In high-stakes manufacturing, vacuum sintering furnaces are indispensable for creating components with the highest possible purity, strength, and precision. They achieve this by processing materials in a high-temperature, vacuum-sealed environment, which prevents the contamination and chemical reactions that occur in the open air. This controlled atmosphere is the key to unlocking superior material properties that are impossible to achieve with conventional heating methods.

The true importance of a vacuum furnace isn't just the heat it provides, but the atmosphere it removes. By eliminating reactive gases like oxygen, these furnaces create an ultra-pure environment, allowing materials to bond and densify without compromising their structural or chemical integrity.

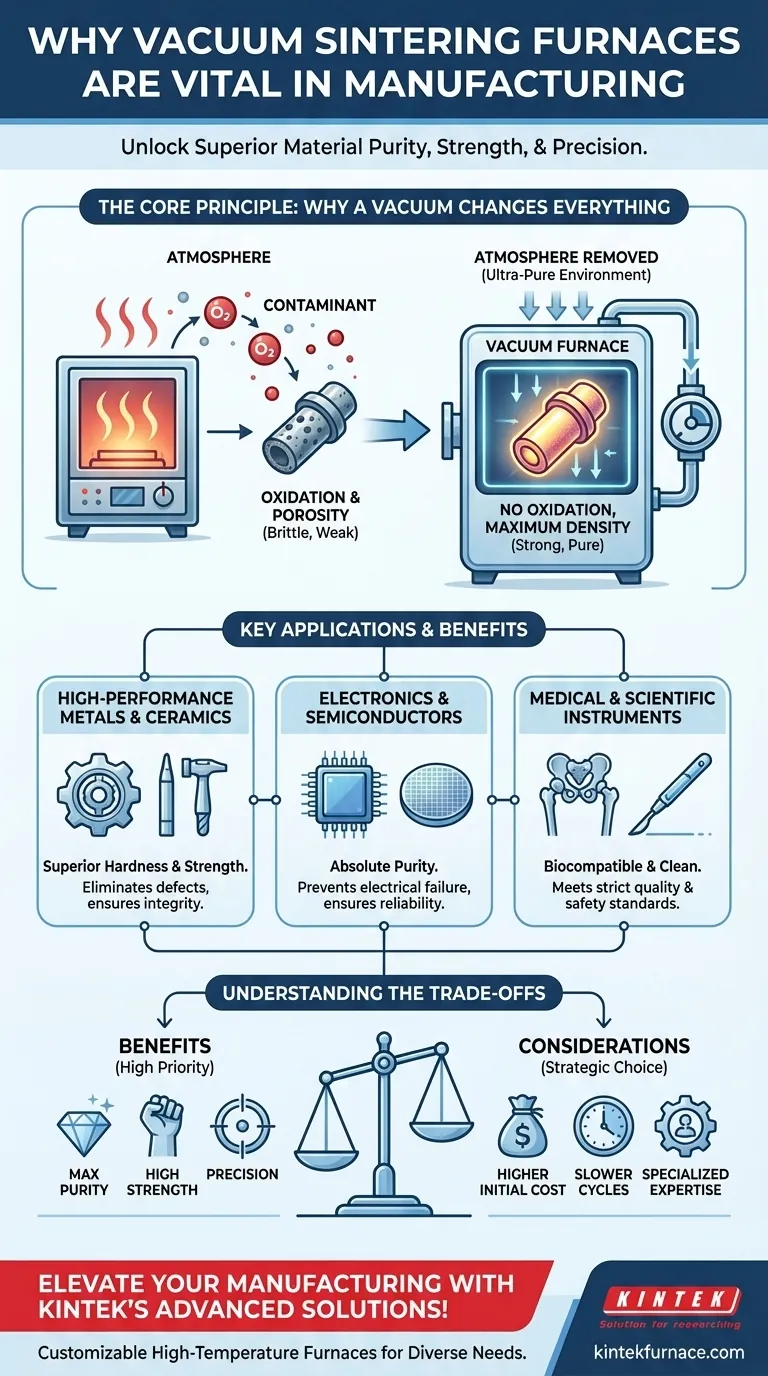

The Core Principle: Why a Vacuum Changes Everything

The primary function of a vacuum furnace is to remove the atmosphere from the processing chamber. This seemingly simple act has profound implications for material science at high temperatures.

Eliminating Oxidation and Contamination

At high temperatures, most advanced materials—especially metals—readily react with oxygen and other gases in the air. This process, known as oxidation, can create brittle, weak layers that degrade the final product's performance.

A vacuum furnace pumps out these reactive gases, creating a pristine environment. This prevents oxidation and ensures the material's surface and internal structure remain pure and chemically unaltered.

Achieving Maximum Material Density

Sintering is the process of compacting and forming a solid mass of material by heat without melting it to the point of liquefaction. During this process, tiny voids or pores can get trapped within the material.

The vacuum actively helps remove gases trapped in these pores, allowing the material particles to bond more tightly. This results in a final product with significantly higher density, which directly correlates to greater strength, hardness, and wear resistance.

Enabling High-Purity Material Development

For industries like electronics and medicine, even microscopic impurities can cause catastrophic failures. A vacuum furnace provides the ideal cleanroom environment for producing these materials.

By removing atmospheric contaminants, it ensures that materials like semiconductor wafers or medical-grade titanium meet the most stringent purity standards required for their application.

Key Applications Driven by Vacuum Technology

The ability to create pure, dense, and strong materials makes vacuum furnaces critical in several leading-edge industries.

For High-Performance Metals and Ceramics

Components for aerospace, automotive, and industrial tooling demand exceptional mechanical properties. Vacuum sintering is used to produce parts from cemented carbides, titanium alloys, and advanced ceramics.

The resulting components exhibit superior hardness and strength because the process eliminates the internal defects and brittle oxide layers that act as failure points.

For Electronics and Semiconductors

The manufacturing of semiconductors and integrated circuits requires almost absolute purity. Vacuum furnaces are essential for processes like wafer diffusion and chip packaging.

Even trace amounts of oxygen or moisture can alter the electrical properties of a semiconductor, rendering it useless. The controlled atmosphere of a vacuum furnace is non-negotiable for reliable production.

For Medical and Scientific Instruments

Materials used inside the human body, such as medical implants, must be biocompatible and free from any contaminants. Vacuum processing ensures these devices meet strict quality and safety standards.

Similarly, high-precision instrument components are often processed in a vacuum to guarantee dimensional stability and material integrity over time.

Understanding the Trade-offs and Considerations

While powerful, vacuum sintering is a specialized process with specific trade-offs that must be weighed against its benefits.

Higher Initial Cost and Complexity

Vacuum furnaces are sophisticated machines with complex pumping systems, seals, and controls. This results in a significantly higher initial investment compared to standard atmospheric furnaces.

Slower Cycle Times

Achieving a deep vacuum and executing a precisely controlled heating and cooling cycle takes more time. Pumping down the chamber, processing, and cooling under vacuum is inherently slower than open-air processes.

Maintenance and Operational Expertise

The vacuum systems, including pumps and seals, require regular, specialized maintenance to ensure performance and prevent leaks. Operating these furnaces effectively also demands a higher level of technical skill and training.

Making the Right Choice for Your Goal

Selecting the right furnace technology depends entirely on the requirements of your final product. A vacuum furnace is not always the necessary choice, but for certain goals, it is the only choice.

- If your primary focus is maximum material strength and density: Vacuum sintering is essential for removing porosity and preventing the brittle oxide layers that compromise mechanical integrity.

- If your primary focus is absolute material purity for electronics or medical use: The ultra-clean environment of a vacuum furnace is non-negotiable to eliminate contaminants that cause device failure or biocompatibility issues.

- If your primary focus is cost-effective, high-volume production of less sensitive materials: A conventional atmospheric furnace is often the more practical and economical solution.

Ultimately, choosing a vacuum furnace is a strategic decision to prioritize material quality and performance above all else.

Summary Table:

| Key Aspect | Benefit |

|---|---|

| Eliminates Oxidation | Prevents contamination and ensures material purity |

| Increases Density | Enhances strength, hardness, and wear resistance |

| Enables High Purity | Meets strict standards for electronics and medical devices |

| Applications | Aerospace, automotive, electronics, medical implants |

| Trade-offs | Higher cost, slower cycles, requires expertise |

Elevate your manufacturing with KINTEK's advanced vacuum sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace expertise. Our product line includes Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental needs. Contact us today to discuss how our tailored solutions can enhance purity, strength, and precision in your processes!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What are the primary application fields for box furnaces and vacuum furnaces? Choose the Right Furnace for Your Process

- Why are some vacuum furnaces backfilled with a partial pressure gas? Prevent Alloy Depletion in High-Temp Processes

- What is the role of the temperature control system in a vacuum furnace? Achieve Precise Material Transformations

- Why are vacuum furnaces considered important in various industries? Unlock Superior Material Performance

- What is the function of a vacuum sintering furnace in CoNiCrAlY coatings? Repairing Cold-Sprayed Microstructures