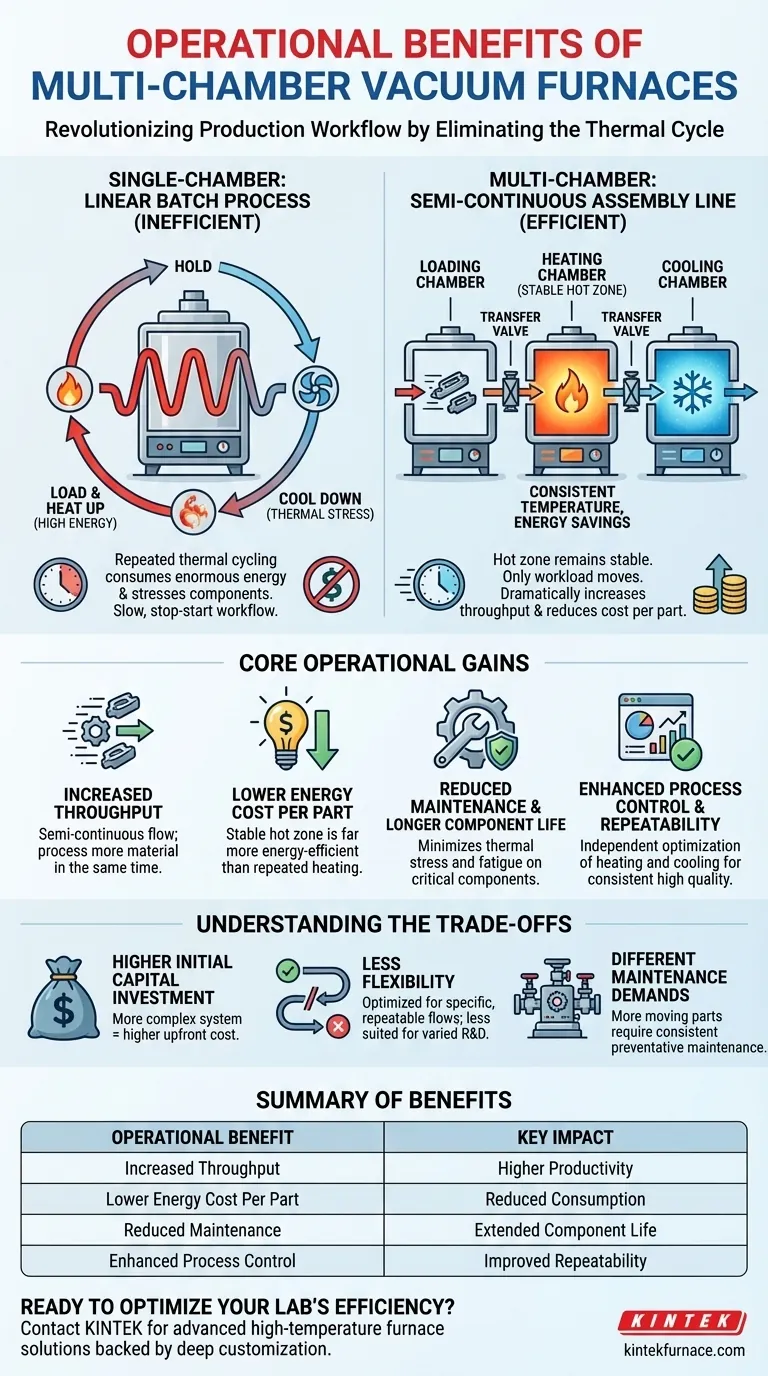

From an operational standpoint, multi-chamber vacuum furnaces deliver significant benefits by fundamentally changing the production workflow. Unlike single-chamber units that must complete a full heating and cooling cycle for every batch, multi-chamber designs use separate, dedicated chambers for each process step. This semi-continuous approach drastically increases throughput, lowers energy consumption per part, and reduces maintenance costs by keeping the hot zone at a stable operating temperature.

The primary value of a multi-chamber furnace is its ability to transform a stop-and-start batch process into a smooth, energy-efficient assembly line. By isolating the heating and cooling stages, you eliminate the most time-consuming and costly element of vacuum heat treating: the thermal cycle.

The Core Advantage: Eliminating the Thermal Cycle

The key difference between single and multi-chamber furnace operation lies in how they manage heat. This single distinction drives nearly all of the operational benefits.

The Inefficiency of the Single-Chamber Cycle

A single-chamber furnace operates in a linear batch process. The entire vessel and its internal components must be heated up with the workload, held at temperature, and then cooled back down before the next batch can be loaded.

This repeated thermal cycling is the primary source of operational inefficiency. It consumes enormous amounts of energy and puts significant stress on all furnace components.

The Multi-Chamber Paradigm Shift

A multi-chamber furnace operates more like an assembly line. It typically consists of a loading chamber, a heating chamber (the hot zone), and a cooling or quenching chamber.

The workload moves from one dedicated chamber to the next. Crucially, the hot zone is kept at a consistent operating temperature, while the cooling chamber remains cool. Only the workload moves, not the heat.

Translating Design into Operational Gains

By eliminating the thermal cycle, a multi-chamber design creates a cascade of benefits that directly impact your bottom line and production quality.

Drastically Increased Throughput

Because you are not waiting for a single chamber to heat up and cool down, a new batch can be introduced into the furnace as soon as the previous one has moved from the hot zone to the cooling chamber.

This semi-continuous flow dramatically increases throughput and productivity, allowing you to process more material in the same amount of time.

Lower Energy Cost Per Part

Maintaining a stable temperature is far more energy-efficient than repeatedly heating a massive thermal mass from ambient temperature.

By retaining the stored heat in the hot zone, the energy cost per pound of processed material is significantly lower, leading to substantial long-term operational savings.

Reduced Maintenance and Longer Component Life

Thermal cycling is the leading cause of wear and tear on furnace components like heating elements, insulation, and hearth supports. The constant expansion and contraction lead to fatigue, brittleness, and eventual failure.

By keeping the hot zone stable, a multi-chamber furnace minimizes this stress, significantly reducing maintenance costs and extending the life of critical, expensive components.

Enhanced Process Control and Repeatability

Separating the heating and cooling processes allows for independent optimization of each stage. You gain finer control over heating rates, soak times, and quenching parameters without compromise.

This separation, often managed by advanced PLC and HMI systems, results in superior process repeatability and consistently higher-quality finished parts.

Understanding the Trade-offs

While the operational benefits are clear, a multi-chamber system is not the default choice for every application. Understanding its trade-offs is crucial for making an informed decision.

Higher Initial Capital Investment

A multi-chamber furnace is a more complex system with more components, including transfer mechanisms, additional vacuum pumps, and sophisticated controls. This results in a significantly higher upfront cost compared to a single-chamber unit of similar size.

Less Flexibility for Varied Processes

These systems are optimized for a specific, repeatable process flow. They are less flexible than single-chamber furnaces for one-off jobs or R&D work that requires frequent changes to temperature profiles and process parameters.

Different Maintenance Demands

While maintenance from thermal stress is reduced, the mechanical complexity is higher. The system has more moving parts, valves, and seals that require a consistent preventative maintenance strategy to ensure reliable operation.

Making the Right Choice for Your Operation

The decision to invest in a multi-chamber vacuum furnace should be driven by your specific production goals and operational strategy.

- If your primary focus is high-volume, repeatable production: The multi-chamber furnace is the definitive choice for maximizing throughput and achieving the lowest cost-per-part.

- If your primary focus is processing diverse, low-volume batches: The flexibility and lower initial cost of a single-chamber furnace may be more suitable for your operational needs.

- If your primary focus is minimizing long-term operational costs for a consistent workload: The significant energy and maintenance savings of a multi-chamber system will deliver a superior total cost of ownership over the equipment's lifespan.

Ultimately, choosing the right furnace is a strategic decision about aligning your capital equipment with your long-term production and financial goals.

Summary Table:

| Operational Benefit | Key Impact |

|---|---|

| Increased Throughput | Enables semi-continuous processing for higher productivity |

| Lower Energy Cost Per Part | Reduces energy consumption by maintaining stable hot zone temperatures |

| Reduced Maintenance | Extends component life by minimizing thermal cycling stress |

| Enhanced Process Control | Improves repeatability with independent heating and cooling optimization |

Ready to optimize your lab's efficiency with advanced high-temperature furnace solutions? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with multi-chamber vacuum furnaces, tube furnaces, and more, backed by deep customization to meet your unique needs. Contact us today to discuss how our solutions can boost your throughput and reduce operational costs!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing