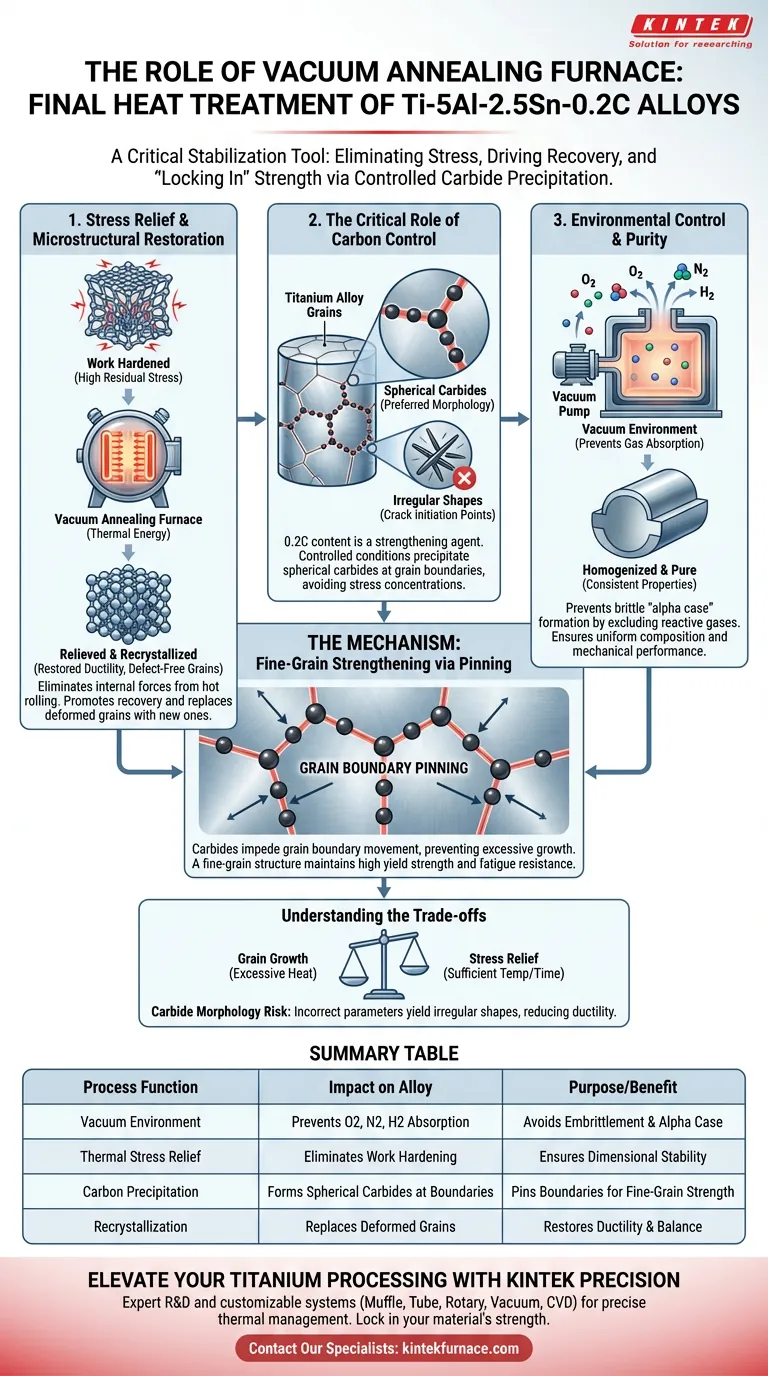

The vacuum annealing furnace acts as a critical stabilization tool in the final processing of Ti-5Al-2.5Sn-0.2C alloys. Its primary function following hot rolling is to eliminate residual stresses caused by work hardening while driving microstructural recovery and recrystallization. Crucially, for this specific carbon-bearing alloy, the furnace environment engineers the microstructure to "lock in" strength through the controlled precipitation of carbides.

Core Takeaway While standard annealing relieves stress, the vacuum process is essential for Ti-5Al-2.5Sn-0.2C to prevent atmospheric embrittlement and manage carbon behavior. The treatment stabilizes alpha grains and precipitates spherical carbides at grain boundaries, which pin the structure to prevent grain growth and maintain fine-grain strengthening.

Stress Relief and Microstructural Restoration

The mechanical processing of titanium alloys, such as hot rolling, introduces significant internal energy. The vacuum annealing furnace serves as the corrective mechanism to restore equilibrium.

Eliminating Residual Stresses

Hot rolling induces work hardening, leaving the material with high levels of residual stress. If left untreated, these stresses can lead to dimensional instability or premature failure. The furnace provides the thermal energy required to relax the atomic structure and eliminate these internal forces.

Recovery and Recrystallization

Beyond simple stress relief, the thermal cycle promotes microstructural recovery. This process allows the deformed grains to reorganize. As the treatment continues, recrystallization occurs, replacing the deformed grains with a new set of defect-free grains, restoring the alloy's ductility.

The Critical Role of Carbon Control

For the specific composition of Ti-5Al-2.5Sn-0.2C, the "0.2C" (carbon) content is not incidental; it is a strengthening agent that requires precise thermal management.

Formation of Spherical Carbides

The annealing process facilitates the diffusion of carbon atoms. Under controlled conditions, these atoms precipitate to form spherical carbides. The spherical morphology is preferred over irregular shapes, as it is less likely to act as a stress concentration point that could initiate cracks.

The Grain Boundary Pinning Effect

These carbides do not form randomly; they tend to precipitate at grain boundaries. Once positioned there, they serve a "pinning" function. They physically impede the movement of grain boundaries, effectively acting as anchors.

Maintaining Fine-Grain Strengthening

By inhibiting the movement of grain boundaries, the carbides prevent the grains from growing excessively large during the heat treatment. This preserves a fine-grain structure. In metallurgy, finer grains generally equate to higher yield strength and better fatigue resistance, a phenomenon known as fine-grain strengthening.

Environmental Control and Purity

Titanium is highly reactive at elevated temperatures. The "vacuum" aspect of the furnace is as important as the heat itself.

Preventing Gas Absorption

Titanium has a high affinity for oxygen, nitrogen, and hydrogen. Absorbing these gases creates a brittle surface layer (often called an "alpha case") and degrades mechanical properties. The vacuum environment prevents this reaction, eliminating the need for extensive post-treatment surface machining.

Homogenization

The vacuum furnace provides a uniform thermal field. This promotes the diffusion of solute atoms, reducing elemental segregation within the alloy. This ensures that the chemical composition—and therefore the mechanical performance—is consistent throughout the entire cross-section of the part.

Understanding the Trade-offs

While vacuum annealing is beneficial, it requires precise parameter control to avoid adverse effects.

Carbide Morphology Risks

The benefit of the 0.2% carbon addition relies entirely on the shape of the carbides. If the annealing temperature or time is incorrect, carbides may form irregular or acicular (needle-like) shapes rather than spherical ones. Irregular carbides can reduce ductility and act as crack initiation sites.

Grain Growth vs. Stress Relief

There is a delicate balance between temperature and time. Higher temperatures allow for faster stress relief and recrystallization but increase the driving force for grain growth. While carbides help pin the boundaries, excessive heat can eventually overcome this pinning effect, leading to coarse grains and reduced strength.

Making the Right Choice for Your Goal

When designing the heat treatment cycle for Ti-5Al-2.5Sn-0.2C, your specific end-use requirements should dictate your process parameters.

- If your primary focus is Maximum Strength: Prioritize parameters that maximize the formation of spherical grain-boundary carbides to leverage the fine-grain strengthening effect.

- If your primary focus is Material Purity: Ensure the vacuum level is maintained strictly (e.g., preventing oxidation) to avoid embrittlement, particularly if the part has thin cross-sections where surface contamination is critical.

The ultimate goal of this process is to produce a stress-free, chemically stable alloy where carbon is utilized as a strengthening mechanism rather than a defect generator.

Summary Table:

| Process Function | Impact on Ti-5Al-2.5Sn-0.2C Alloy | Purpose/Benefit |

|---|---|---|

| Vacuum Environment | Prevents absorption of O2, N2, and H2 | Avoids embrittlement and "alpha case" formation |

| Thermal Stress Relief | Eliminates work hardening from hot rolling | Ensures dimensional stability and prevents failure |

| Carbon Precipitation | Forms spherical carbides at grain boundaries | Pins grain boundaries to maintain fine-grain strength |

| Recrystallization | Replaces deformed grains with defect-free ones | Restores material ductility and mechanical balance |

Elevate Your Titanium Processing with KINTEK Precision

Precise thermal management is the difference between a high-performance alloy and a brittle failure. At KINTEK, we understand the delicate balance of carbide morphology and grain growth in Ti-5Al-2.5Sn-0.2C alloys.

Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique laboratory or industrial needs. Whether you require high-vacuum environments to prevent atmospheric embrittlement or precise temperature control for fine-grain strengthening, our team provides the technology to lock in your material's strength.

Ready to optimize your heat treatment results?

Contact our specialists today to discuss your custom furnace solution.

Visual Guide

References

- Agnieszka Szkliniarz, W. Szkliniarz. Microstructure and Properties of Ti-5Al-2.5Sn Alloy with Higher Carbon Content. DOI: 10.3390/coatings15020224

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What safety concerns are mentioned regarding the vacuum chamber? Avoid Catastrophic Implosion Risks

- What are the advantages of using an industrial vacuum oven for biomass powders? Maximize Quality & Chemical Stability

- What are the primary benefits of vacuum heat treatment technology? Achieve Superior Metallurgical Control and Quality

- How do vacuum-based systems like PLD and Magnetron Sputtering contribute to superconducting thin films? Expert Guide

- How do vacuum furnace systems facilitate accelerated aging tests for SDSS2507? Ensure Precision in Neutron Scattering

- What factors should be considered when choosing between a low vacuum and high vacuum furnace? Optimize Your Heat Treatment Process

- What are the heating and cooling capabilities of a vacuum furnace? Unlock Superior Thermal Processing