At its core, a vacuum tempering furnace requires a rapid and highly controllable cooling system. The primary components are a water cooling circuit with a pressure exceeding 0.2 MPa and adjustable flow, often supplemented by a forced cooling mechanism that uses inert gas to quickly lower the workpiece temperature.

The purpose of a furnace cooling system is not simply to make things cold. Its true function is to provide precise, repeatable control over the cooling rate, which is what determines the final metallurgical properties of the workpiece while simultaneously protecting the furnace from thermal damage.

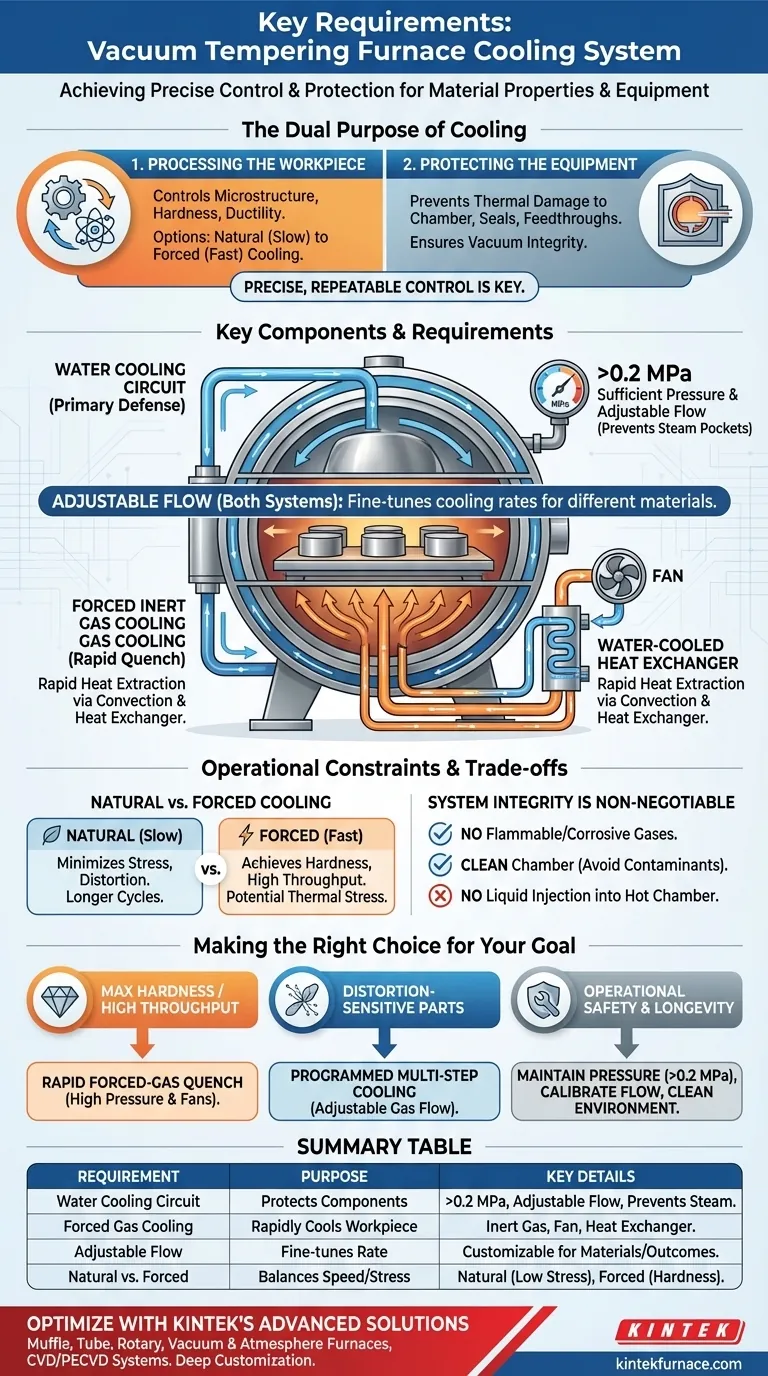

The Dual Purpose of Cooling in Vacuum Tempering

Understanding the cooling system begins with recognizing its two distinct but equally critical responsibilities: processing the workpiece and protecting the equipment.

Achieving Desired Material Properties

The rate at which a metal part cools after tempering directly influences its final microstructure, hardness, and ductility. The cooling system must be capable of managing this process with precision.

Different applications demand different cooling rates. This is why systems offer options ranging from natural cooling (slowly cooling within the vacuum) to forced cooling, which actively removes heat.

Protecting Furnace Integrity

Vacuum furnaces operate at extremely high temperatures. A robust cooling system is essential for maintaining the structural integrity of the furnace itself.

The water cooling circuit continuously removes heat from the furnace chamber walls, door seals, and power feedthroughs. Without this, these components would quickly degrade or fail, leading to vacuum leaks and costly repairs.

Key Components and Their Requirements

A modern vacuum furnace cooling system is an integrated design where each part serves a specific function. Failure in one area compromises the entire process.

The Water Cooling Circuit

This is the furnace's primary defense against heat. Water circulates through jackets and tubes built into the furnace shell to absorb and carry away thermal energy.

The requirement for water pressure greater than 0.2 MPa ensures sufficient flow and contact to cool the hot zones effectively. Inadequate pressure can lead to localized boiling (steam pockets), which dramatically reduces cooling efficiency and can cause hot spots on the furnace body.

Forced Cooling with Inert Gas

To cool the workpiece rapidly, an inert gas like argon or nitrogen is injected into the hot zone after the tempering cycle is complete.

This gas absorbs heat from the parts via convection. A powerful fan then circulates the hot gas through a water-cooled heat exchanger, which removes the heat from the gas before it is blown back over the parts. This creates a highly efficient closed loop for rapid heat extraction.

The Need for Adjustable Flow

The requirement for adjustable flow applies to both the water and the inert gas. This control is what allows the operator to fine-tune the cooling rate.

Different materials, part thicknesses, and desired metallurgical outcomes require different cooling profiles. Adjustable flow gives the furnace the flexibility to handle a wide range of jobs correctly.

Understanding the Operational Constraints

Properly running a vacuum furnace requires respecting its operational limits, especially concerning the cooling system and chamber environment.

Natural vs. Forced Cooling Trade-offs

Forced cooling is fast and ideal for achieving specific hardness in many steels, but the rapid temperature change can induce thermal stress or distortion in complex or delicate parts.

Natural cooling is very slow and minimizes stress, but it extends cycle times and may not be suitable for alloys that require a faster quench to achieve their target properties.

System Integrity is Non-Negotiable

The cooling system is a lifeline. The furnace must be operated in an environment free of flammable or corrosive gases that could damage the equipment or create a hazard.

Furthermore, the furnace chamber must be kept clean. Contaminants like oil or residue can vaporize during a cycle and interfere with both the vacuum and the cooling process. Direct injection of any liquid into the hot chamber is strictly prohibited.

Making the Right Choice for Your Goal

To ensure consistent, high-quality results, you must match your cooling strategy to your specific processing objective.

- If your primary focus is achieving maximum hardness or high throughput: A rapid forced-gas quench using a system with high-pressure water and powerful circulation fans is essential.

- If your primary focus is processing distortion-sensitive or complex parts: A programmed, multi-step cooling cycle with adjustable gas flow is necessary to manage thermal stress.

- If your primary focus is operational safety and equipment longevity: Rigorously maintaining water pressure above 0.2 MPa, ensuring adjustable flow controllers are calibrated, and keeping a clean furnace environment are your most critical tasks.

Ultimately, mastering the cooling process is fundamental to achieving control and repeatability in your vacuum tempering operations.

Summary Table:

| Requirement | Purpose | Key Details |

|---|---|---|

| Water Cooling Circuit | Protects furnace components | Pressure >0.2 MPa, prevents steam pockets, ensures efficient heat removal |

| Forced Cooling with Inert Gas | Rapidly cools workpiece | Uses argon/nitrogen, fan circulation, heat exchanger for controlled cooling rates |

| Adjustable Flow | Fine-tunes cooling rate | Allows customization for different materials, thicknesses, and metallurgical outcomes |

| Natural vs. Forced Cooling | Balances speed and stress | Natural cooling minimizes distortion; forced cooling achieves hardness and high throughput |

Optimize your vacuum tempering with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise cooling system performance to meet your unique experimental needs, enhancing material properties and furnace longevity. Contact us today to discuss how we can support your lab's success!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability