At its core, a vacuum furnace offers exceptionally uniform heating across a vast temperature range, typically from 800 to 3,000 °C (1,500 to 5,400 °F), and provides rapid, controlled cooling. This combination allows for precise manipulation of material properties in a highly pure environment, free from the oxidation and contamination common in traditional furnaces.

The true capability of a vacuum furnace is not just its ability to get hot or cold, but its power to precisely control the entire thermal cycle—heating, soaking, and cooling—in an inert environment to achieve superior material quality and performance.

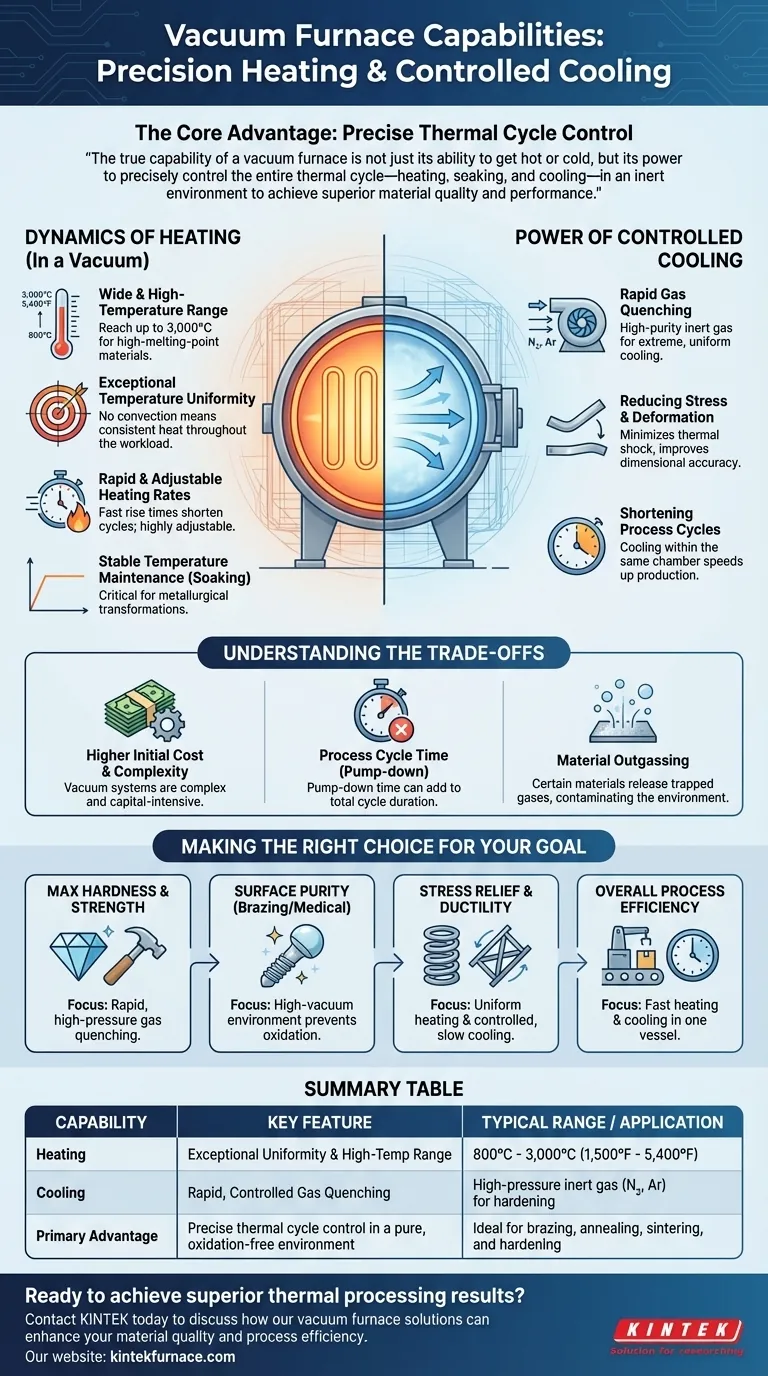

The Dynamics of Heating in a Vacuum

A vacuum furnace's heating process is defined by its precision, uniformity, and speed. The absence of air ensures that heat transfer is clean and efficient, primarily through radiation.

Wide and High-Temperature Range

Vacuum furnaces are engineered to operate across a broad spectrum of temperatures. Many models can easily reach 2000°C, making them suitable for processing high-melting-point metals and advanced alloys that are beyond the scope of conventional atmosphere furnaces.

Exceptional Temperature Uniformity

Because heating occurs in a vacuum, there are no convection currents to create hot or cold spots. This results in highly uniform temperature distribution throughout the workload, ensuring every part of a component receives the exact same thermal treatment for consistent, predictable results.

Rapid and Adjustable Heating Rates

Modern vacuum furnaces feature chambers with low thermal mass compared to older refractory-lined furnaces. This design allows for fast temperature rise times, which significantly shortens the overall process cycle and improves production efficiency. The heating rate is also highly adjustable to meet specific process requirements.

Stable Temperature Maintenance

For processes like annealing, sintering, or brazing, holding a precise temperature for a set period (soaking) is critical. Vacuum furnaces excel at maintaining a constant and stable temperature, which is crucial for achieving the desired metallurgical transformations.

The Power of Controlled Cooling

The cooling, or quenching, phase is just as critical as the heating phase. A vacuum furnace provides unparalleled control over this process to lock in desired material properties.

Rapid Gas Quenching

After the heating cycle, the furnace chamber is backfilled with a high-purity inert gas, such as nitrogen or argon. High-velocity blowers then circulate this gas through the workload, enabling extremely rapid and uniform cooling. This process is essential for hardening metals and achieving specific microstructures.

Reducing Stress and Deformation

The controlled and uniform nature of gas quenching helps minimize thermal shock and material stress. This leads to less part distortion compared to harsher liquid quenching methods, improving the quality and dimensional accuracy of the final product.

Shortening Process Cycles

The ability to cool parts down quickly within the same chamber where they were heated dramatically reduces the overall cycle time. This efficiency is a significant advantage in a production environment.

Understanding the Trade-offs

While powerful, vacuum furnaces are not a universal solution. Understanding their limitations is key to making an informed decision.

Higher Initial Cost and Complexity

Vacuum systems, including pumps and controls, make these furnaces more complex and carry a higher capital cost than standard atmosphere furnaces. They also require specialized knowledge for operation and maintenance.

Process Cycle Time Considerations

Although heating and cooling rates are fast, the time required to pump the chamber down to the required vacuum level can add to the total cycle time. For some low-value, high-volume parts, this may be less efficient than a continuous belt furnace.

Material Outgassing

The vacuum environment itself can be a limitation. Certain materials can release trapped gases (outgassing) when heated under vacuum, which can contaminate the furnace environment and interfere with the process.

Making the Right Choice for Your Goal

To determine if a vacuum furnace is the right tool, align its capabilities with your primary objective.

- If your primary focus is maximum hardness and strength: The rapid, high-pressure gas quenching capability is the most critical feature.

- If your primary focus is surface purity for brazing or medical implants: The high-vacuum environment's ability to prevent oxidation is non-negotiable.

- If your primary focus is stress relief and ductility (annealing): The combination of uniform heating and controlled, slower cooling rates provides superior results.

- If your primary focus is overall process efficiency: The ability to complete an entire heat-treat cycle in one vessel with fast heating and cooling shortens lead times.

Ultimately, a vacuum furnace provides a level of environmental and thermal control that is essential for producing high-quality, high-performance components.

Summary Table:

| Capability | Key Feature | Typical Range/Application |

|---|---|---|

| Heating | Exceptional Uniformity & High-Temp Range | 800°C to 3,000°C (1,500°F to 5,400°F) |

| Cooling | Rapid, Controlled Gas Quenching | High-pressure inert gas (N₂, Ar) for hardening |

| Primary Advantage | Precise thermal cycle control in a pure, oxidation-free environment | Ideal for brazing, annealing, sintering, and hardening |

Ready to achieve superior thermal processing results?

KINTEK's advanced vacuum furnaces are engineered to deliver the precise heating and rapid, uniform cooling your high-value materials demand. Leveraging our exceptional R&D and in-house manufacturing, we provide robust solutions for aerospace, medical, and advanced alloy applications.

Our product line, including Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental and production requirements.

Contact KINTEK today to discuss how our vacuum furnace solutions can enhance your material quality and process efficiency.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

People Also Ask

- What is the purpose of a 1400°C heat treatment for porous tungsten? Essential Steps for Structural Reinforcement

- Why is a high vacuum essential for Ti-6Al-4V sintering? Protect Your Alloys from Embrittlement

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What are the benefits of using a high-temperature vacuum furnace for the annealing of ZnSeO3 nanocrystals?

- What tasks does a high-temperature vacuum sintering furnace perform for PEM magnets? Achieve Peak Density