In medical device manufacturing, a vacuum environment is indispensable for creating an ultra-clean, controlled space. This prevents contamination and unwanted chemical reactions, ensuring that materials and components meet the stringent safety, purity, and performance standards required for patient care. It is the key to producing everything from biocompatible implants to high-precision surgical tools.

The fundamental role of a vacuum is to remove atmospheric gases and contaminants. This single action protects material integrity at high temperatures, guarantees the purity required for biocompatibility, and enables specialized manufacturing processes that are physically impossible in a normal atmosphere.

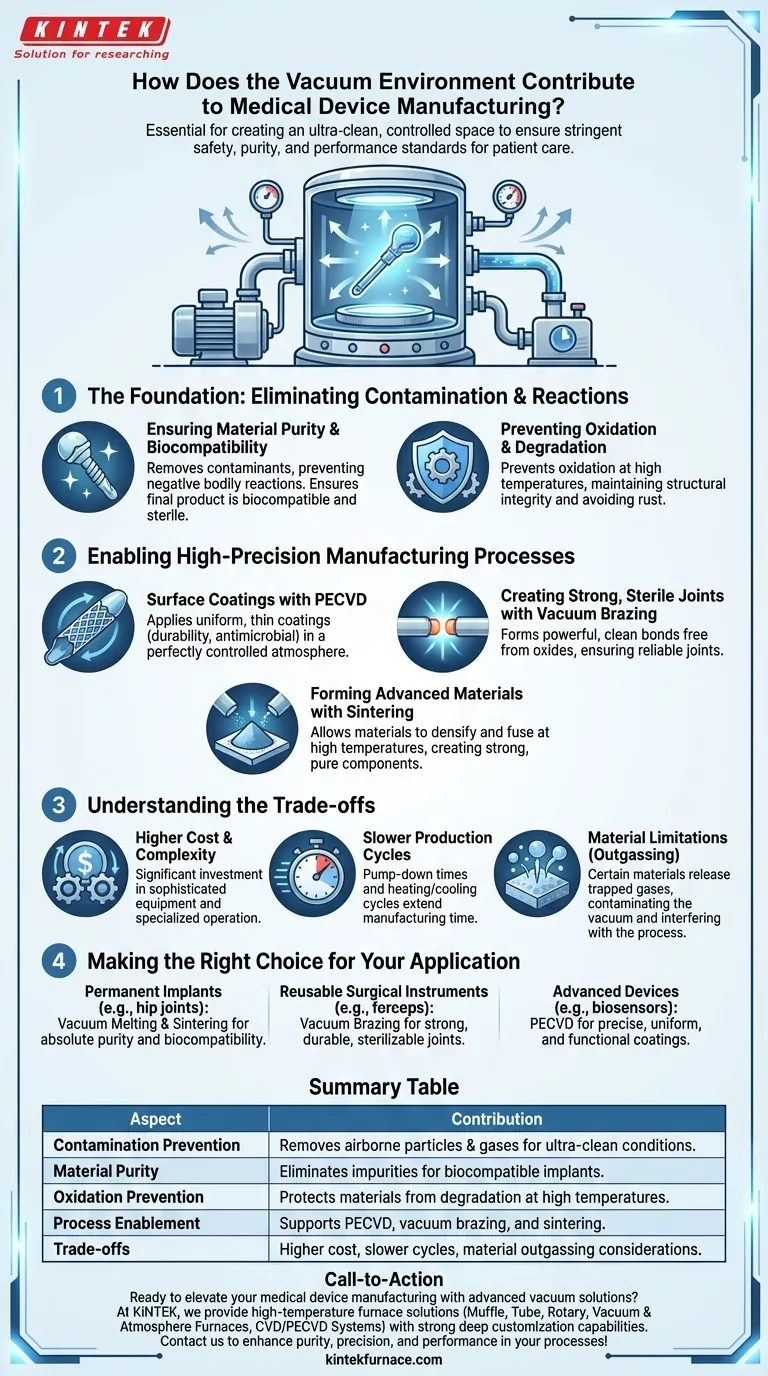

The Foundation: Eliminating Contamination and Reactions

The primary function of a vacuum is to create a void, removing the air and, more importantly, the reactive gases and airborne particles within it. This seemingly simple step has profound implications for material quality.

Ensuring Material Purity and Biocompatibility

When creating materials for implants, any impurity can trigger a negative reaction from the human body. Vacuum melting and processing remove contaminants that would otherwise get trapped in the material.

This process is critical for ensuring the final product is biocompatible—meaning it will not cause a harmful immunological response—and sterile from the moment of its creation.

Preventing Oxidation and Degradation

Many advanced manufacturing techniques, such as melting, brazing, and sintering, require extremely high temperatures. In a normal atmosphere, these temperatures would cause materials to react with oxygen, leading to oxidation (like rust).

Oxidation weakens the material, compromises its structural integrity, and can introduce impurities. A vacuum environment eliminates the oxygen, allowing materials to be processed at high temperatures without degradation.

Enabling High-Precision Manufacturing Processes

Beyond just protecting materials, a vacuum enables specific manufacturing techniques that are core to modern medical technology. The absence of an atmosphere changes the rules of physics, allowing for outcomes not otherwise achievable.

Surface Coatings with Plasma Deposition (PECVD)

Processes like Plasma-Enhanced Chemical Vapor Deposition (PECVD) are used to apply thin, highly uniform coatings to medical devices. These coatings can improve durability, reduce friction, or provide antimicrobial properties.

A vacuum is essential for PECVD because it provides a perfectly controlled atmosphere where plasma-activated chemical reactions can occur on a device's surface without interference from external contaminants, ensuring a flawless and uniform coating.

Creating Strong, Sterile Joints with Vacuum Brazing

Vacuum brazing is a superior method for joining components to create complex instruments or implants. The process melts a filler metal to form a powerful bond between two parts.

Performing this in a vacuum ensures the joint is perfectly clean and free from oxides that would create weak spots. This results in high-quality, reliable joints essential for the safety and longevity of surgical instruments and diagnostic equipment.

Forming Advanced Materials with Sintering

Sintering is the process of forming a solid, dense material from a powder using heat and pressure. Using a vacuum for this process, often called hot-pressing, offers a unique advantage.

Under vacuum, materials can be heated to temperatures that would cause them to vaporize at normal atmospheric pressure. This allows the material particles to densify and fuse together more effectively, creating exceptionally strong and pure components for implants.

Understanding the Trade-offs

While vacuum processing provides unmatched quality, it is a specialized technique with inherent trade-offs that must be considered.

Higher Cost and Complexity

Vacuum furnaces and their associated pumps are sophisticated pieces of equipment. They represent a significant capital investment and require specialized knowledge to operate and maintain, increasing overall manufacturing costs.

Slower Production Cycles

Achieving and maintaining a high-quality vacuum is not instantaneous. The time required to pump down the chamber, run the heating and cooling cycle, and vent the system makes vacuum processes inherently slower than their atmospheric counterparts.

Material Limitations

Certain materials can experience outgassing under vacuum, where trapped gases within the material itself are released. This can contaminate the vacuum environment and interfere with the process, requiring careful material selection and pre-treatment.

Making the Right Choice for Your Application

The decision to use a vacuum process depends entirely on the device's requirements for safety, purity, and performance.

- If your primary focus is permanent implants (e.g., hip joints, dental implants): Vacuum melting and sintering are non-negotiable to achieve the absolute material purity and biocompatibility required for long-term patient safety.

- If your primary focus is reusable surgical instruments (e.g., forceps, endoscopes): Vacuum brazing is critical for creating strong, crevice-free joints that are durable and can be reliably sterilized after every use.

- If your primary focus is advanced devices with functional surfaces (e.g., coated stents, biosensors): Vacuum deposition processes like PECVD are essential for applying the precise, uniform, and sterile coatings that define the device's function.

Ultimately, leveraging a vacuum environment is a deliberate engineering choice to eliminate risk and guarantee performance where it matters most.

Summary Table:

| Aspect | Contribution |

|---|---|

| Contamination Prevention | Removes airborne particles and gases to ensure ultra-clean conditions. |

| Material Purity | Eliminates impurities for biocompatible implants and sterile components. |

| Oxidation Prevention | Protects materials from degradation at high temperatures. |

| Process Enablement | Supports PECVD coatings, vacuum brazing, and sintering for advanced devices. |

| Trade-offs | Higher cost, slower cycles, and material outgassing considerations. |

Ready to elevate your medical device manufacturing with advanced vacuum solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with high-temperature furnace solutions. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to precisely meet your unique experimental needs. Contact us today to discuss how our tailored solutions can enhance purity, precision, and performance in your processes!

Visual Guide

Related Products

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What industrial and research applications are tube furnaces used for? Unlock Precise Thermal Processing Solutions

- What is the function of high-vacuum encapsulated quartz tubes for Ce2(Fe, Co)17? Ensure Phase Purity and Stability

- What is the primary function of a vacuum-sealed quartz tube in MnBi2Te4 growth? Ensure High-Purity Crystal Synthesis

- What is the working principle of a vacuum tube furnace? Master Precise High-Temperature Processing

- What is the significance of porcelain furnaces in academic and scientific research? Unlock Innovation with Precise High-Temperature Control