The fundamental difference between vacuum hardening and conventional hardening lies in the environment where the metal is heated. Conventional hardening heats parts in an atmosphere containing oxygen, while vacuum hardening heats them in a controlled, oxygen-free vacuum. This single distinction is the source of significant differences in surface quality, dimensional stability, and the need for post-processing.

The choice between vacuum and conventional hardening is not just about making a part harder; it's a strategic decision that dictates the final surface integrity, dimensional precision, and overall manufacturing cost of your component.

How Conventional Hardening Sets the Baseline

Conventional, or "normal," hardening involves heating a steel component to a critical temperature in an open furnace and then rapidly cooling (quenching) it in a medium like air, oil, or water.

The Challenge of Atmospheric Exposure

During heating, the oxygen in the atmosphere reacts with the hot surface of the metal. This process, known as oxidation, forms a dark, flaky layer of scale.

This scale is undesirable as it changes the part's surface texture and dimensions. It must be removed through secondary operations like sandblasting, grinding, or chemical pickling, which add time and cost to the manufacturing process.

The Vacuum Hardening Advantage: Total Environmental Control

Vacuum hardening performs the same function—heating and quenching—but does so inside a sealed chamber from which nearly all atmosphere has been removed. High-pressure inert gas, like nitrogen, is then used for quenching.

Eliminating Oxidation for a "Bright" Finish

By removing oxygen, vacuum hardening completely prevents oxidation and scale formation.

Parts emerge from the furnace with a clean, bright, and metallic surface, identical to how they went in. This often eliminates the need for any post-treatment cleaning or surface finishing.

Ensuring Unmatched Dimensional Stability

The controlled, uniform heating and gas-based quenching inside a vacuum furnace minimize thermal shock. This results in significantly less distortion, warping, and dimensional change compared to the more aggressive liquid quenching of conventional methods.

For parts with tight tolerances, such as injection molds, dies, and precision gears, this stability is non-negotiable.

Achieving Superior Metallurgical Purity

The vacuum environment actively pulls contaminants from the metal's surface, leading to a purer and more consistent metallurgical structure. This level of control allows for highly repeatable results and optimal material properties, which is critical for high-performance alloys.

Understanding the Practical Trade-offs

While vacuum hardening offers clear advantages, it is not the universal solution. The right choice depends on your material, part complexity, and budget.

Surface Quality vs. Upfront Cost

Conventional hardening has a lower initial process cost, but it incurs "hidden" costs in post-treatment cleaning and dealing with part distortion.

Vacuum hardening has a higher upfront cost due to the specialized equipment. However, it can reduce total manufacturing costs by eliminating secondary operations and minimizing part rejection rates.

Process Suitability and Material Type

Conventional hardening is versatile and effective for a wide range of common and low-alloy steels. Aggressive quenches like water are necessary for materials with low hardenability.

Vacuum hardening's gas quenching is less severe, making it ideal for air-hardening and oil-hardening tool steels and other high-alloy materials. It is not suitable for steels that require an extremely rapid water quench to achieve full hardness.

Making the Right Choice for Your Goal

Select your heat treatment method based on the final requirements of the component.

- If your primary focus is cost-effectiveness on simple, low-alloy parts where surface finish is not critical: Conventional hardening is a practical and economical choice.

- If your primary focus is preserving intricate details, tight tolerances, and a pristine surface finish: Vacuum hardening is the superior and often essential method.

- If your primary focus is achieving maximum consistency and performance from high-value alloys: The precise control of vacuum hardening provides unparalleled repeatability and metallurgical purity.

By understanding the environment in which your part is treated, you gain direct control over its final quality, performance, and cost.

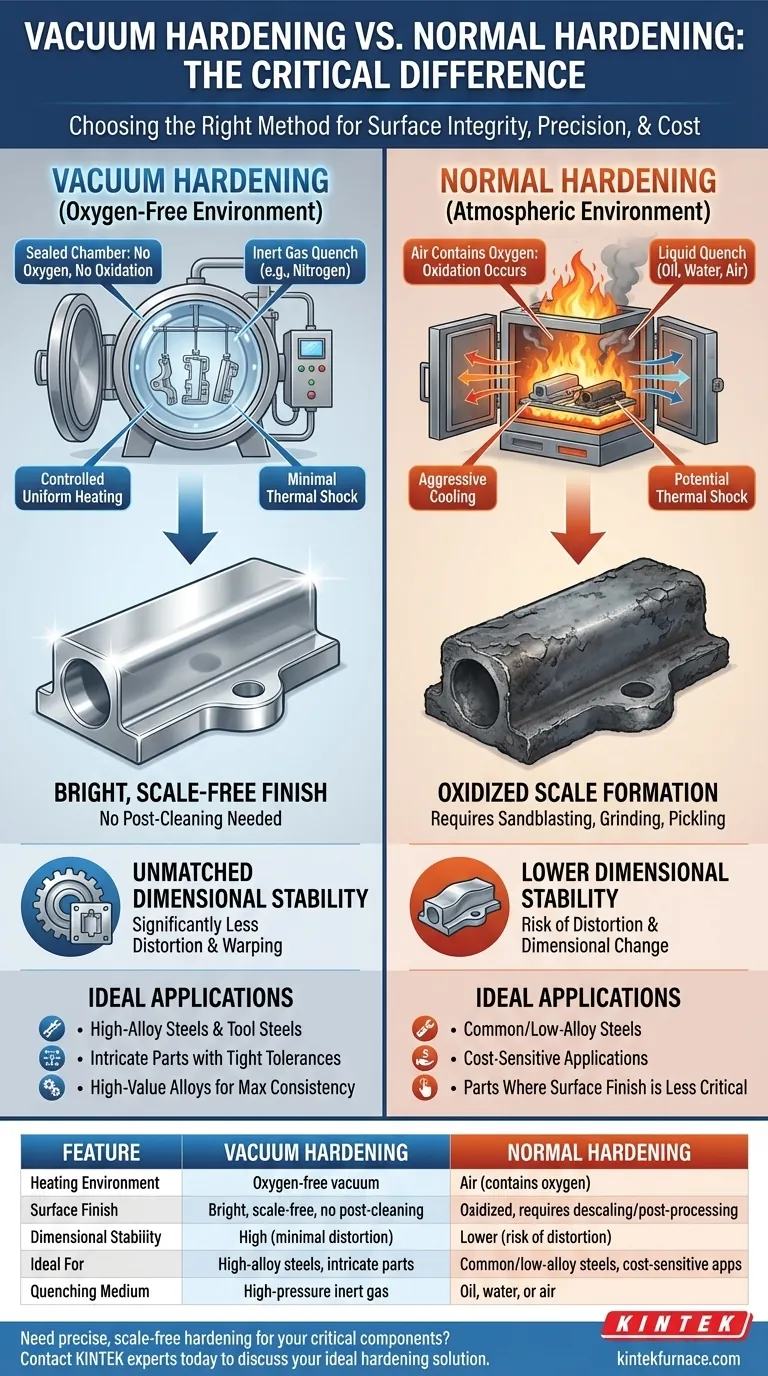

Summary Table:

| Feature | Vacuum Hardening | Normal Hardening |

|---|---|---|

| Heating Environment | Oxygen-free vacuum | Air (contains oxygen) |

| Surface Finish | Bright, scale-free, no post-cleaning | Oxidized, requires descaling/post-processing |

| Dimensional Stability | High (minimal distortion/warping) | Lower (risk of distortion) |

| Ideal For | High-alloy steels, intricate parts, tight tolerances | Common/low-alloy steels, cost-sensitive applications |

| Quenching Medium | High-pressure inert gas (e.g., Nitrogen) | Oil, water, or air |

Need precise, scale-free hardening for your critical components?

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories and production facilities with advanced high-temperature furnace solutions. Our product line, including Vacuum & Atmosphere Furnaces, is complemented by our strong deep customization capability to precisely meet your unique heat treatment requirements—ensuring superior surface integrity, dimensional stability, and repeatable results for your high-value alloys.

Contact our experts today to discuss the ideal hardening solution for your application.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in TBC post-processing? Enhance Coating Adhesion

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the proper procedures for handling the furnace door and samples in a vacuum furnace? Ensure Process Integrity & Safety