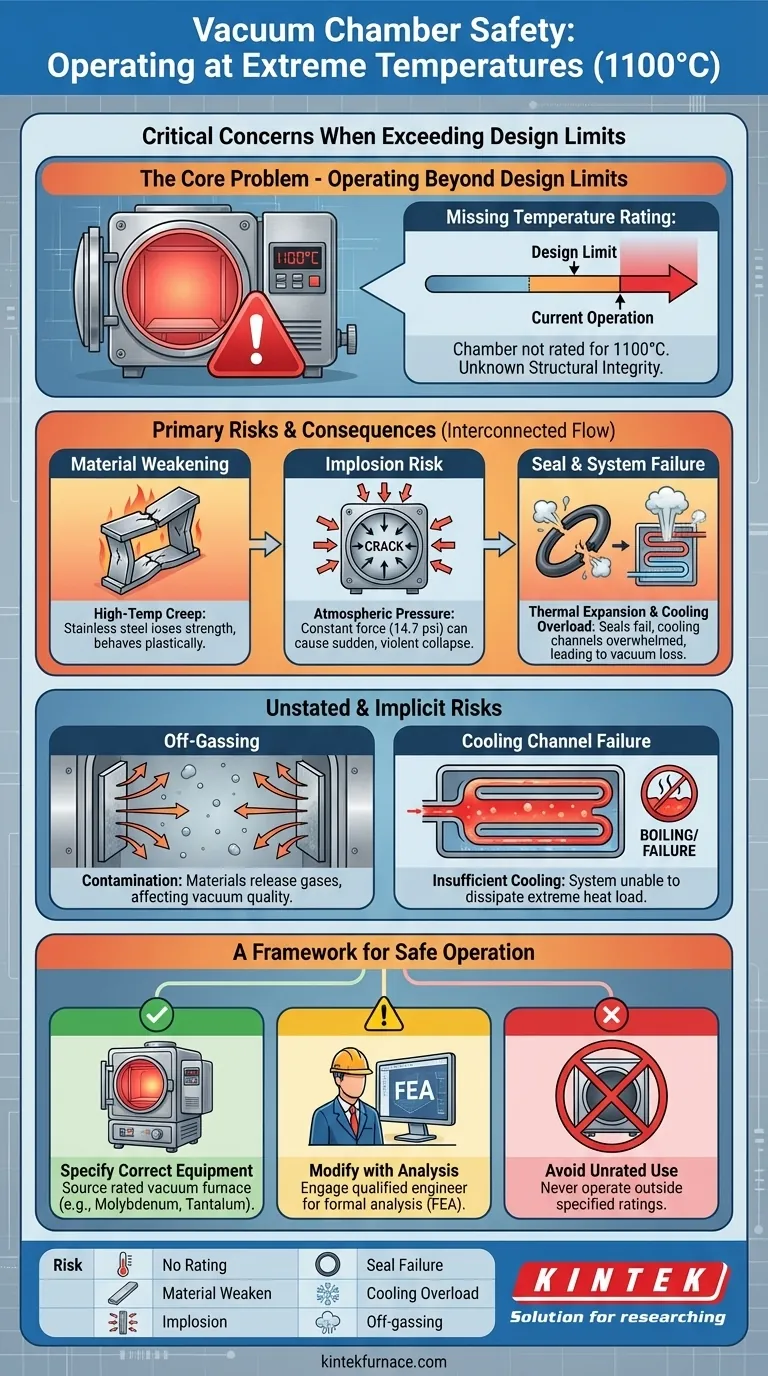

The most critical safety concern mentioned is that the stainless steel vacuum chamber is being considered for use at 1100°C despite not being rated for any specific temperature. This lack of a formal rating means its structural integrity under the combined stress of high temperature and external atmospheric pressure is completely unknown, creating a significant and unacceptable risk.

The core issue is the intention to operate equipment far beyond its designed or verified capabilities. A vacuum chamber is a pressure vessel, and heating it to extreme temperatures severely weakens its material strength, creating a serious risk of catastrophic structural failure and implosion.

The Core Problem: Operating Beyond Design Limits

The scenario described involves pushing a piece of equipment into a performance envelope for which it was not designed. The desire to reach 1100°C in a vacuum is a common goal in materials science, but it requires purpose-built equipment.

The Missing Temperature Rating

A temperature rating is not just a suggestion; it is a guarantee from the manufacturer that the chamber can safely withstand specific conditions.

Without this rating, you are operating blindly. There is no verified data on how the chamber's materials, welds, and geometry will behave at 1100°C.

The Impact of High Temperature on Materials

Stainless steel, while robust at room temperature, loses a significant amount of its structural strength at 1100°C. This process, known as high-temperature creep, makes the material behave more like a plastic than a rigid solid.

The original use for glow discharge suggests the system was designed for plasma processes, which may generate heat but are fundamentally different from operating a bulk furnace at such an extreme temperature.

The Force of Vacuum (Implosion Risk)

A vacuum does not "suck." Instead, the full pressure of the outside atmosphere (approximately 14.7 pounds per square inch, or 1 ton per square foot) is constantly pushing on every surface of the chamber.

When the chamber's material is weakened by intense heat, it may no longer be able to resist this immense, constant force, leading to a sudden and violent collapse known as an implosion.

Unstated Risks and Critical Considerations

While the references are brief, an expert must consider the implied risks that arise from the stated conditions. These are consequences that logically follow from the combination of high heat and vacuum.

Thermal Expansion and Seal Failure

Heating the chamber to 1100°C will cause the steel to expand significantly. This expansion creates immense stress on welds and flanges.

Most vacuum seals, such as elastomer O-rings, cannot survive anywhere near this temperature. Even if the chamber itself were to hold, the seals would likely fail, causing a complete loss of vacuum.

The Purpose of Cooling Channels

The reference to "integral cooling channels" is a critical clue. These channels are designed to flow a liquid (like water) to remove heat and keep the chamber walls and, most importantly, the seals at a safe operating temperature.

However, these channels are likely designed to dissipate a certain amount of heat—a thermal load far lower than what a 1100°C internal furnace would generate. They would almost certainly be overwhelmed, leading to boiling of the coolant and a failure to protect the chamber walls and seals.

Material Off-gassing

At extreme temperatures under vacuum, all materials, including the stainless steel itself, begin to release trapped gases in a process called off-gassing.

This phenomenon works directly against the vacuum pumps, making it difficult or impossible to maintain the desired low pressure. It also contaminates the internal environment, potentially ruining the experiment or process.

A Framework for Safe Operation

To move forward, you must shift from adapting inadequate equipment to specifying the correct equipment for the job. Your operational goal dictates the necessary engineering requirements.

- If your primary focus is safety: Never use a pressure vessel or vacuum chamber outside of its manufacturer-specified temperature and pressure ratings. The risk of catastrophic implosion is too high.

- If your primary focus is achieving 1100°C under vacuum: You must source a high-temperature vacuum furnace system specifically designed and rated for this purpose, which will include appropriate materials (e.g., molybdenum, tantalum, or ceramics) and insulation.

- If you are considering modifying existing equipment: You must engage a qualified mechanical or materials engineer to perform a formal analysis, such as Finite Element Analysis (FEA), to determine if the chamber can be safely repurposed and what modifications would be required.

Ultimately, ensuring the structural integrity of the chamber through proper engineering and certified ratings is the non-negotiable foundation for any successful and safe high-temperature vacuum process.

Summary Table:

| Safety Concern | Key Details |

|---|---|

| Lack of Temperature Rating | Chamber not rated for 1100°C, unknown structural integrity |

| Material Weakening | Stainless steel loses strength at high temperatures, risking deformation |

| Implosion Risk | External atmospheric pressure can cause violent collapse |

| Seal Failure | High heat damages seals, leading to vacuum loss |

| Cooling Channel Overload | Integral cooling may be insufficient, causing system failure |

| Off-gassing | Materials release gases, contaminating the vacuum environment |

Ensure your lab's safety and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with reliable products like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets unique experimental requirements, helping you avoid risks and achieve optimal results. Contact us today to discuss your needs and get a tailored solution!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What safety and reliability features are incorporated into a vertical tube furnace? Ensuring Safe, Consistent High-Temp Processing

- What safety measures are essential when operating a lab tube furnace? A Guide to Preventing Accidents

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab