The primary purpose of using a vacuum drying oven is to efficiently remove residual moisture from composite filter cakes at reduced temperatures before they are subjected to hot pressing. This process is critical for preventing the formation of structural defects and protecting the chemical stability of the composite matrix.

Core Insight: The vacuum environment lowers the boiling point of liquids, allowing moisture to evaporate without exposing the material to damaging heat levels. This creates a defect-free precursor that can withstand the rigors of hot pressing without degrading or developing internal voids.

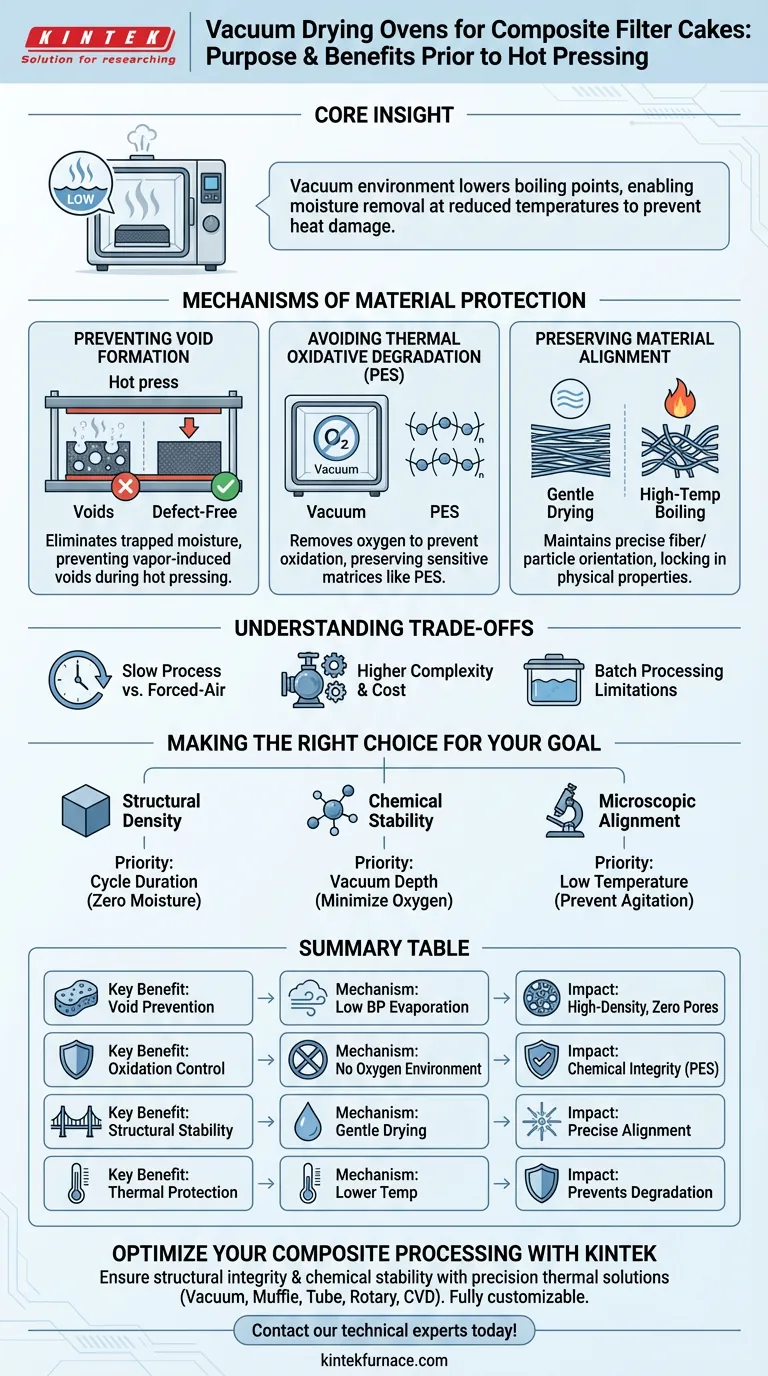

Mechanisms of Material Protection

Preventing Void Formation

The most immediate risk during hot pressing is trapped moisture. If a filter cake contains residual water or solvent when it enters a high-temperature press, that liquid instantly vaporizes.

This rapid vaporization creates internal pressure, resulting in pores or voids within the composite. Vacuum drying eliminates this moisture beforehand, ensuring the final material remains dense and structurally sound.

Avoiding Thermal Oxidative Degradation

Composite matrices, specifically those using polyethersulfone (PES), are sensitive to high temperatures in the presence of air. Standard drying methods can lead to thermal oxidative degradation, where the polymer chain breaks down.

By operating in a vacuum, oxygen is removed from the chamber. This allows the material to dry without oxidizing, preserving the chemical integrity of the PES matrix.

Preserving Material Alignment

Composite filter cakes often rely on a specific internal alignment of fibers or particles. High-temperature drying or aggressive boiling can disrupt this delicate structure.

Vacuum drying is a gentler process that stabilizes the material. It ensures the initial alignment remains intact, locking in the material's intended physical properties before the final consolidation step.

Understanding the Trade-offs

Process Speed vs. Material Quality

While vacuum drying ensures higher quality, it is generally a slower process compared to forced-air convection drying. The rate of heat transfer in a vacuum is lower, meaning the cycle time to reach total dryness may be longer.

Equipment Complexity

Vacuum drying requires more sophisticated equipment, including vacuum pumps and sealed chambers. This introduces higher maintenance requirements and capital costs compared to standard laboratory ovens.

Batch Processing Limitations

Vacuum ovens typically operate as batch processes rather than continuous lines. This can create a bottleneck in high-throughput manufacturing environments, requiring careful scheduling to match the cadence of the hot press.

Making the Right Choice for Your Goal

To determine how strictly you should control the vacuum drying parameters, consider your specific performance targets:

- If your primary focus is Structural Density: Prioritize the duration of the drying cycle to ensure zero residual moisture, as even trace amounts will cause voids during hot pressing.

- If your primary focus is Chemical Stability: Prioritize the depth of the vacuum to minimize oxygen presence, ensuring the PES matrix suffers no oxidative degradation.

- If your primary focus is Microscopic Alignment: Focus on maintaining a low temperature throughout the drying phase to prevent any thermal agitation that could disturb particle orientation.

Proper preparation in the vacuum oven is the defining factor between a high-performance composite and a flawed component.

Summary Table:

| Key Benefit | Mechanism in Vacuum Oven | Impact on Final Composite |

|---|---|---|

| Void Prevention | Removes moisture/solvents at low boiling points | High-density structure with zero internal pores |

| Oxidation Control | Eliminates oxygen from the drying environment | Preserves chemical integrity of sensitive matrices like PES |

| Structural Stability | Gentle drying prevents thermal agitation | Maintains precise fiber and particle alignment |

| Thermal Protection | Lower temperature evaporation | Prevents polymer chain breakdown and degradation |

Optimize Your Composite Processing with KINTEK

Ensure the structural integrity and chemical stability of your high-performance materials with precision thermal solutions. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Vacuum ovens, Muffle, Tube, Rotary, and CVD systems, all of which are fully customizable to meet your unique laboratory or industrial requirements.

Don't let residual moisture or oxidative degradation compromise your results. Contact our technical experts today to find the perfect drying solution for your composite manufacturing workflow!

Visual Guide

References

- Farooq Ahmad, Abdul Aal Zuhayr Al-Khazaal. Machine Learning-assisted Prediction and Optimization of Exergy Efficiency and Destruction of Cumene Plant under Uncertainty. DOI: 10.48084/etasr.6654

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How does the ultra-low oxygen environment of vacuum sintering affect titanium composites? Unlock Advanced Phase Control

- What role do vacuum furnaces play in the semiconductor industry? Essential for High-Purity Processing and Yield

- What are the advantages of multi-chamber continuous vacuum furnaces? Boost Efficiency in High-Volume Production

- Why is graphite material advantageous for vacuum furnace fixturing? Boost Efficiency and Precision

- What are the key requirements for a vacuum tempering furnace's cooling system? Ensure Precise Control for Superior Metallurgical Results

- How does a high-precision vacuum aging furnace control precipitation in superalloys? Engineering Gamma Prime Phases

- Why is low-temperature calcination in a vacuum furnace necessary for Yb:CaF2 nanopowders? Achieve Optical Perfection

- Why is it necessary to maintain a high vacuum for PrVSb3 single crystal preparation? Ensure Purity and Stoichiometry