quality, but you must weigh its longer cycle times and higher cost against the benefits over traditional atmosphere furnaces.

- If your primary focus is research and development: The precise control offered by vacuum furnaces makes them an indispensable tool for studying material behavior and creating novel composites and alloys.

Ultimately, adopting vacuum furnace technology is a decision to prioritize material perfection and performance over processing simplicity.

Summary Table:

| Industry | Key Applications | Primary Benefits |

|---|---|---|

| Aerospace & Energy | Turbine blades, structural parts | High strength, oxidation resistance |

| Medical & Pharmaceutical | Implants, sterilization | Biocompatibility, purity |

| Electronics & Semiconductors | Wafer annealing, diffusion | Contamination-free, high yields |

| Automotive & Tool & Die | Gears, dies | Wear resistance, durability |

Ready to elevate your material processing with precision and purity? KINTEK specializes in advanced high-temperature furnace solutions, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems. Leveraging our exceptional R&D and in-house manufacturing, we offer deep customization to meet your unique experimental needs in industries like aerospace, medical, and electronics. Contact us today to discuss how our tailored solutions can enhance your lab's efficiency and achieve superior results!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the significance of vacuum sintering in metal processing, and how do continuous vacuum furnaces facilitate it? Unlock High-Purity Metal Parts

- What factors are important in vacuum brazing? Achieve Flawless Joints with Precision Control

- What are the key material requirements for crucibles used in the vacuum distillation of aluminum-magnesium alloys? Ensure High-Purity Metal Separation

- How are vacuum furnaces utilized in additive manufacturing post-processing? Unlock High-Performance Metal Parts

- How does vacuum compare to other atmosphere control methods? Achieve Superior Purity and Simplicity

- What is the difference between a muffle furnace and a vacuum furnace? Choose the Right Heat for Your Process

- How does an industrial vacuum heat treatment furnace facilitate the diffusion step in the OBD process? Expert Insights

- Why must Graphene Oxide be dried in a vacuum at 60°C? Protect Your Nanomaterial Integrity