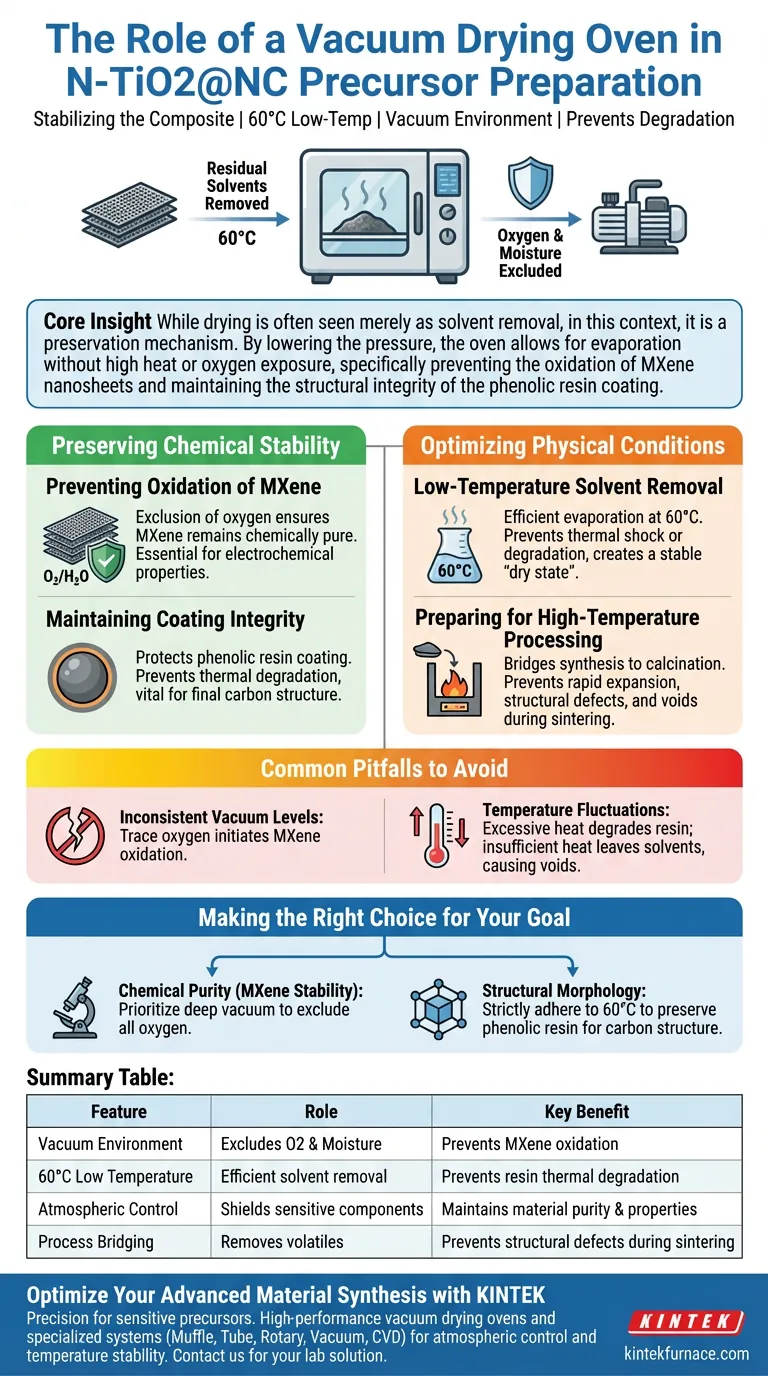

The role of a vacuum drying oven in the final stage of N-TiO2@NC precursor preparation is to stabilize the composite material. It functions by removing residual solvents at a controlled, low temperature of 60°C. Critically, it operates under a vacuum to exclude oxygen and moisture, which shields the sensitive chemical components from degradation before the next processing phase.

Core Insight While drying is often seen merely as solvent removal, in this context, it is a preservation mechanism. By lowering the pressure, the oven allows for evaporation without high heat or oxygen exposure, specifically preventing the oxidation of MXene nanosheets and maintaining the structural integrity of the phenolic resin coating.

Preserving Chemical Stability

Preventing Oxidation of MXene

The most critical function of the vacuum environment is the exclusion of oxygen. MXene nanosheets are highly susceptible to oxidation when exposed to air, especially during heating.

By processing the precursor in a vacuum, the oven ensures that the MXene component remains chemically pure. This preservation is essential for maintaining the material's intended electrochemical properties.

Maintaining Coating Integrity

The process protects the phenolic resin coating applied to the composite. High temperatures or oxidative environments could degrade this organic layer.

Maintaining the structural integrity of this coating is vital. It serves as the carbon source and structural framework during the subsequent high-temperature thermal processing steps.

Optimizing Physical Conditions

Low-Temperature Solvent Removal

The vacuum lowers the boiling point of solvents, allowing them to evaporate efficiently at just 60°C.

This low-temperature operation prevents thermal shock or degradation that might occur at higher drying temperatures. It ensures the material creates a stable "dry state" without altering its chemical composition.

Preparing for High-Temperature Processing

This drying stage is the bridge between synthesis and calcination. It ensures the precursor is free of volatile solvents that could cause rapid expansion or structural defects during sintering.

By delivering a dry, non-oxidized precursor, the vacuum oven sets the stage for uniform carbonization in the final thermal treatment.

Common Pitfalls to Avoid

Inconsistent Vacuum Levels

If the vacuum seal is compromised or the pressure is not sufficiently low, trace amounts of oxygen can enter the chamber. Even minor oxygen exposure at 60°C can initiate the oxidation of the MXene nanosheets, compromising the final performance of the N-TiO2@NC material.

Temperature Fluctuations

While 60°C is the target, significant deviations can be detrimental. Excessive heat may prematurely cure or degrade the phenolic resin, while insufficient heat may leave residual solvents trapped within the composite, leading to voids or cracks during the final high-temperature firing.

Making the Right Choice for Your Goal

To ensure the highest quality N-TiO2@NC precursors, prioritize the control of atmospheric conditions over speed.

- If your primary focus is Chemical Purity (MXene Stability): Ensure your vacuum system is capable of maintaining a deep vacuum to strictly exclude all oxygen and moisture during the cycle.

- If your primary focus is Structural Morphology: Strictly adhere to the 60°C limit to preserve the phenolic resin coating, as this defines the final carbon structure.

Success in this stage is defined not just by drying the material, but by freezing its chemical state to ensure uniformity in the final product.

Summary Table:

| Feature | Role in N-TiO2@NC Preparation | Key Benefit |

|---|---|---|

| Vacuum Environment | Excludes oxygen and moisture | Prevents oxidation of sensitive MXene nanosheets |

| 60°C Low Temperature | Efficient solvent removal at low boiling points | Prevents thermal degradation of phenolic resin |

| Atmospheric Control | Shields sensitive chemical components | Maintains material purity and electrochemical properties |

| Process Bridging | Removes volatile solvents before calcination | Prevents structural defects and voids during sintering |

Optimize Your Advanced Material Synthesis with KINTEK

Precision is non-negotiable when handling sensitive precursors like MXene and phenolic resins. KINTEK provides high-performance vacuum drying ovens and specialized high-temperature systems designed to deliver the rigorous atmospheric control and temperature stability your research demands.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to protect your chemical integrity and ensure structural morphology.

Ready to elevate your material quality? Contact us today to find the perfect solution for your lab.

Visual Guide

References

- Hui Zhang, ZhengMing Sun. Phase Engineering of <scp>MXene</scp> Derivatives Via Molecular Design for High‐Rate Sodium‐Ion Batteries. DOI: 10.1002/eem2.12692

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering and Brazing Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

People Also Ask

- Why is a high-vacuum heat treatment furnace necessary for vacuum annealing HEA coatings? Ensure Chemical Stability

- What is the purpose of using a vacuum drying oven for composite filter cakes? Ensure defect-free hot pressing results.

- Why is a vacuum system or controlled cooling often required after ceramic sintering? Prevent Failure and Cracking

- What is a vacuum furnace and what is its primary function? Achieve Purity and Precision in High-Temperature Processing

- What are the advantages of a mesh belt brazing furnace vs vacuum? Optimize High-Volume Stainless Steel Production

- Why is a vacuum drying oven necessary for chitosan and iron sludge particles? Expert Structural Preservation Guide

- How do the drying conditions in a vacuum drying oven affect NiS2 electrode quality? Optimize Your Battery Performance

- Why are the Sn-flux method and vacuum sealing necessary for the synthesis of NdMn2Ge2 single crystal materials?