Precise thermal regulation is non-negotiable. A vacuum system or controlled cooling device is required during the post-sintering phase to strictly manage the rate of temperature reduction. This controlled process is the only effective way to release mechanical stresses accumulated within the ceramic at high temperatures, thereby preventing structural failure.

The primary function of controlled cooling is to prevent thermal shock. By modulating the temperature drop, manufacturers avoid the formation of micro-cracks, ensuring the structural integrity of large or complex ceramic components.

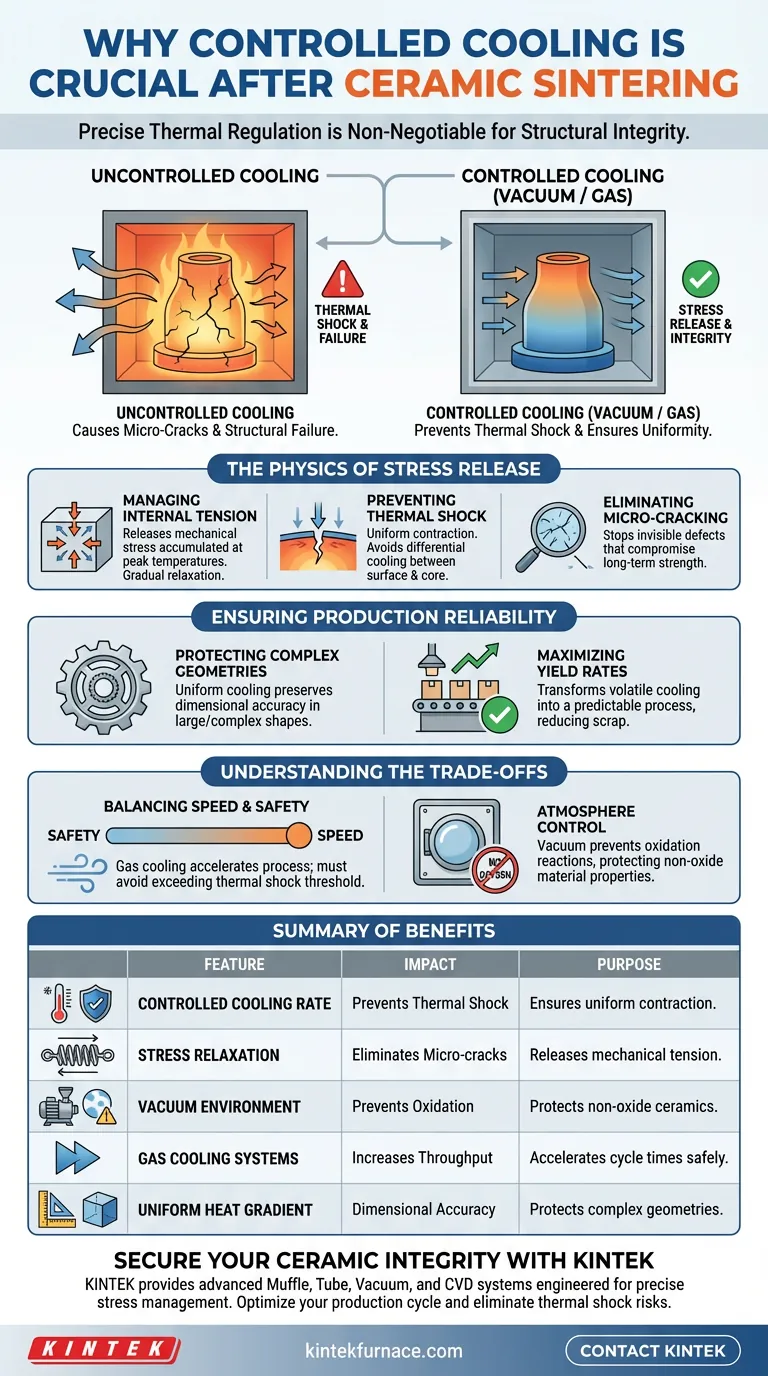

The Physics of Stress Release

Managing Internal Tension

Ceramics accumulate significant mechanical stress when held at peak sintering temperatures.

If the material is allowed to cool naturally or unevenly, these internal stresses become trapped. A controlled cooling system gradually lowers the temperature, allowing the material to relax and release these stresses harmlessly.

Preventing Thermal Shock

Rapid temperature changes trigger thermal shock, a leading cause of catastrophic failure in ceramics.

This phenomenon occurs when the surface cools faster than the core, creating differential contraction. Controlled cooling ensures the temperature gradient remains uniform throughout the part, effectively preventing this destructive reaction.

Eliminating Micro-Cracking

Even if a part does not fracture immediately, uncontrolled cooling often generates micro-cracks.

These microscopic defects compromise the material's long-term strength and performance. By precisely managing the cooling curve, the formation of these invisible but critical flaws is stopped at the source.

Ensuring Production Reliability

Protecting Complex Geometries

Standard cooling methods are often insufficient for large-sized or complex-shaped components.

These parts have varying cross-sections that cool at different rates naturally. A controlled system forces a uniform reduction in temperature, preserving the dimensional accuracy of intricate designs.

Maximizing Yield Rates

The cooling phase is a common point of failure in ceramic manufacturing.

Implementing a vacuum or controlled cooling system directly correlates to a high yield rate. It transforms a volatile cooling step into a predictable process, significantly reducing the number of scrapped parts.

Understanding the Trade-offs

Balancing Speed and Safety

While the primary goal is safety, modern vacuum furnaces can employ gas cooling to accelerate the process.

This allows for faster cycle times, increasing production throughput. However, this must be balanced carefully; increasing the cooling rate too aggressively risks reintroducing thermal shock, specifically in denser materials.

Atmosphere Control

While the primary reference highlights stress management, the vacuum environment plays a secondary protective role.

Maintaining a vacuum during the initial high-temperature cooling phase prevents oxidation reactions, particularly in non-oxide ceramics. It ensures that the material properties preserved during sintering are not degraded as the part cools down.

Making the Right Choice for Your Goal

To optimize your post-sintering process, assess your specific constraints:

- If your primary focus is structural integrity: Prioritize a slow, programmable cooling curve to fully release mechanical stresses and eliminate micro-cracking risks.

- If your primary focus is production throughput: Utilize gas cooling capabilities to shorten cycle times, provided the rate does not exceed the material's thermal shock threshold.

Controlled cooling is not merely a final step; it is the safeguard that solidifies the quality of the entire sintering cycle.

Summary Table:

| Feature | Impact on Ceramic Quality | Purpose in Cooling Phase |

|---|---|---|

| Controlled Cooling Rate | Prevents Thermal Shock | Ensures uniform contraction between core and surface. |

| Stress Relaxation | Eliminates Micro-cracks | Releases mechanical tension accumulated at peak temperatures. |

| Vacuum Environment | Prevents Oxidation | Protects material properties in non-oxide ceramics. |

| Gas Cooling Systems | Increases Throughput | Accelerates cycle times without compromising structural integrity. |

| Uniform Heat Gradient | Dimensional Accuracy | Protects complex geometries from warping or fracturing. |

Secure Your Ceramic Integrity with KINTEK

Don't let uncontrolled cooling ruin your high-performance ceramics. KINTEK provides industry-leading thermal solutions, including advanced Muffle, Tube, Vacuum, and CVD systems, specifically engineered for precise stress management and thermal regulation.

Backed by expert R&D and world-class manufacturing, our customizable lab high-temperature furnaces empower researchers and manufacturers to achieve higher yield rates and flawless structural results. Contact KINTEK today to discover how our tailored cooling technologies can optimize your production cycle and eliminate the risk of thermal shock.

Visual Guide

References

- Wencke Mohring, Christiane Stephan‐Scherb. High-Temperature Corrosion of High- and Medium-Entropy Alloys CrMnFeCoNi and CrCoNi Exposed to a Multi-Oxidant Atmosphere H2O–O2–SO2. DOI: 10.1007/s44210-023-00026-8

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

People Also Ask

- Why is a vacuum environment essential when using a Spark Plasma Sintering (SPS) furnace for Ti64-Si3N4-ZrO2? Achieve Optimal Density & Purity

- What additional processes can a vacuum heat treatment furnace carry out? Unlock Advanced Material Processing

- What is the function of specialty insulation in a vacuum furnace? Unlock Efficiency & Quality

- What is the first step in the vacuum sintering process? Master the Key to High-Performance Parts

- Why is a laboratory high-temperature furnace equipped with a high-vacuum system essential for metal-slag reactions?

- What role does a vacuum annealing furnace play in the final heat treatment of Ti-5Al-2.5Sn-0.2C alloys? Master Carbon Management

- What is the necessity of using a high-vacuum drying oven? Preserve Electrospun Fiber Morphology and Integrity

- What are the advantages of using a vacuum oven for delithiated NCM powders? Optimize Your Battery Material Purity