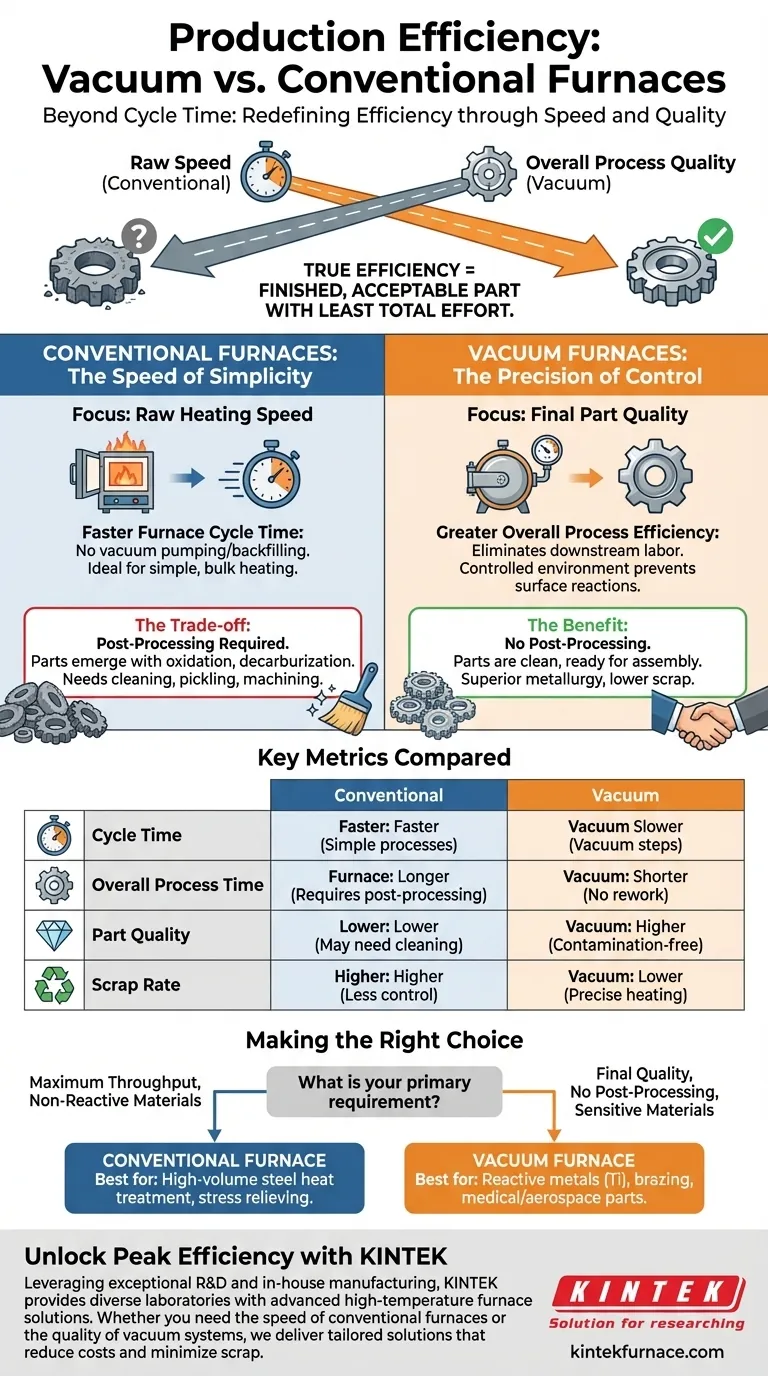

Directly comparing the production efficiency of vacuum and conventional furnaces is misleading because the term "efficiency" means different things in each context. While a conventional furnace may complete a raw heating and cooling cycle faster, a vacuum furnace often provides far greater overall process efficiency by delivering a higher quality, finished part that requires no rework or secondary cleaning operations.

The core issue is not which furnace is faster, but which process delivers a finished, acceptable part with the least total effort. Conventional furnaces prioritize raw heating speed, while vacuum furnaces prioritize final part quality, often eliminating entire post-processing steps.

Redefining "Production Efficiency": Speed vs. Quality

To make an informed decision, you must look beyond the simple metric of cycle time and evaluate efficiency across the entire production workflow, from raw material to finished part.

The Obvious Metric: Furnace Cycle Time

Conventional furnaces often have an advantage in raw cycle time. They do not require the additional steps of pumping down to a vacuum and then backfilling with an inert gas.

This makes their heating and cooling cycles appear faster on paper, especially for simple annealing or tempering of large workpieces.

The Critical Metric: Overall Process Time

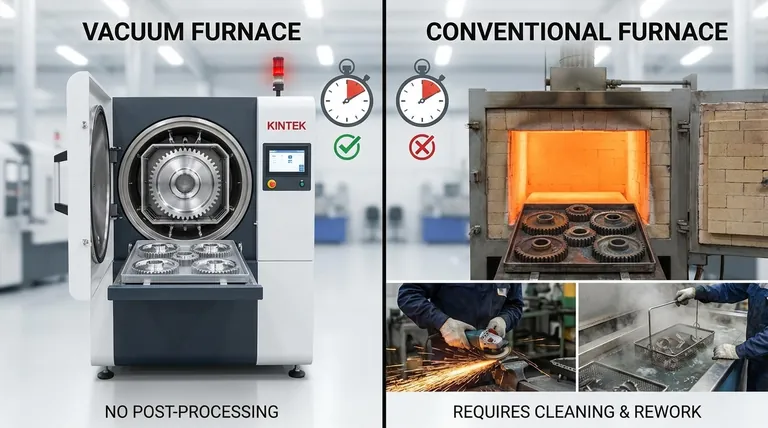

Vacuum furnaces excel by eliminating downstream labor. Because they operate in a controlled, contamination-free environment, they prevent oxidation, decarburization, and other unwanted surface reactions.

This means parts emerge from the furnace clean and ready for the next assembly step, completely removing the need for post-processing like sandblasting, acid pickling, or machining to remove a damaged surface layer.

The Impact of Final Part Quality

Vacuum furnaces provide exceptionally uniform heating and precise temperature control. This controlled environment results in superior metallurgical properties, such as improved material density, reduced porosity, and enhanced strength.

This level of quality control dramatically reduces rejection and scrap rates, a factor that significantly impacts true production efficiency and cost.

How Each Furnace Type Achieves Its Results

The efficiency differences stem directly from the fundamental operational principles of each furnace technology.

Conventional Furnaces: The Speed of Simplicity

These furnaces heat parts in the ambient atmosphere or a simple protective gas. Their design is straightforward, making them easy to operate and suitable for a wide range of general-purpose industrial applications.

Their strength lies in processing large volumes of non-reactive materials where surface finish is not the primary concern.

Vacuum Furnaces: The Precision of a Controlled Environment

By removing atmospheric gases, a vacuum furnace creates a pure environment for thermal processing. This is critical for preventing unwanted chemical reactions with the part's surface.

This precision is what makes vacuum furnaces essential for high-value processes like brazing and for treating sensitive, reactive metals like titanium and high-purity alloys.

Not All Vacuums Are Equal

The term "vacuum furnace" covers a range. Low-vacuum furnaces have faster pump-down and overall cycle times, offering a balance of speed and quality.

High-vacuum and ultra-high-vacuum furnaces are slower due to the extensive time required to achieve a near-perfect vacuum, a necessity for the most demanding aerospace, medical, and electronics applications.

Understanding the Critical Trade-offs

Choosing the wrong furnace type based on a single metric like cycle time can introduce significant hidden costs and production bottlenecks.

The Case for Conventional Furnaces

A conventional furnace is often the most cost-effective choice for high-volume heat treatment of standard steels and alloys where some surface oxidation is acceptable or easily removed.

For simple processes like stress-relieving large fabrications, their speed and simplicity are unmatched.

The Non-Negotiable Case for Vacuum Furnaces

For any process involving reactive metals, high-carbon steels where decarburization is a risk, or joining components via brazing, a vacuum furnace is not optional.

In these applications, the "slower" cycle is the necessary price for achieving the required metallurgical properties and ensuring the integrity and safety of the final product.

The Hidden Costs of a "Faster" Cycle

Opting for a conventional furnace to save time can lead to significant downstream costs. You must budget for the labor, equipment, and time required for post-treatment cleaning.

Furthermore, a less-controlled process inevitably leads to a higher scrap rate, which can quickly erase any perceived savings from a faster furnace cycle.

Making the Right Choice for Your Application

Your decision must be based on the final requirements of your part, not just the speed of one manufacturing step.

- If your primary focus is maximum throughput for non-sensitive materials: A conventional furnace often provides the fastest raw furnace cycle time for bulk processing.

- If your primary focus is final part quality and eliminating post-processing: A vacuum furnace delivers superior results and a more efficient end-to-end workflow.

- If you are working with reactive metals, brazing, or parts for medical/aerospace: A vacuum furnace is the only technology that can meet the necessary quality and safety standards.

Ultimately, true production efficiency is measured not by the speed of a single step, but by the total time, cost, and effort required to produce a finished part that meets specification.

Summary Table:

| Metric | Conventional Furnace | Vacuum Furnace |

|---|---|---|

| Cycle Time | Faster for simple processes | Slower due to vacuum steps |

| Overall Process Time | Longer with post-processing | Shorter, no rework needed |

| Part Quality | Lower, may require cleaning | Higher, contamination-free |

| Scrap Rate | Higher due to less control | Lower with precise heating |

| Best For | High-volume, non-reactive materials | Reactive metals, brazing, high-quality applications |

Unlock Peak Efficiency with KINTEK's Advanced Furnace Solutions

Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you need the speed of conventional furnaces or the quality of vacuum systems, we deliver tailored solutions that reduce costs, minimize scrap, and eliminate post-processing. Contact us today to discuss how we can optimize your heat treatment process and boost your production efficiency!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- Why does heating steel rod bundles in a vacuum furnace eliminate heat transfer paths? Enhance Surface Integrity Today

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today