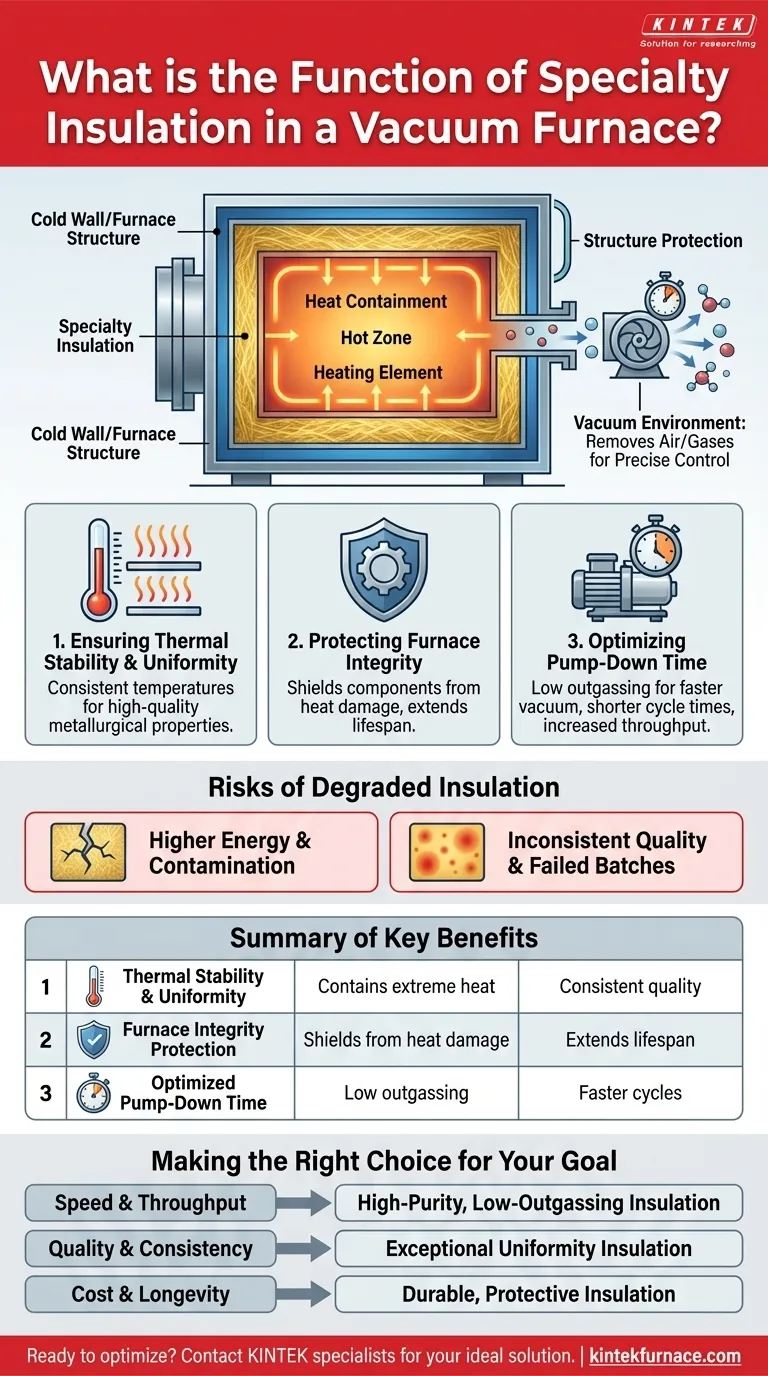

At its core, specialty insulation in a vacuum furnace performs three critical functions: it contains the extreme heat within the "hot zone" for thermal stability, it protects the rest of the furnace structure from heat damage, and it directly influences the speed and efficiency of the vacuum process itself. These functions are essential for achieving the consistent, high-quality results expected from vacuum heat treatment.

The function of specialty insulation goes beyond simple heat containment. It is an active performance component that dictates the furnace's efficiency, process speed, and the final quality of the treated material by ensuring thermal uniformity and minimizing gas contamination.

The Purpose of the Vacuum Environment

Before examining the insulation, it's vital to understand why a vacuum is necessary. A vacuum furnace creates a controlled environment by removing air and other gases from a sealed chamber before heating begins.

Preventing Oxidation and Contamination

The primary goal is to eliminate reactive gases like oxygen. This prevents unwanted chemical reactions such as oxidation and contamination, which is crucial when processing sensitive metals and ceramics.

Achieving Precise Process Control

The vacuum allows for extremely precise and uniform heating. With no air to interfere with heat transfer, the furnace can execute complex heat treatment cycles like annealing, sintering, or quenching with a high degree of repeatability.

The Three Core Functions of Specialty Insulation

Specialty insulation is what enables the furnace to perform these tasks effectively. It isn't just a passive barrier; it's fundamental to the furnace's operation.

Ensuring Thermal Stability and Uniformity

The most obvious function of insulation is to keep the intense heat generated by the heating elements contained within the designated hot zone. This allows the furnace to reliably reach and maintain its target temperature with minimal energy loss.

This thermal containment ensures that the material being treated is heated uniformly, which is critical for achieving the desired metallurgical or ceramic properties across the entire part.

Protecting Furnace Integrity

The temperatures inside a hot zone can be extreme. The specialty insulation acts as a shield, protecting the outer furnace chamber (the "cold wall"), seals, and other sensitive components from thermal damage.

Without effective insulation, the structural integrity of the entire furnace would be compromised, leading to premature failure and costly repairs.

Optimizing Pump-Down Time

A less intuitive but critical function is the insulation's impact on vacuum performance. All materials, including insulation, can trap air, moisture, and other gases. When heated, they release these gases in a process called outgassing.

High-quality specialty insulation is designed for low outgassing. This means it releases very few trapped gases during the heating cycle, allowing the vacuum pumps to evacuate the chamber faster and achieve a deeper vacuum. This directly translates to shorter cycle times and increased throughput.

Understanding the Trade-offs

The choice and condition of your furnace insulation are not minor details; they have direct consequences on your entire operation.

The Cost of Degraded Insulation

Over time, all insulation degrades. When it does, its thermal efficiency drops, forcing the furnace to consume more energy to maintain temperature.

Degraded insulation also becomes a source of contamination. It can absorb more moisture and contaminants when the furnace is open to the atmosphere, leading to significant outgassing and dramatically longer pump-down times.

The Risk of Process Inconsistency

If insulation fails to provide uniform heat containment, you will create hot and cold spots within the furnace. This thermal inconsistency leads directly to inconsistent product quality, failed batches, and wasted resources.

Making the Right Choice for Your Goal

The insulation system is directly tied to your operational objectives.

- If your primary focus is process speed and throughput: You need high-purity, low-outgassing insulation to minimize pump-down time and shorten cycles.

- If your primary focus is product quality and consistency: Your priority is insulation that delivers exceptional thermal uniformity to guarantee repeatable, high-quality results.

- If your primary focus is operational cost and longevity: You require durable insulation that protects furnace components from heat damage and minimizes energy consumption over its lifetime.

Ultimately, viewing specialty insulation as a core performance component is the key to unlocking the full potential of your vacuum furnace.

Summary Table:

| Function | Key Benefit | Impact on Process |

|---|---|---|

| Thermal Stability & Uniformity | Contains extreme heat in the hot zone | Ensures consistent, high-quality material properties |

| Furnace Integrity Protection | Shields cold wall and components from heat damage | Extends furnace lifespan and reduces repair costs |

| Optimized Pump-Down Time | Low outgassing for faster vacuum achievement | Increases throughput and shortens cycle times |

Ready to optimize your vacuum furnace performance? The right specialty insulation is critical for achieving thermal uniformity, process speed, and product consistency. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD furnace systems, all customizable for your unique needs. Let our specialists help you select the ideal insulation solution for your goals—contact us today to discuss your application!

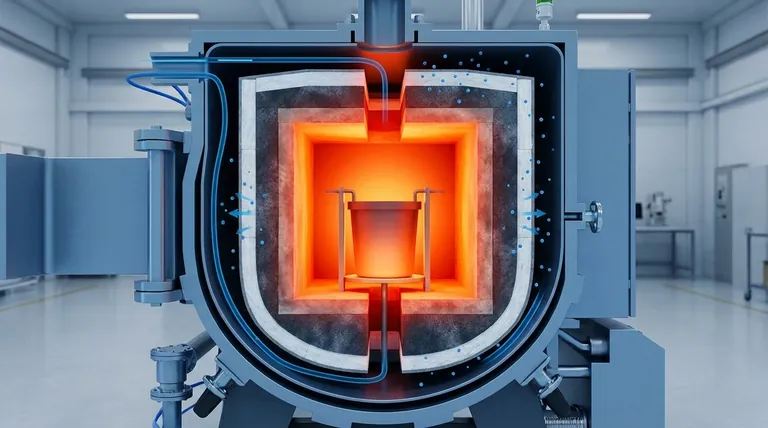

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion